Device and method for testing displacement adapting mechanisms of ship lifts

A technology of test device and adaptation mechanism, which is applied in the test of machine/structural components, the test of mechanical components, and the measurement device, etc., can solve the problems such as the test of the mechanism that cannot be adapted to the displacement of the ship lift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

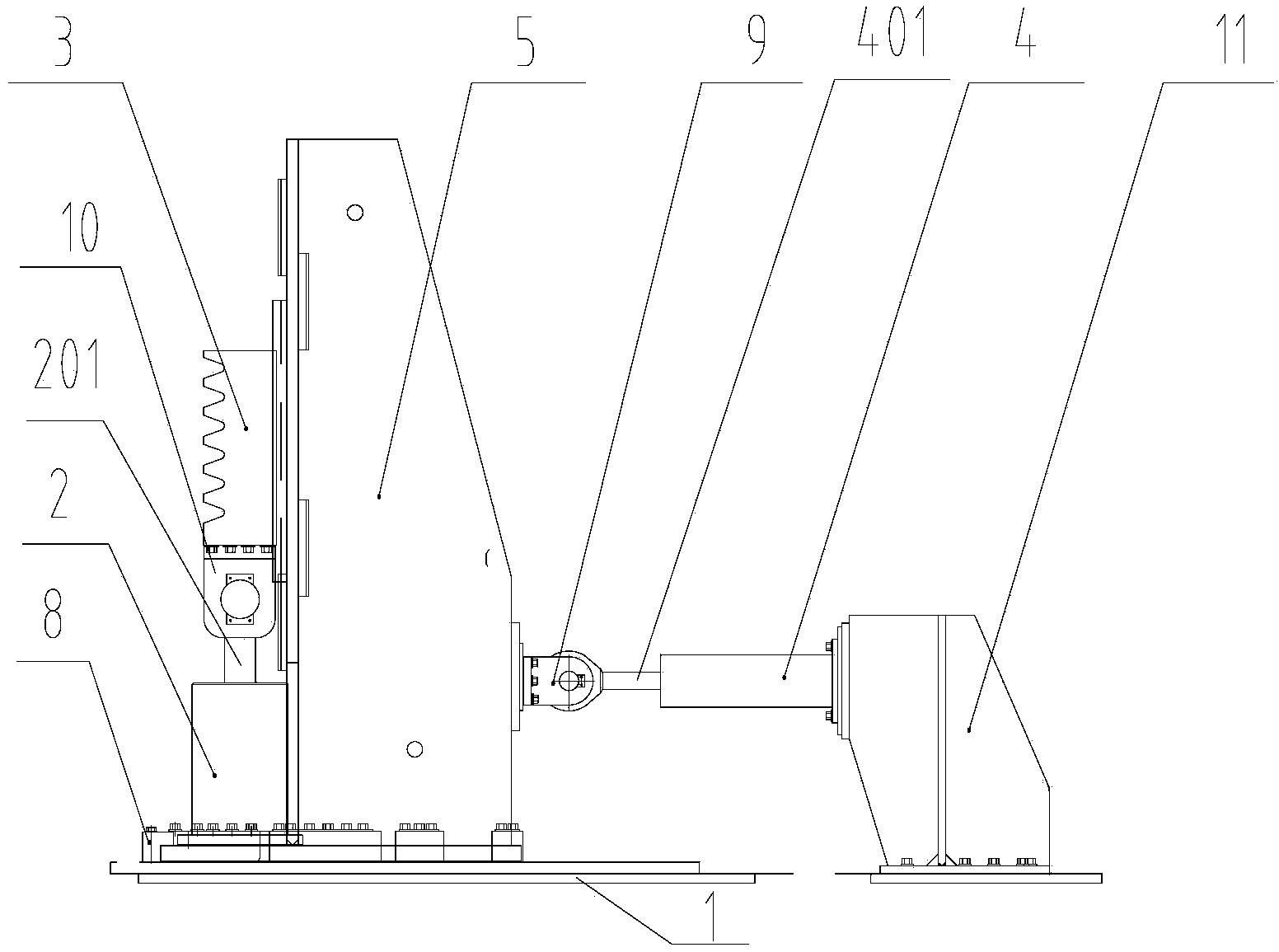

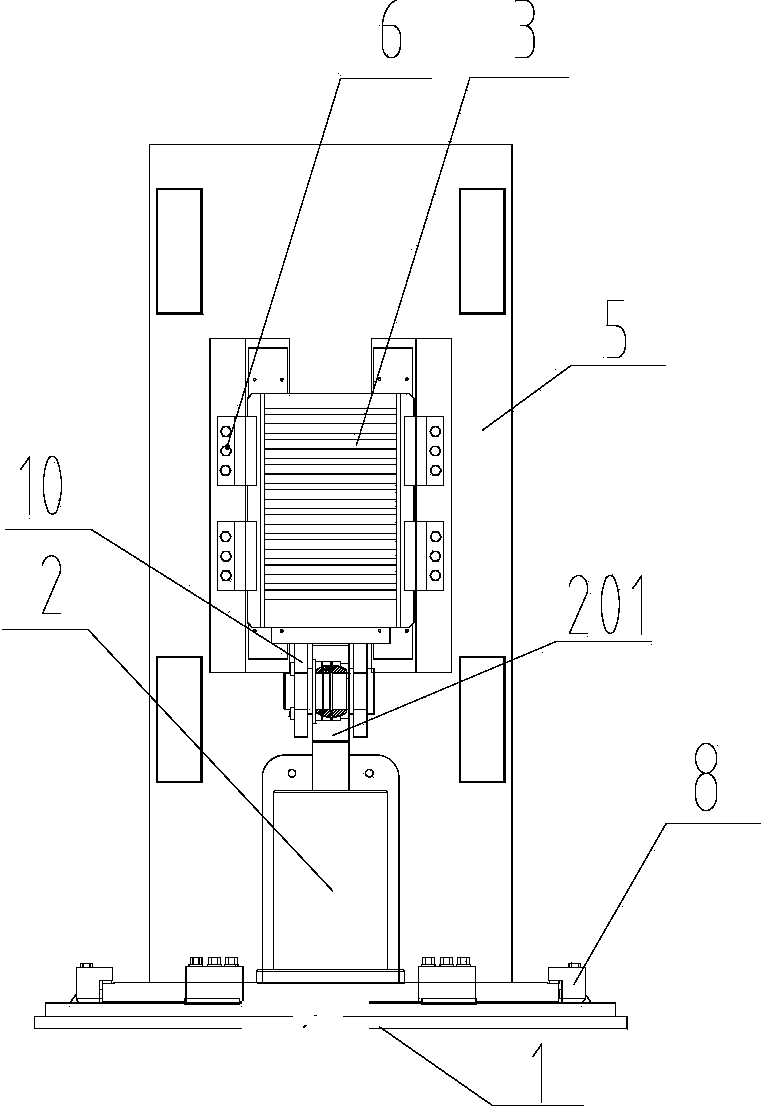

[0039] Embodiments of the present invention provide a test device for a displacement adaptation mechanism of a ship lift, such as figure 1 As shown, the test device includes: a support 1, a vertical oil cylinder 2 for providing vertical loading force, a tooling rack 3 with the same structure as the rack of the ship lift, and a horizontal oil cylinder 4 for providing horizontal loading force , the cylinder part of the horizontal oil cylinder 4 is installed on the support 1, the telescoping end 401 of the horizontal oil cylinder 4 is connected with the cylinder part of the vertical oil cylinder 2, and the cylinder part of the vertical oil cylinder 2 is slidably arranged on the support 1, and the vertical The telescopic end 201 of the straight oil cylinder 2 links to each other with the tooling rack 3, and the tooling rack 3 is arranged vertically. Since the rack of the displacement adaptation mechanism of the ship lift is very long, it cannot be used for the test. The rack of th...

Embodiment 2

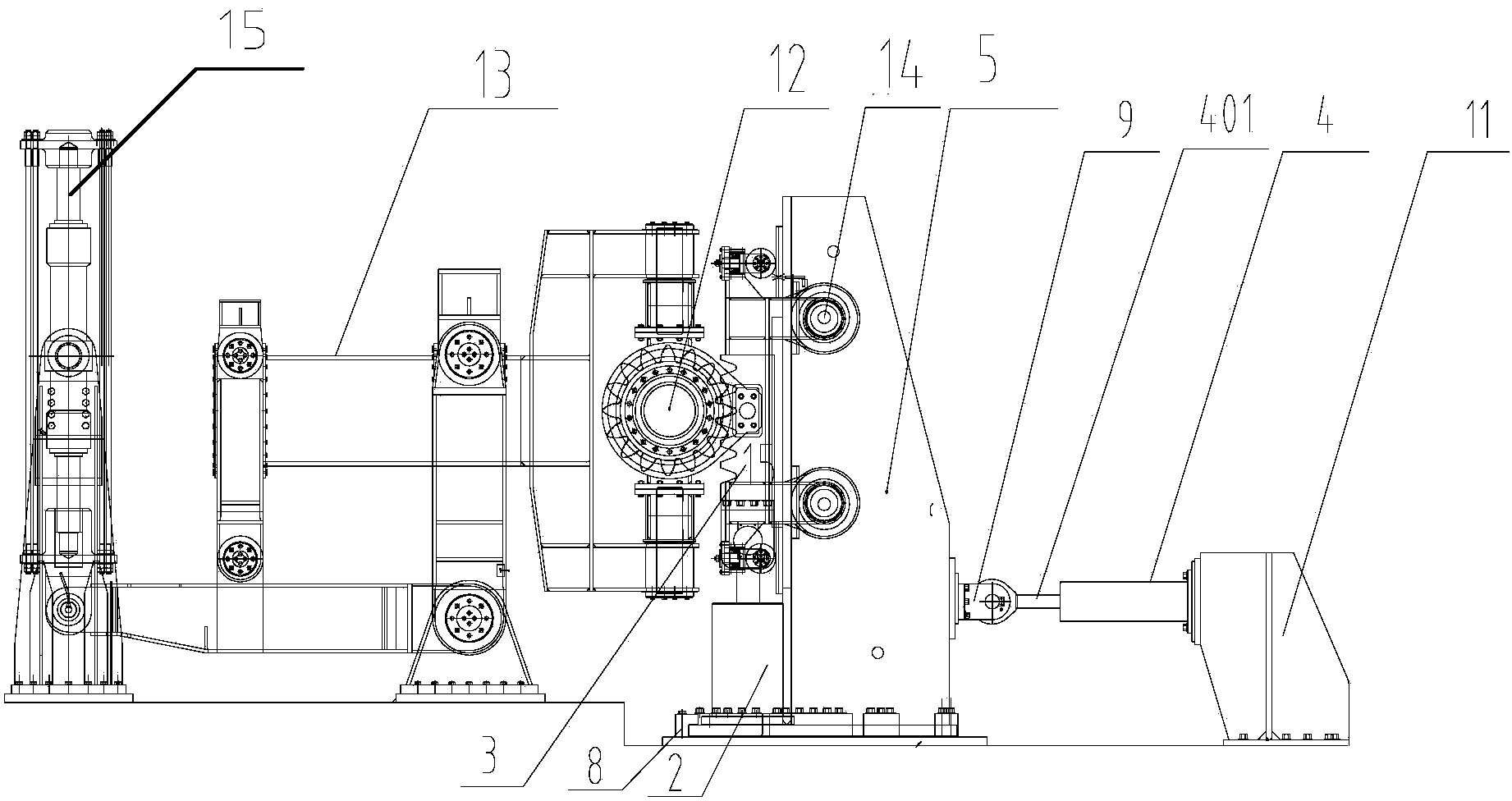

[0052] The invention provides a test method for the displacement adaptation mechanism of a ship lift, the test method comprising: a horizontal offset test method and a vertical offset test method, such as image 3 , Figure 4 with Figure 5 As shown, the horizontal offset test methods include:

[0053] A1: Install the pinion 12 on the four-link assembly 13, make the displacement adaptation mechanism of the ship lift in the normal working position, and install the pinion 12 on the tooling rack 3 through the supporting guide mechanism 14. Wherein, the normal working position of the displacement adapting mechanism of the ship lift is: the four-link assembly 13 of the displacement adapting mechanism of the ship lift is rectangular, and the horizontal bar is in a horizontal position; at the same time, the hydraulic spring component 15 of the displacement adapting mechanism of the ship lift and The position of the horizontal bar matches. Wherein, the structure of the pinion 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com