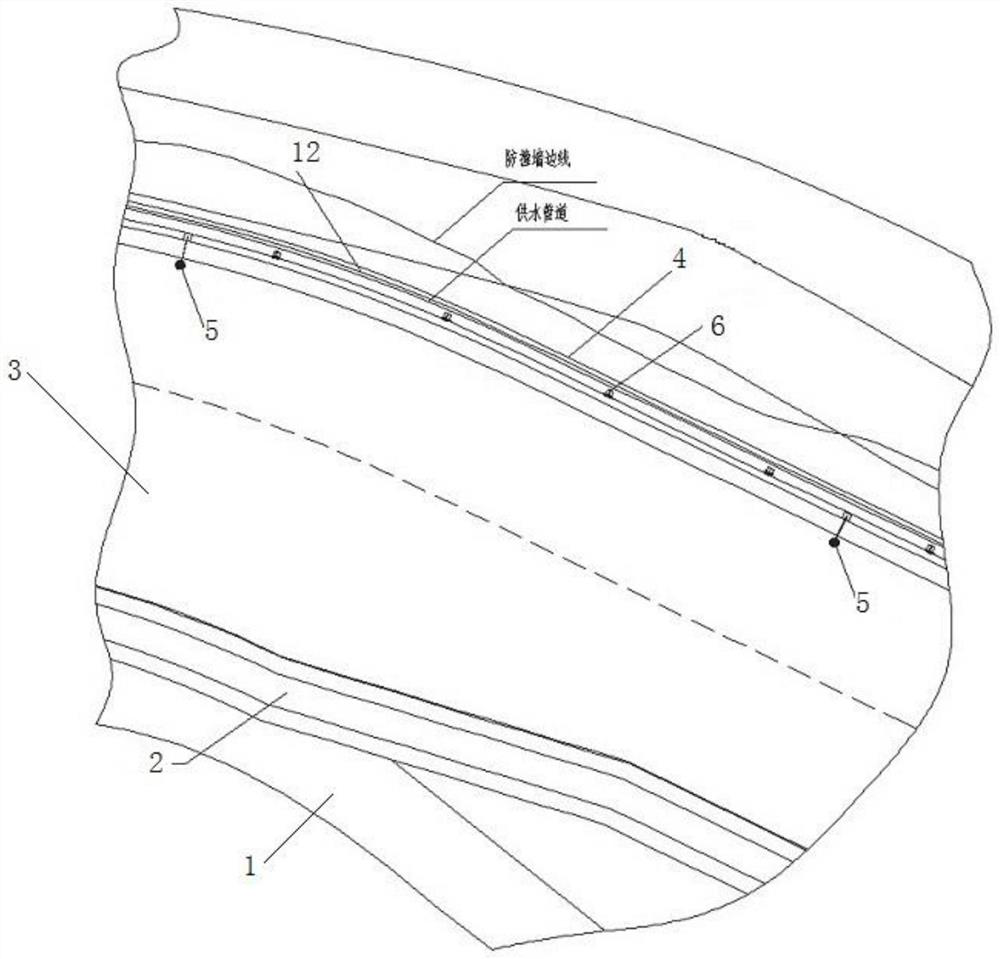

Road side adhesive pavement construction method for inhibiting flying dust and realizing environment-friendly transportation

A construction method, the technology of Bangjiao, is applied in the direction of road surface cleaning, on-site paved coagulation pavement, roads, etc., which can solve the problems of residents' pollution, asphalt deformation and damage, and cement pavement is easy to raise dust, etc., to solve the problem of long construction period, Suppresses dust and avoids the effect of easily raising dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

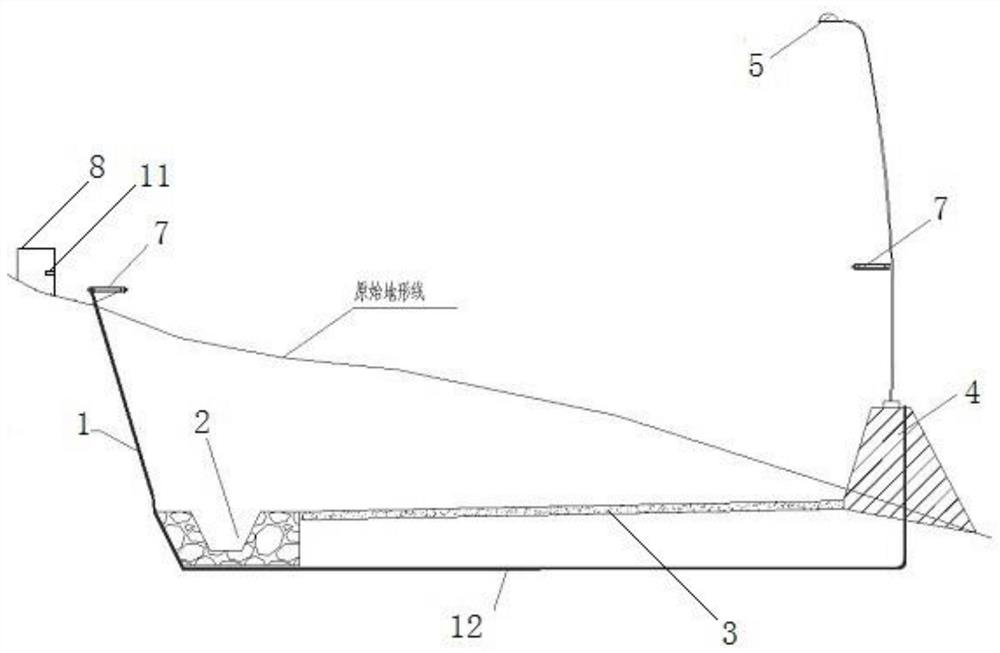

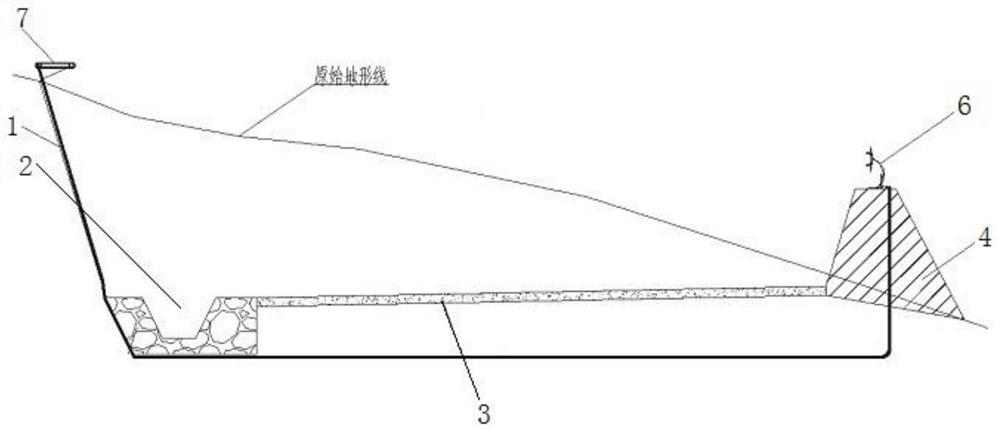

[0016] A roadbang rubber pavement construction method for suppressing dust and environmental protection transportation of the present invention comprises a construction process of a lower curing treatment layer and a construction process of an upper curing treatment layer;

[0017] The construction process of the lower solidification treatment layer includes:

[0018] Prepare the crushed stone layer: lay the crushed stone on the roadbed, and use a 12t or more road roller to statically roll it until there are no wheel marks on the surface of the crushed stone layer to ensure the proper road arch;

[0019] As preferably, the anti-seepage geomembrane is paved on the gravel layer, and after laying, it is pressed with a sand bag, and the solidified soil is paved after welding between the anti-seepage geomembrane, and the permeable geome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com