Realization method of air gap clad optical fiber

A technology of air gap and implementation method, which is applied in cladding optical fibers, multi-layer core/cladding optical fibers, optical waveguides and light guides, etc. problem, to achieve the effect of mature technology, lower production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

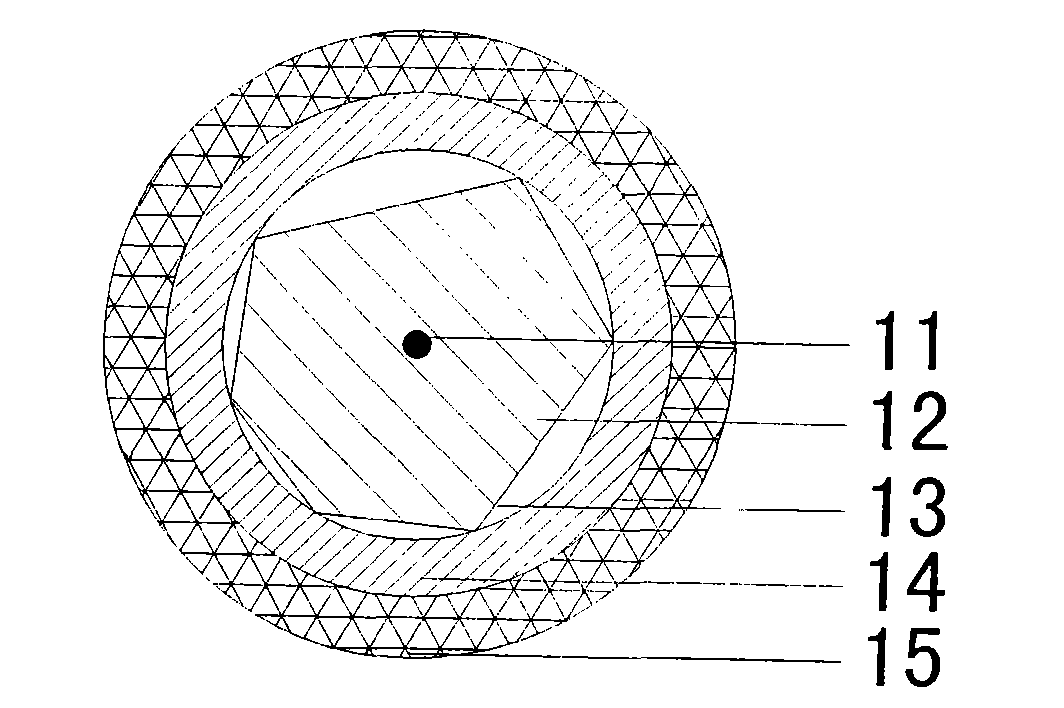

[0019] attached figure 1 It is the heterohexagonal straight-sided air cladding ytterbium-doped double-clad optical fiber of the first embodiment of the present invention, the periphery of the ytterbium-doped fiber core 11 is a pure silica hexagonal inner cladding 12, and the outer cladding 12 is an air cladding layer 13, followed by an inner protective layer 14 of quartz over which is covered an outer protective layer 15 of UV-cured acrylic resin. In this embodiment, the MCVD process and the high-temperature gas-phase doping process are used to manufacture the ytterbium-doped fiber core inner cladding preform, the rod diameter is 32mm, and the length is 500mm; then the fiber core inner cladding preform is formed into a heterohexagon by optical cold processing A quartz tube is placed on the core preform as the inner protective layer 14, with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com