Ceiling joist and sliding rail integrated system

An integrated system and keel technology, applied in the direction of the ceiling, building components, hanging curtain devices, etc., can solve the problem that the corner of the slide rail and the connection between the corner and the main and auxiliary keels of the ceiling, the unreasonable setting of the ceiling keel structure and accessories, and the product The use of pulleys is not smooth and other problems, to achieve the effect of convenient maintenance or replacement of pulleys, high safety, and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

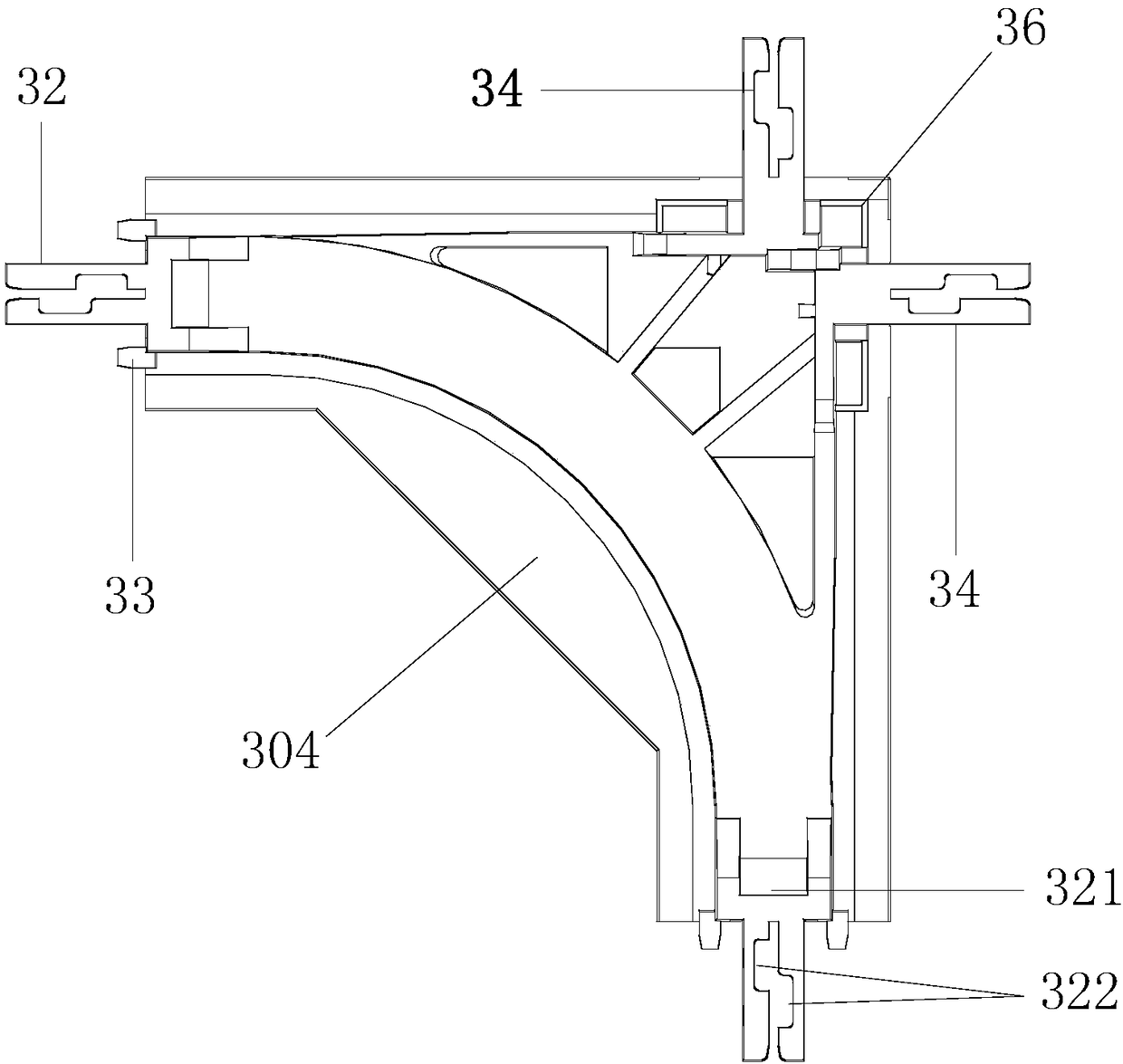

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in the preferred embodiment are only for convenience of description, and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

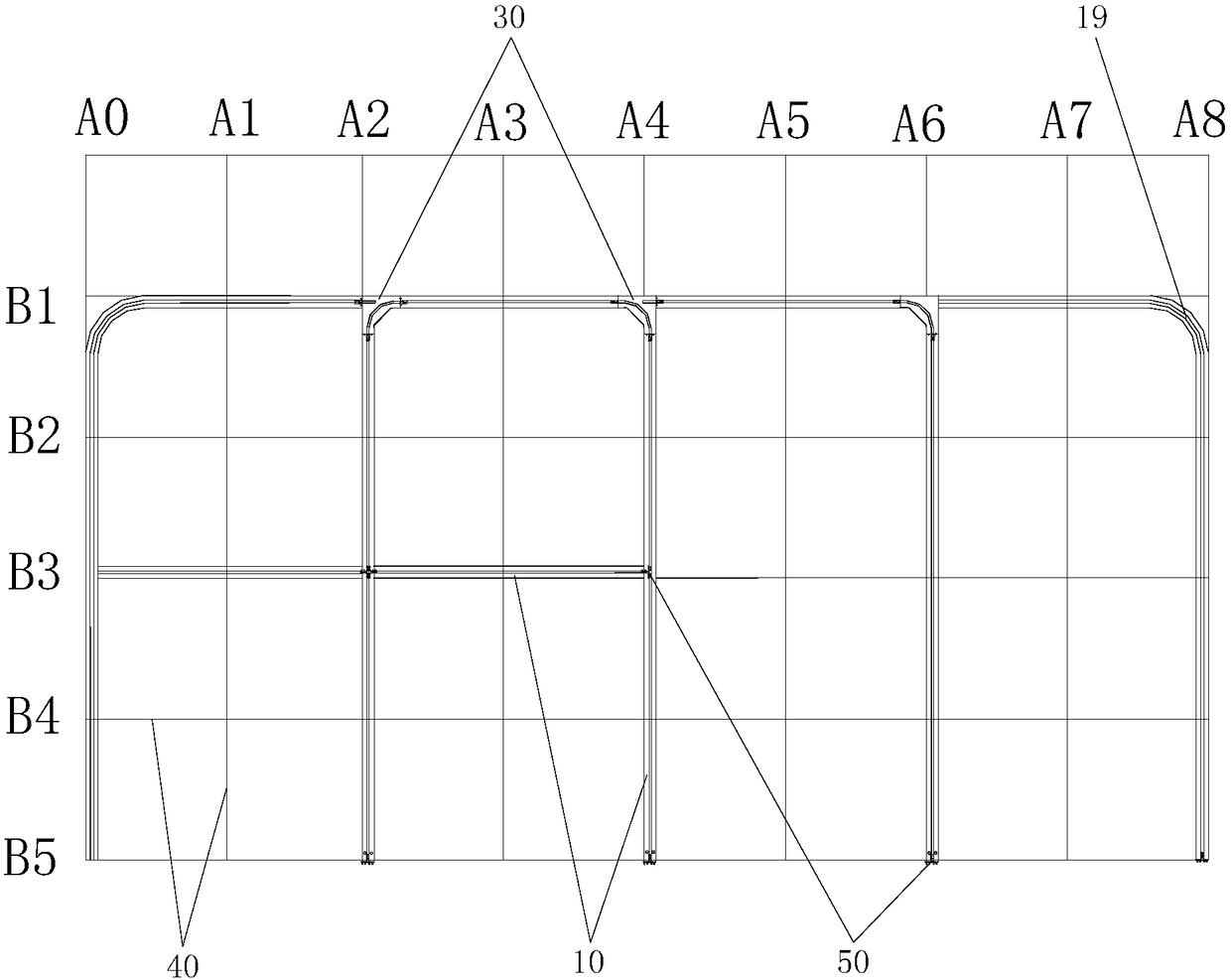

[0038] See figure 1 , a ceiling joist and slide rail integrated system designed in a preferred embodiment of the present invention, which mainly includes: a slide rail formed by a plurality of strip ceiling joists 10 staggered horizontally and vertically, and a pulley mounted on the slide rail. The following details Describe the components and their connections.

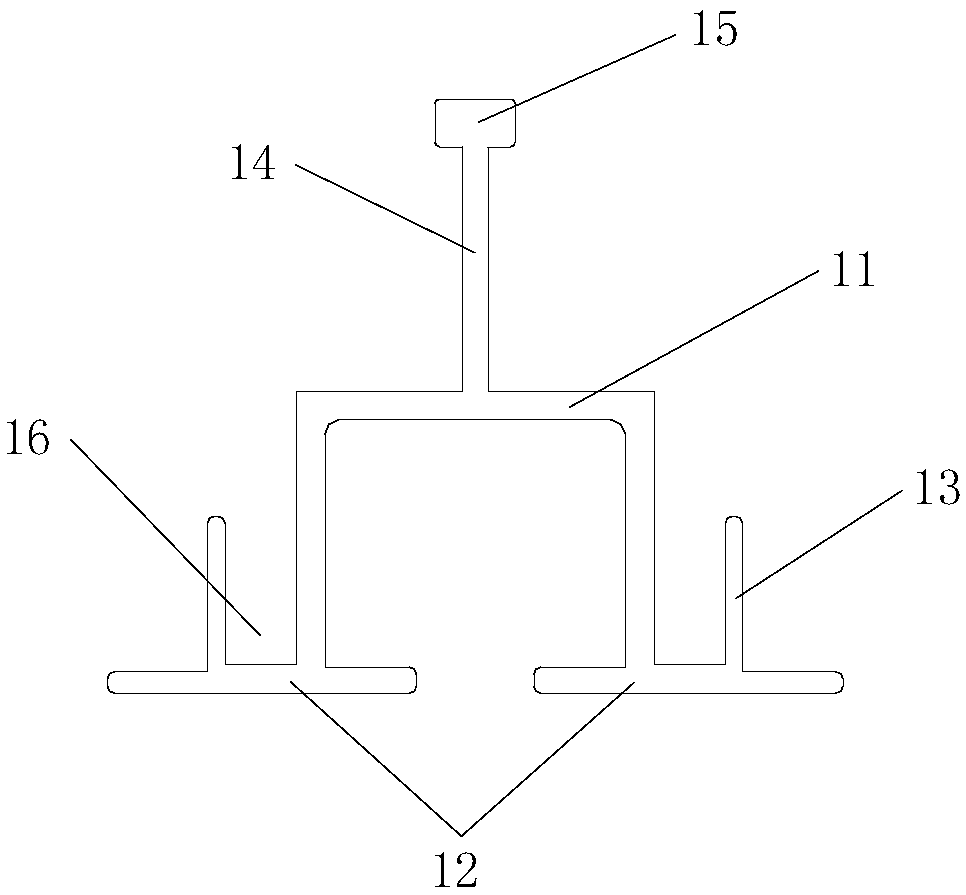

[0039] See figure 2 , The ceiling keel 10 includes: a wheel fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com