Device for production of corrosion-resisting glass fiber-reinforced plastic pipe

A production device and FRP technology, applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of poor practicability, poor corrosion resistance of FRP pipes, poor corrosion resistance, unstable product quality, etc., to achieve good practicability, Simple structure and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

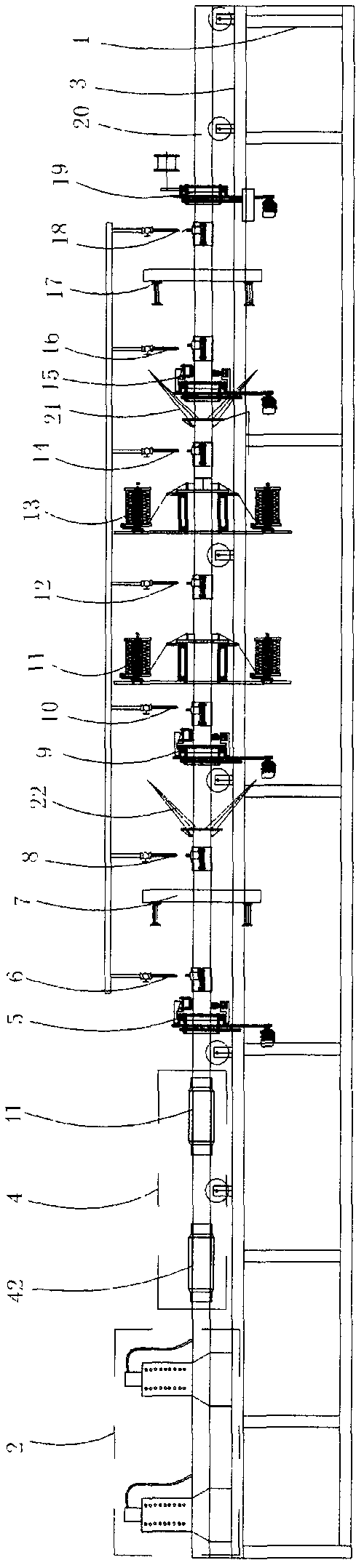

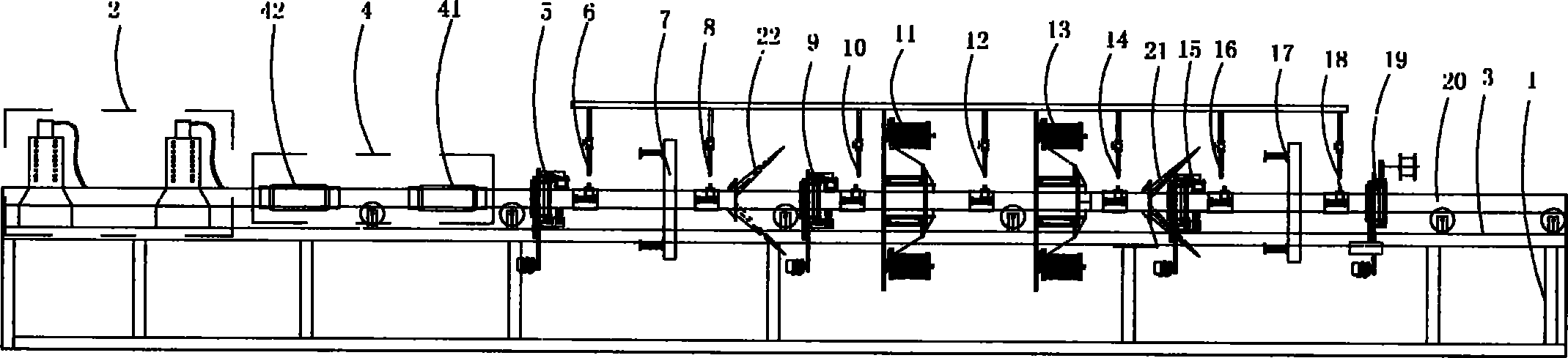

[0014] See figure 1 , a corrosion-resistant FRP pipeline production device, including a bracket 1, a traction device 2 arranged on the bracket 1, a transmission belt 3 rotationally connected with the traction device 2, and a cavity device 4 sequentially arranged on the transmission belt 3, The first glue brushing device 5, the first glue injection port 6, the first weaving device 7, the second glue injection port 8, the first straight yarn device 22, the second glue brushing device 9, the third glue injection port 10, the ring Left-handed yarn winding device 11, fourth glue injection port 12, circumferential yarn right-handed winding device 13, fifth glue injection port 14, straight yarn device 21, third glue brushing device 15, sixth glue injection port 16, The second weaving device 17, the seventh glue injection port 18 and the inner layer felting device 19 are provided with a mold core body 20 which is synchronized with the transmission belt 3 and moves in the same directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com