Method for preparing calcium carbide and synthetic gas via flameless oxidation heating method, and calcium carbide reactor

A flameless oxidation and reactor technology, applied in the direction of carbide, calcium carbide, fixed bed gasification, etc., can solve the problem that high temperature refractory materials cannot meet the use requirements, affect the reaction time and effect of calcium carbide, and cannot achieve high temperature resistance and long life, etc. problem, to achieve the effect of increasing the reaction rate of calcium carbide, solving uneven heat distribution, and good preheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

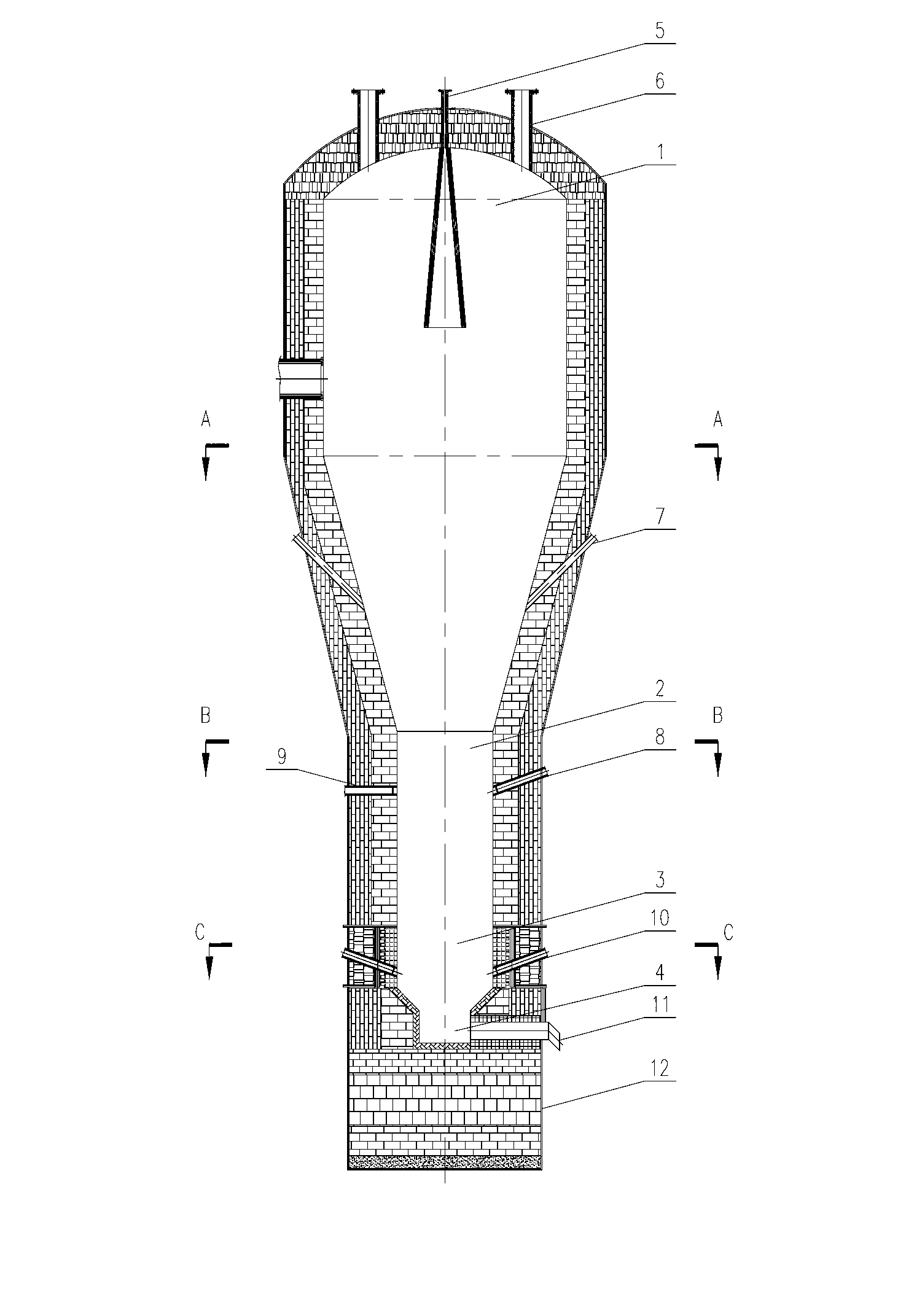

[0043] Carbide reactor embodiment:

[0044] see Figure 1-4 The calcium carbide reactor of the present invention comprises a closed reaction furnace, and the closed reaction furnace is composed of an upper quenching chamber 1, a gasification chamber 2 in the middle, a lower reaction chamber 3 and a calcium carbide pool 4 at the bottom, and the quenching chamber 1 The top is provided with an air outlet 6, a first feed port 5, and a plurality of second feed ports 7 are arranged on the side wall. The feed port 7 is arranged in the same cross-section facing and uniform; the gasification chamber 2 is provided with a start-up ignition combination burner 9 and a plurality of oxygen burners 8, and the plurality of oxygen burners 8 are evenly distributed along the circumferential direction and radially positive. Yes, the downward inclination angle is 10-30°; a plurality of oxygen burners 10 are evenly arranged along the circumferential direction in the reaction chamber 3, and the plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com