Preparation methods for thermoelectric colloid material and thermoelectric device, and product

A thermoelectric device and colloidal material technology, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric devices, and thermoelectric device junction lead wire materials, etc., can solve the problems of difficult encapsulation and integration of thermoelectrochemical devices, and achieve the effect of easy encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The method for preparing thermoelectric colloid provided in Example 1 includes the following steps:

[0034] (1) Dissolve 4g of polymer powder in 40mL of water at 80°C to obtain a clear polymer solution;

[0035] (2) When the above polymer solution is clarified, pour 10mL of 0.1M FeCl at a rate of 0.1mL / s 2 / FeCl 3 (containing 1mL HCl, to prevent hydrolysis) was slowly added to the above clear polymer solution, and stirred evenly at a stirring speed of 200 rpm to obtain PVA-FeCl 2 / FeCl 3 colloid;

[0036] (3) The above-mentioned PVA-FeCl2 / FeCl3 colloid is solidified by a mold to make a cylindrical colloid with a diameter of 3 mm and a thickness of 1 mm.

[0037] The thermoelectric colloid prepared in Example 1 is encapsulated between two chromium-gold electrodes by polydimethylsiloxane (PDMS) to obtain a thermoelectric device; wherein, the chromium-gold electrode is plated on a PI (polyimide, polyimide) film superior.

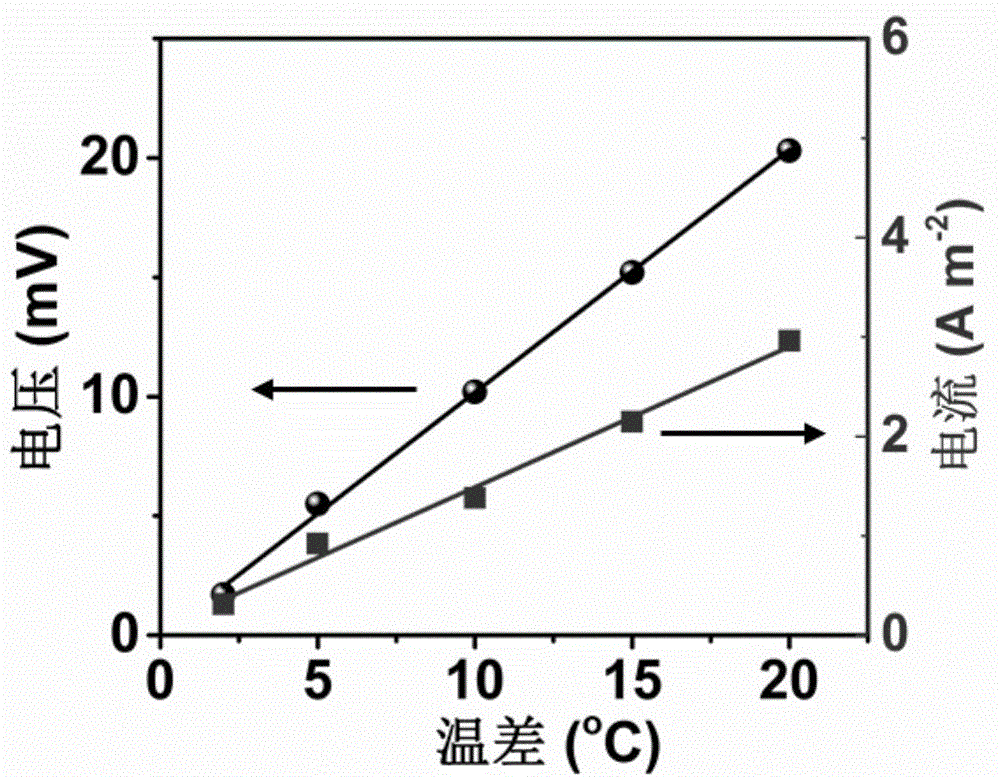

[0038] figure 1 Shown, is the PVA-FeCl tha...

Embodiment 2

[0040] The method for preparing thermoelectric colloid provided in Example 2 includes the following steps:

[0041](1) Dissolve 4g of polyvinyl alcohol in 400mL of water at 85°C to obtain a polymer solution;

[0042] (2) When the above polymer solution is clarified, 10mL of 0.1M K at a speed of 0.07mL / s 4 Fe(CN) 6 / K 3 Fe(CN) 6 Slowly add to the clear polymer solution, stir at a stirring speed of 300 rpm to dissolve it evenly, and obtain PVA-K 4 Fe(CN) 6 / K 3 Fe(CN) 6 colloid;

[0043] (3) The above-mentioned PVA-K is molded into 4 Fe(CN) 6 / K 3 Fe(CN) 6 The colloid is solidified to make a cylindrical colloid with a diameter of 3mm and a thickness of 1mm;

[0044] The thermoelectric colloid prepared in Example 2 was encapsulated between two chrome-gold electrodes with polydimethylsiloxane (PDMS) to obtain a thermoelectric device; wherein, the chrome-gold electrodes were plated on the PI film.

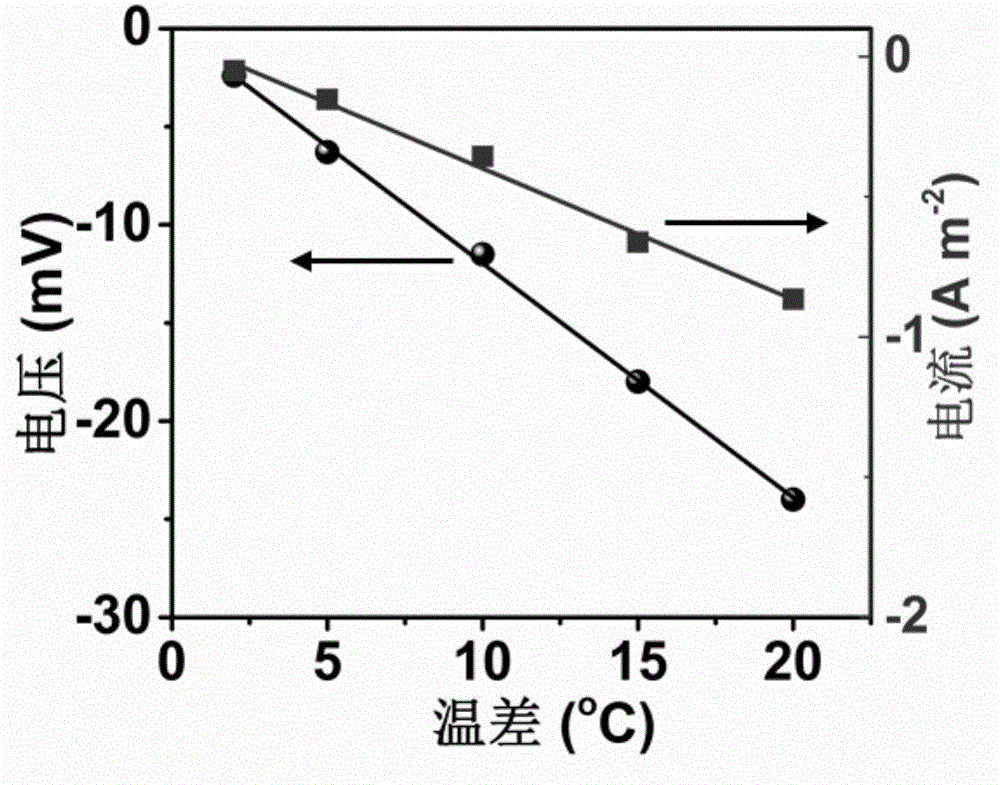

[0045] Utilize the prepared PVA-K of the preparation method of embodim...

Embodiment 3

[0048] In order to further improve the thermoelectric output performance of the thermoelectric device, increase the output voltage and current, the PVA-FeCl prepared in Example 1 2 / FeCl 3 PVA-K prepared by thermoelectric device and embodiment 2 4 Fe(CN) 6 / K 3 Fe(CN) 6 Thermoelectric devices perform as Figure 4 The integration process shown includes the following steps:

[0049] (1) Depositing cross-chromium-gold electrodes on the PI flexible substrate;

[0050] (2) Arrange 59 PVA-FeCl in sequence on the cross chrome-gold electrodes 2 / FeCl 3 Colloidal cylinder and 59 PVA-K 4 Fe(CN) 6 / K 3 Fe(CN) 6 Colloidal cylinder, get middleware;

[0051] (3) Encapsulate the surrounding of the above middleware with PDMS to obtain a wearable flexible thermoelectric device;

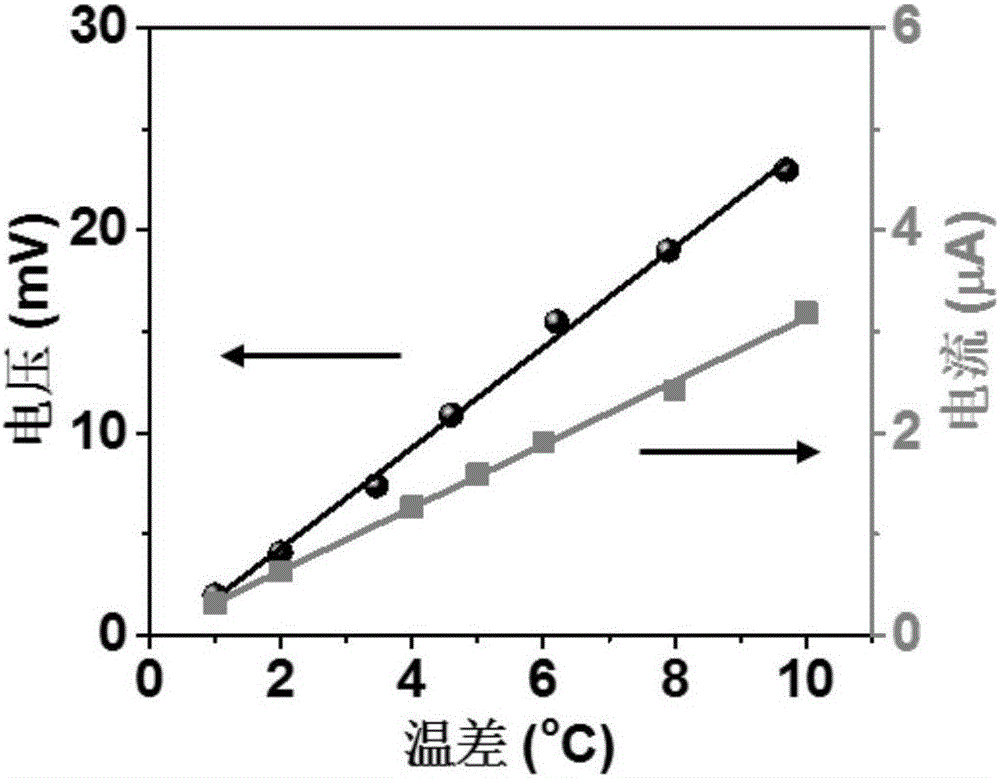

[0052] The wearable flexible thermoelectric device prepared by packaging in Example 3 can directly convert the heat energy of the human body into electrical energy. The schematic diagram of its thermoelec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Seebeck coefficient | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com