Method for directly manufacturing cold cathode flat plate X-ray detector on scintillator and structure thereof

A cold cathode and scintillator technology, applied in the direction of electric solid devices, semiconductor devices, radiation intensity measurement, etc., can solve the problems of pixel point influence, easy pollution, scattering, etc., increase the number and energy of electrons, improve detection sensitivity, increase Effective voltage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

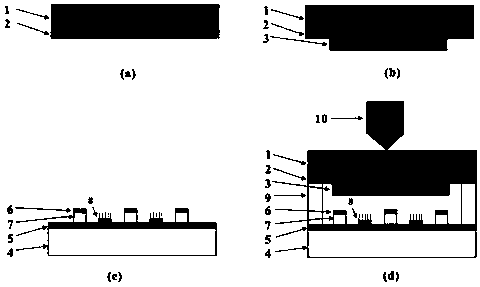

[0037] Please also see figure 1 (a)~ figure 1(d), a method for directly making a cold cathode flat-panel X-ray detector on a scintillator according to the present embodiment comprises the following process steps:

[0038] Step S1: Prepare a light-transmitting anode electrode 2 on one side of the scintillator 1, such as figure 1 (a) shown.

[0039] The scintillator 1 adopts materials capable of converting X-rays into visible light, and the materials include CsI, CaWO 4 , YTaO 4 、Gd 2 o 2 S. Bi 4 Ge 3 o 12 or Lu 2 SiO 5 . The anode electrode 2 formed by the ITO electrode was plated on one side of the scintillator by magnetron sputtering technology, the power during coating was 1.2KW, the coating rate was 14nm / min, and the thickness of the anode electrode 2 was 500nm. The anode electrode 2 is transparent to the light emitted by the scintillator, and is connected with a lead wire connected to the first external voltage source, and a voltage is applied to the anode elec...

Embodiment 2

[0053] This embodiment uses specific examples to describe in detail the detailed process of directly fabricating a cold-cathode flat-panel X-ray detector on a scintillator in the present invention.

[0054] (1) First, prepare a CsI scintillator with an area of 12.5cm×9.5cm and a thickness of 1mm. Then use the magnetron sputtering technology to plate the ITO electrode on the surface of the scintillator as an anode electrode. The thickness of the ITO electrode is 500nm, the coating power is 1.2KW, and the coating rate is 14nm / min. (2) Then, a ZnS photoconductor was plated on the middle area of the ITO electrode surface by electron beam evaporation technology, with a thickness of 4 μm, an area of 4.5 cm×8 cm, and a coating rate of 1 nm / s. (3) Next, an addressable cold cathode electron source is prepared on a glass substrate, the thickness of the glass substrate is 3 mm, and the area of the cold cathode electron source is 4.5 cm×8 cm. The cathode electrode strips and grid...

Embodiment 3

[0057] The difference between this example and Example 2 lies in the process of preparing the ZnS photoconductor on the anode electrode of the scintillator by using screen printing technology, and other steps are consistent with Example 2. The specific preparation process is as follows: first, the potassium silicate solution and ZnS powder are stirred evenly to form a ZnS melt; then the ZnS melt is prepared on the electrode on the scintillator by screen printing technology, with a thickness of 20 μm and an area of 4.5cm× 8cm; Finally, the above-prepared samples were dried on a hot plate. The preparation methods of other structures in this example are as described in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com