Dry-method coating layer production technology for label cloth

A production process and label tape technology, applied in the field of fabric processing technology and label tape dry coating production technology, can solve the problems of high temperature resistance, coating peeling, etc., to improve quality, save costs, and solve the problem of coating peeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

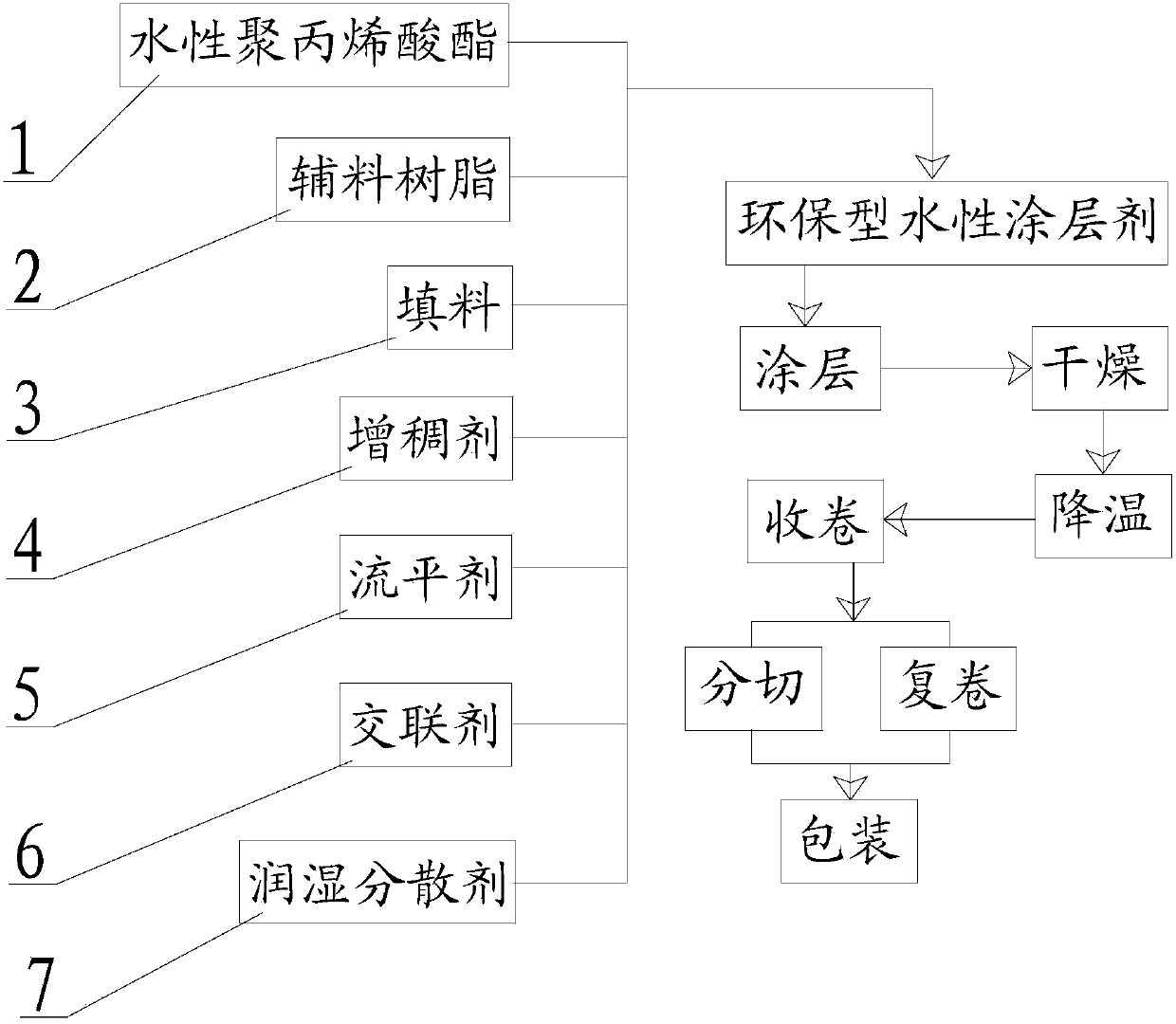

[0013] refer to figure 1 , a kind of trademark tape dry coating production process of the present invention, configure raw material by following weight ratio: water-based polyacrylate 1, crosslinking agent 6, filler 3, wetting and dispersing agent 7, thickener 4, leveling agent 5 The weight ratio with the auxiliary material resin 2 is (40~60):(1~3):(15~22):(1~2):(3~8):(0.3~0.8):(0.2~1); After the raw materials are prepared, 5% to 15% of water is added according to the quality of the raw materials; the raw materials and water are stirred by a stirrer to mix the raw materials evenly to make a coating material; the coating material is evenly mixed by a trademark belt coating machine Coating on non-woven fabrics; drying the label tape through a dryer; cooling the label tape through refrigeration equipment; after winding through a winder, cutting by a cutter, and then rewinding; packaging through a packaging machine. Before the raw materials and water are stirred by a stirrer, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com