Improved heat quantity meter

A heat meter and quantity technology, applied in the direction of measuring heat, calorimeters, measuring devices, etc., can solve the problems of increased heat meter volume, unfavorable overall sealing, high manufacturing cost, etc., achieve compact structure, reduce overall volume, and reduce manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

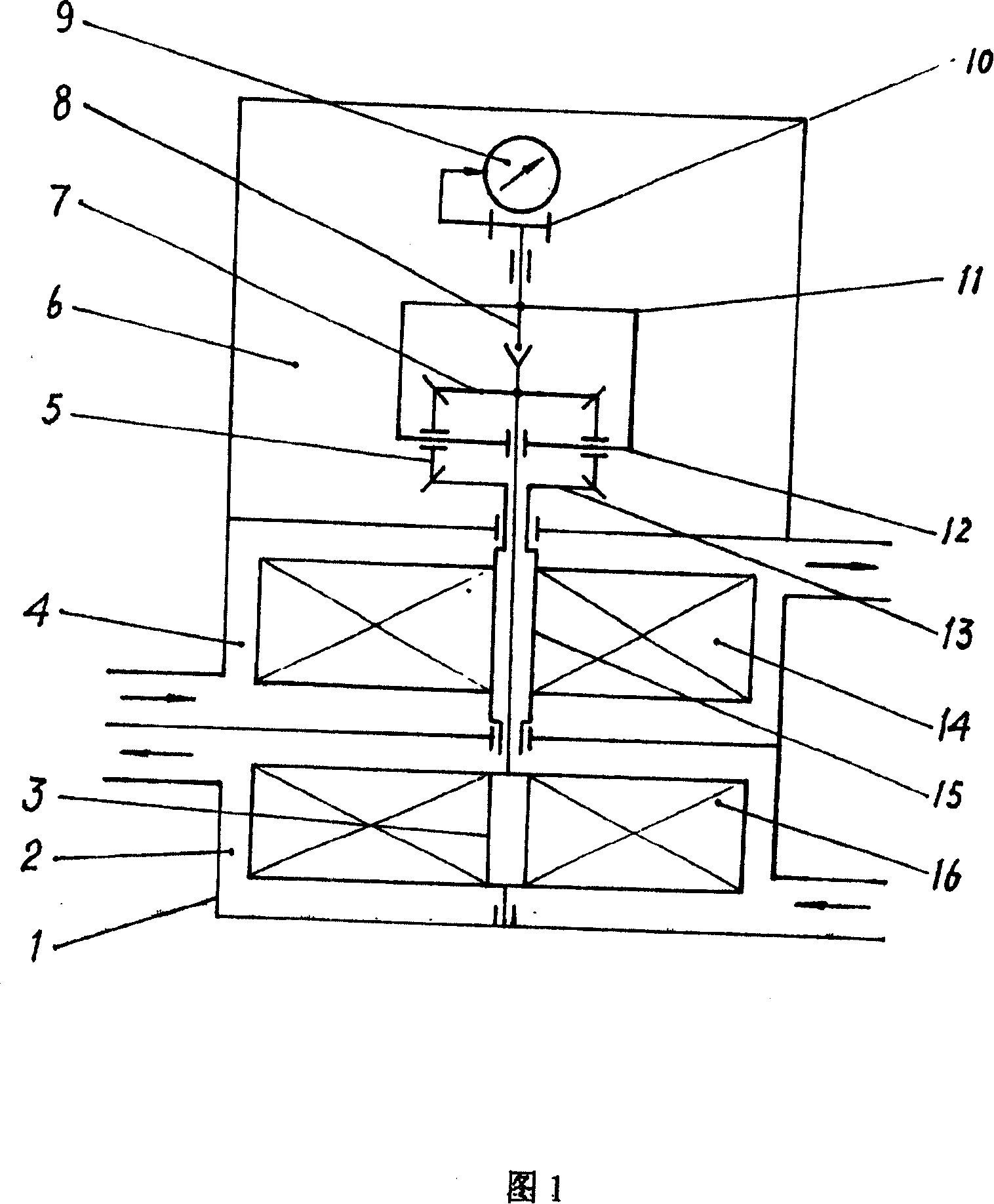

[0007] Embodiment: a kind of improved heat meter, the vane shape, size, quantity of two variable impellers are the same, and the vanes are made of bimetal material into a specific shape, and the fluids in the two cavities 2 and 4 of the impellers are housed The flow rate is the same, and there is another cavity 6 in the case 1 that is equipped with a transmission assembly 11 and a counting device 9. The transmission assembly 11 includes a differential gear transmission system, and the differential gear transmission system has two input terminals and an output terminal. The two impellers are respectively fixedly connected to the two input terminals of the differential gear transmission system through the transmission shaft, and the output terminals of the differential gear transmission system are connected to the counting device to drive the counting device to run.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com