Small mechanical trip type thermal protection piezoresistor

A varistor and thermal protection technology, applied in varistor, overvoltage protection resistors, resistors, etc., can solve the problems of large volume, complex structure, limited application occasions, etc. The effect of fast buckle speed and short air arcing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

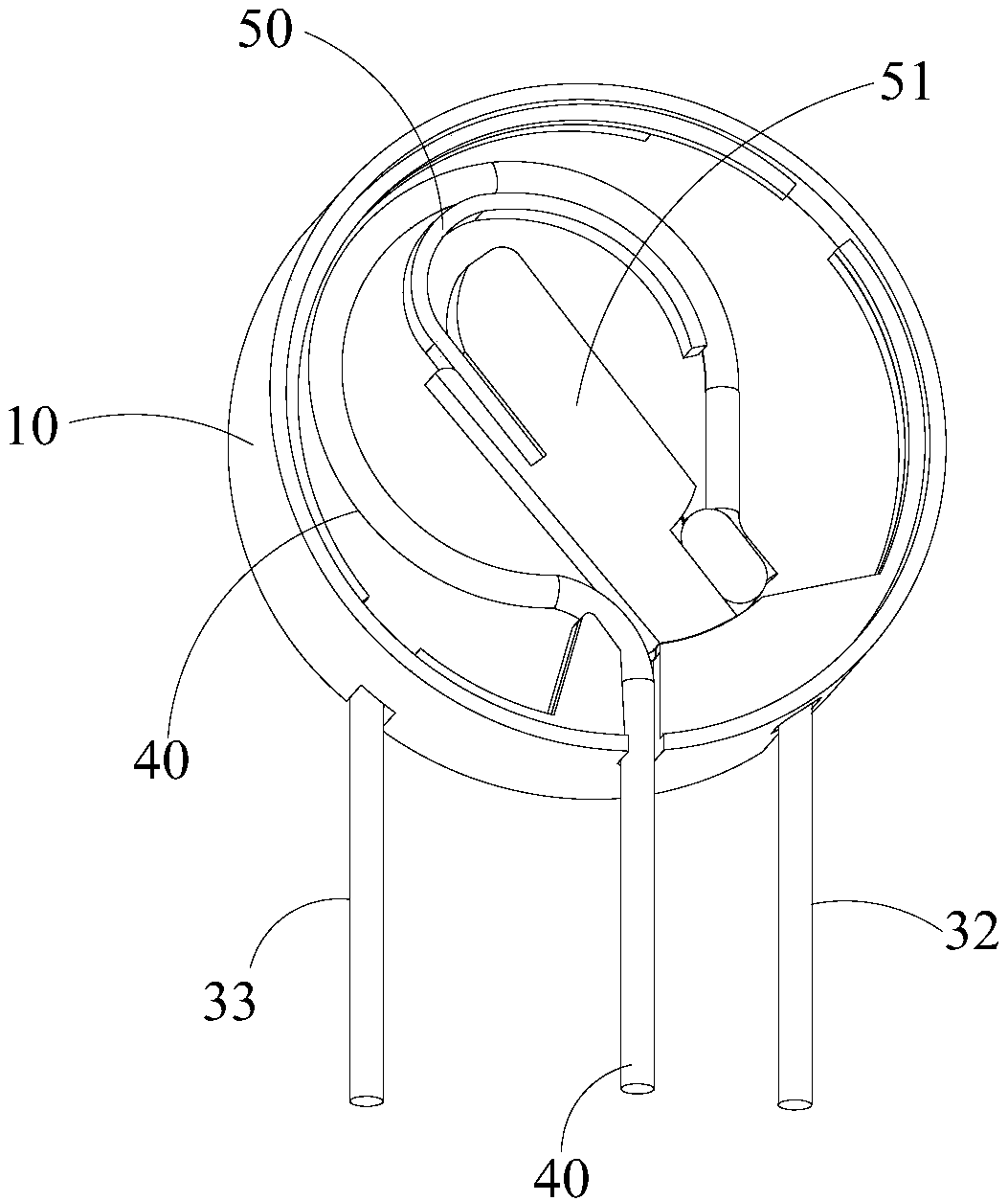

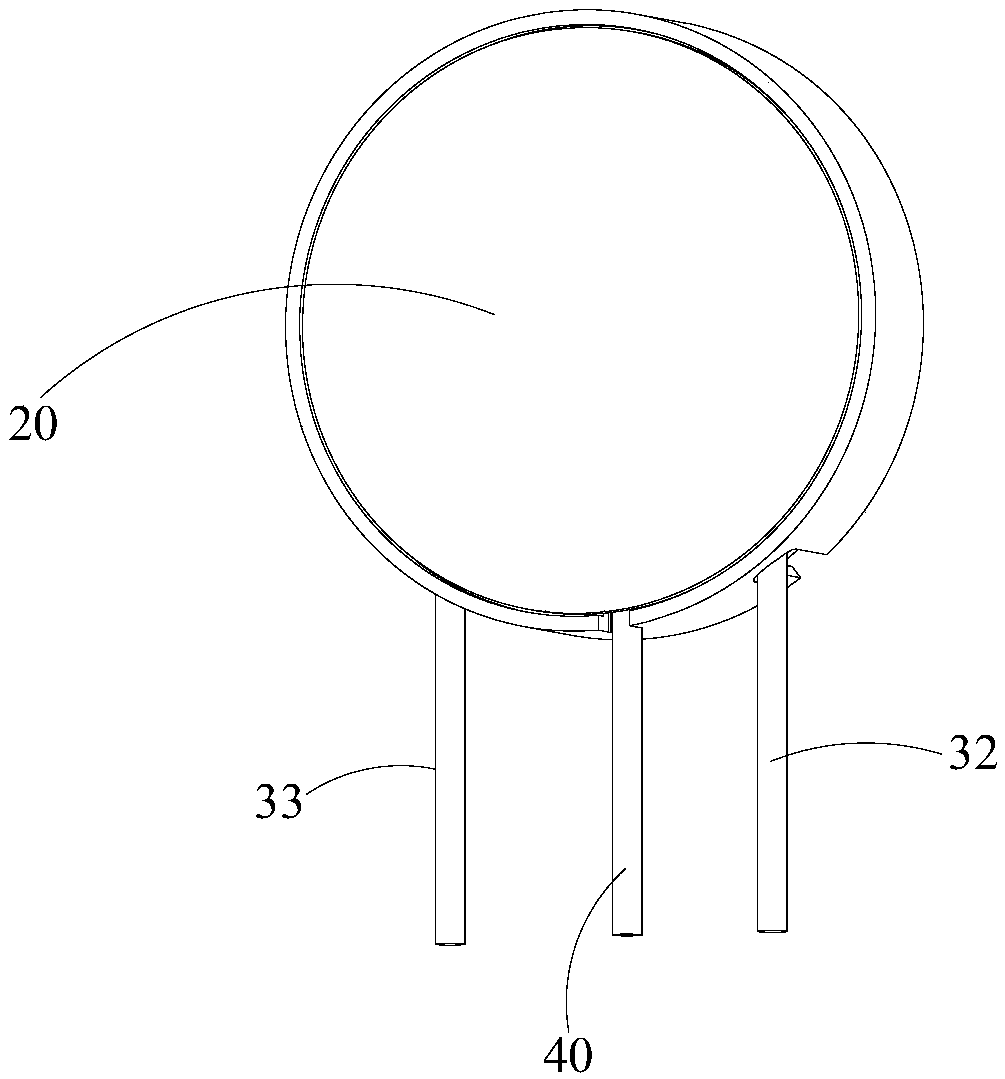

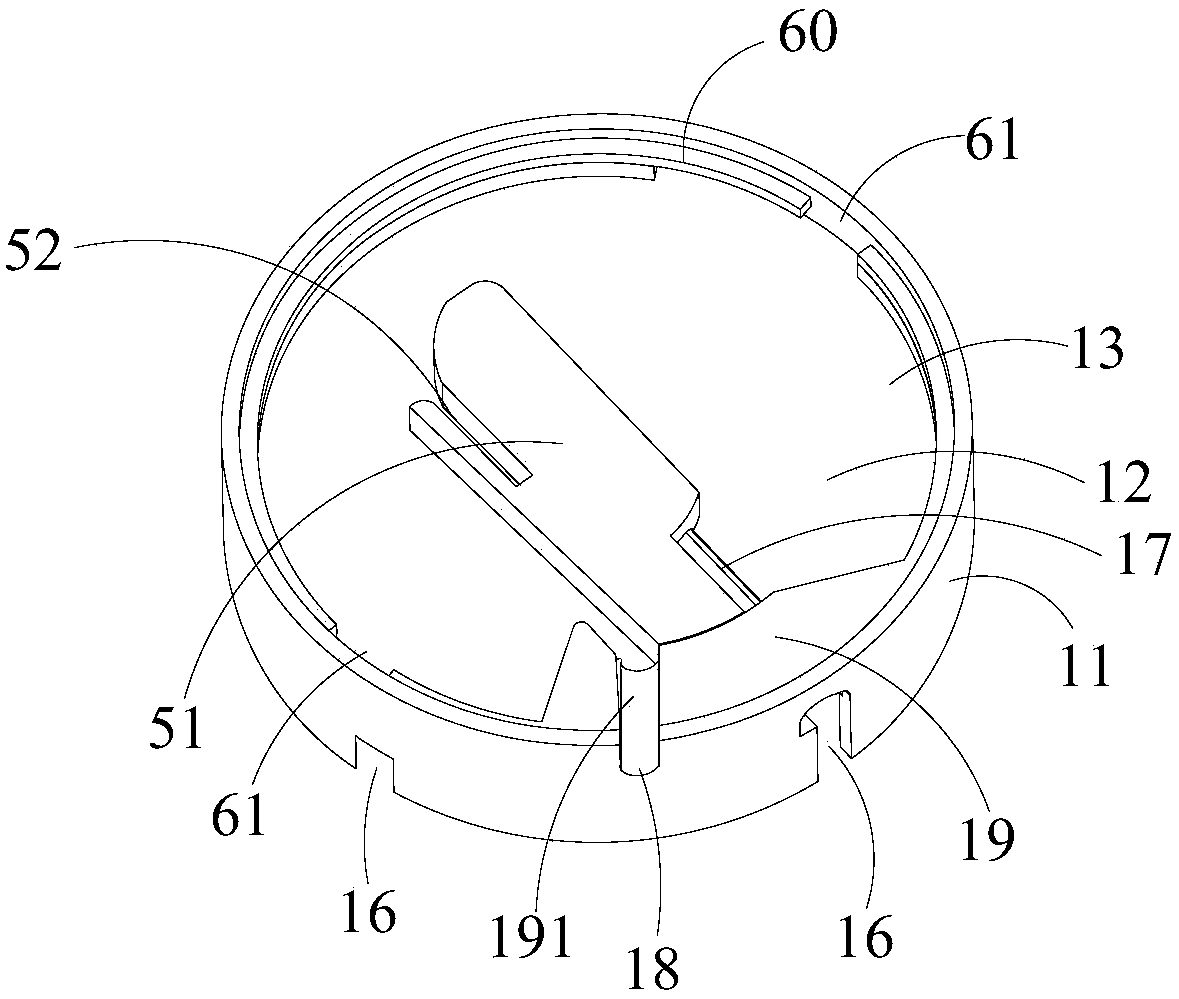

[0043] refer to Figure 1 to Figure 4 , in this embodiment, the base 10 is made of ceramics, which includes a cylindrical shell 11 and a bottom plate 12 placed in the shell 11, the bottom plate 12 divides the shell 11 into a first accommodating cavity 13 on the front side and a back side The second accommodating chamber 14 is provided with a top cover 20 on the upper cover of the first accommodating chamber 13 . The front side and the back side mentioned here refer to the side where the first accommodating cavity 13 of the base 10 is located as the front side, that is, the side where the top cover 20 is installed is the front side, and the opposite side is the back side. The front and back described below are the same as this reference direction and will not be repeated here. Wherein, a movable electrode 40 is disposed in the first accommodation chamber 13 , and a pressure-sensitive valve assembly 30 is disposed in the second accommodation chamber 14 .

[0044] refer to Fi...

Embodiment 2

[0055] refer to Figure 8 The difference between the small mechanical trip thermal protection varistor provided in the second embodiment of the present invention and the first embodiment is that the inner end of the movable electrode 40 is bent in a different shape. Correspondingly, the first receiving chamber 13 The fixed structure is also different. The movable electrode 40 is bent like a torsion spring. Specifically, the inner end of the movable electrode 40 is bent into a ring shape, and then the end extends to the window 17 to be welded and fixed to the exposed part of the first electrode 32 . A circular boss 70 is disposed inside the first receiving chamber 13 , and the ring-shaped bent portion is sheathed on the circular boss 70 . In this way, a double-coil torsion spring with better fatigue resistance is used as the movable electrode 40, which saves the auxiliary detachment shrapnel 60, reduces the number of parts and simplifies the installation process, which is cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com