Self-cooling high-power integral LED package

A LED packaging and high-power technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of low luminous efficiency of LED chips, LED current suppression fading, and large energy loss, so as to suppress fading phenomenon and improve luminous effect , the effect of area increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but the scope of implementation of the present invention is not limited thereto.

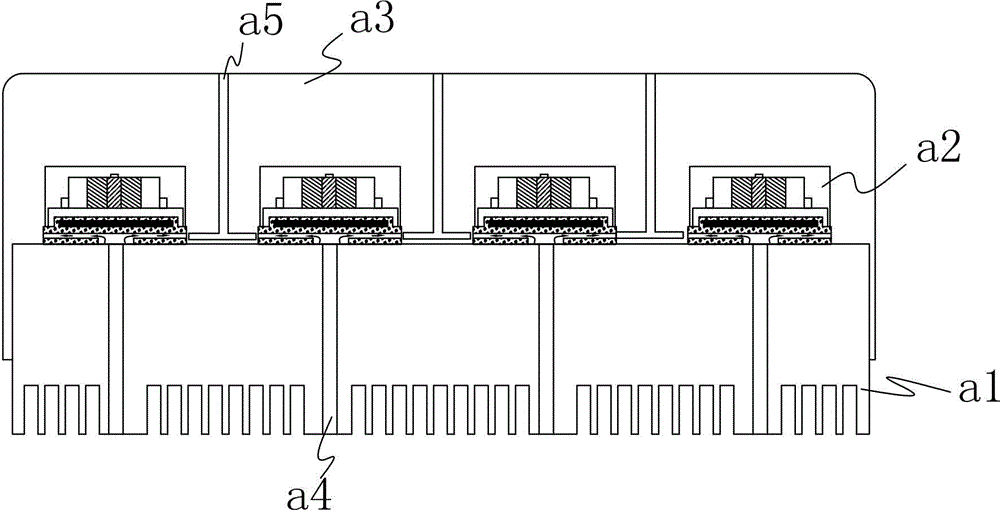

[0019] like Figures 1 to 2 As shown, the self-heating high-power integral LED package described in this embodiment includes a metal heat-dissipating base a1, and a plurality of LED epitaxial wafers a2 are arranged on the metal heat-dissipating base a1;

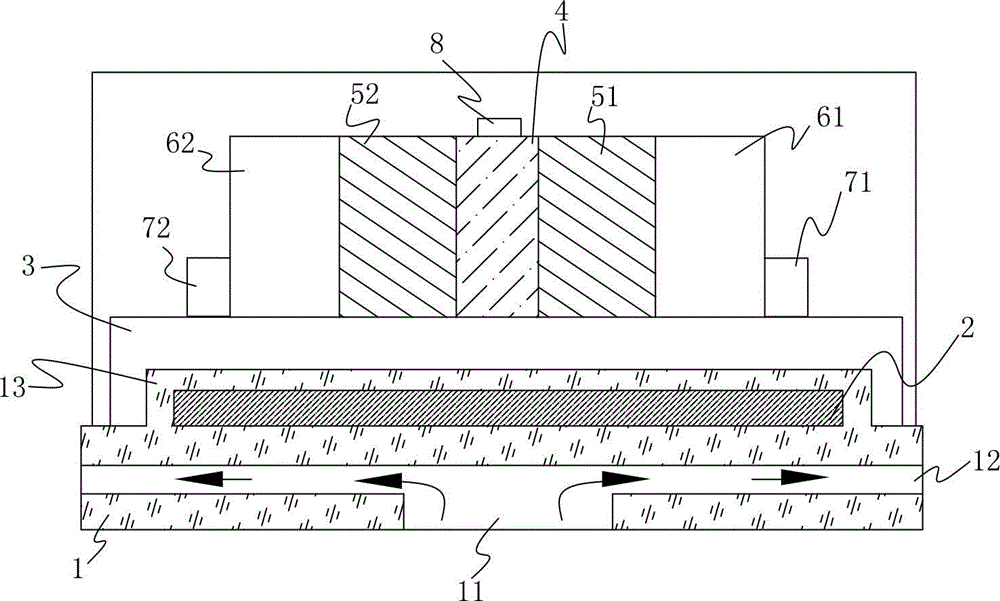

[0020] The LED outer edge sheet includes a metal substrate 1. The bottom surface of the metal substrate 1 is provided with air inlet openings 11, and both sides of the metal substrate 1 are provided with air outlet openings 12. The two air outlet openings 12 are communicated with the air inlet openings 11; a convex shell 13 extends from the top surface of the metal substrate 1, and the convex shell 13 is filled with a piezoelectric ceramic layer 2; the metal substrate 1 A GaN buffer layer 3 is provided ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com