Manufacturing method of long-neck flange water-pressing sealing cover structure

A technology of a long-neck flange and a manufacturing method is applied in the manufacturing field of a long-neck flange water pressure sealing structure to achieve the effect of improving the level of manufacturing technology and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

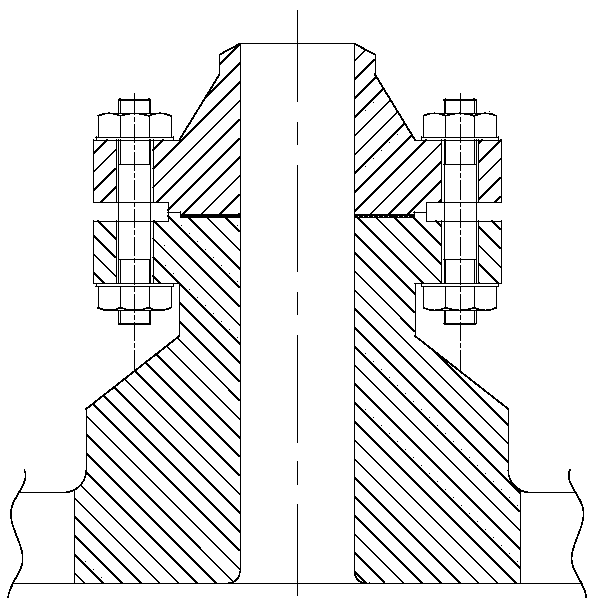

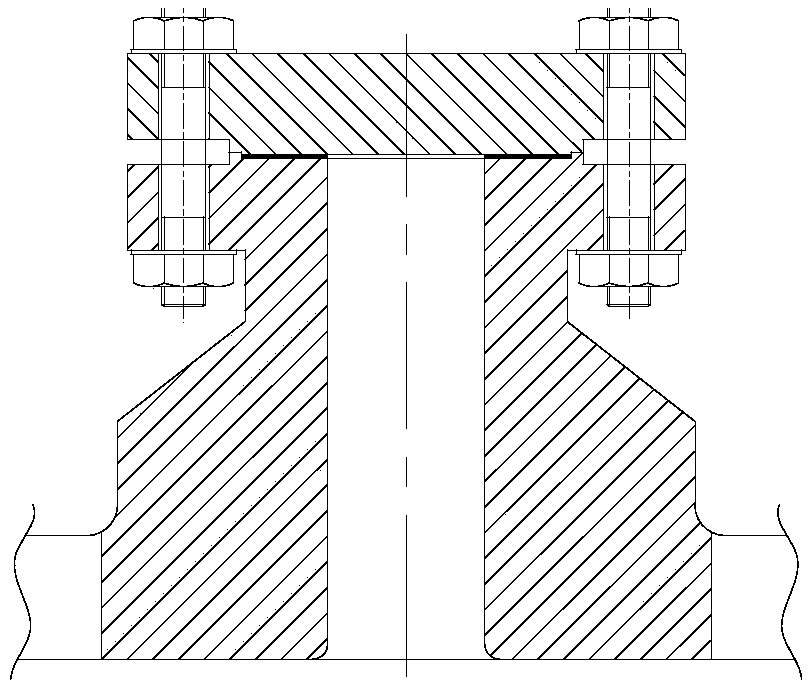

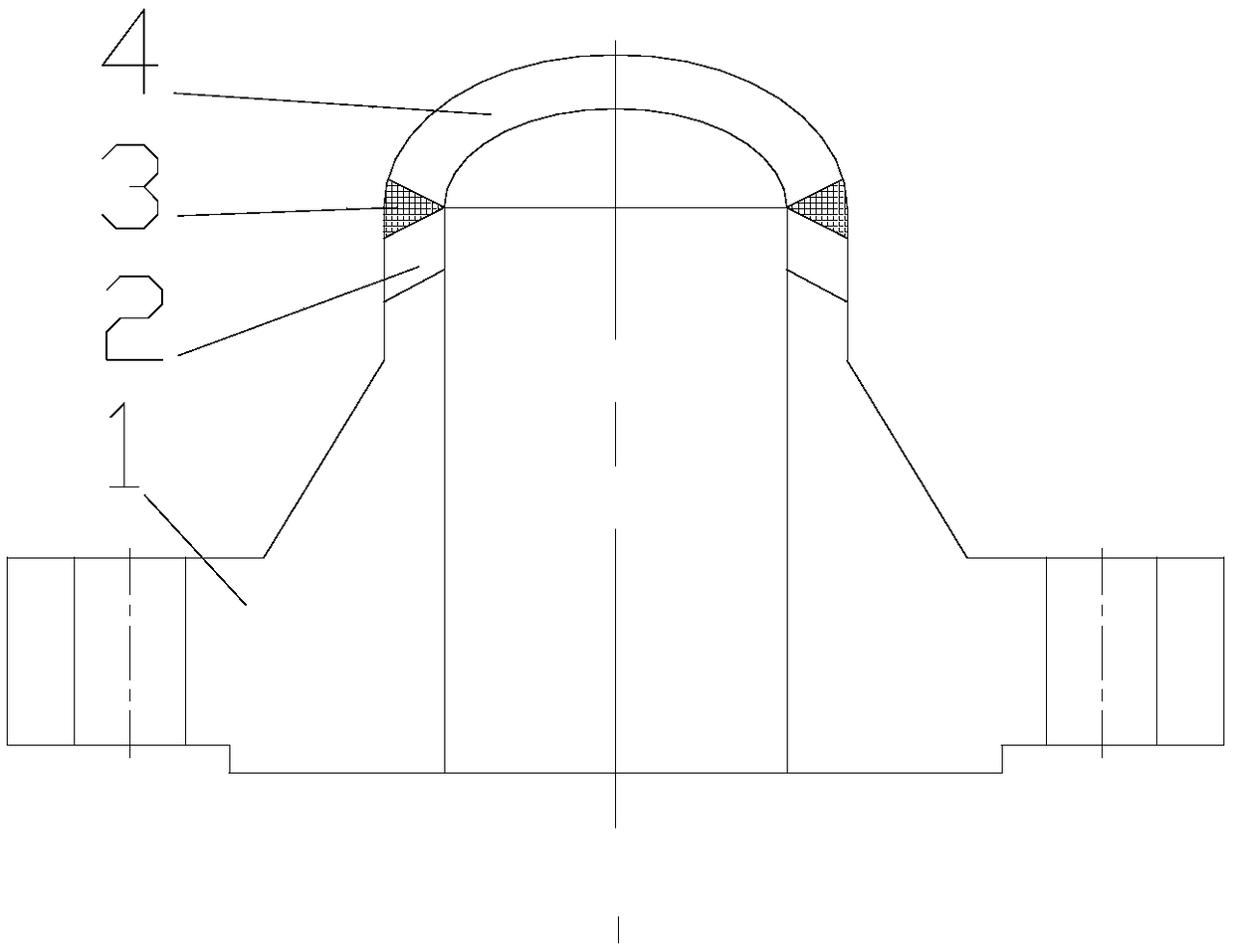

[0020] Such as Figure 3a , Figure 3b , Figure 3c As shown, the manufacturing method of a long-necked flange hydraulic sealing structure involved in this embodiment has the following steps:

[0021] 1. The long neck flange 1 forging is prepared, and the water pressure margin is reserved 2;

[0022] 2. Machining the long-necked flange 1 into shape, scribing and drilling holes on the lower flange surface of the long-necked flange 1, installing the welding end cap 4 on the upper end of the long-necked flange 1, and assembling with the equipment connecting flange;

[0023] 3. After the assembly is completed, the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com