Insertion type pre-pressing valve

A pre-pressure valve and cartridge-type technology, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of poor pressure resistance, easy sticking of the valve core, large volume, etc., and achieve small volume, reliable operation, and communication strong streaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

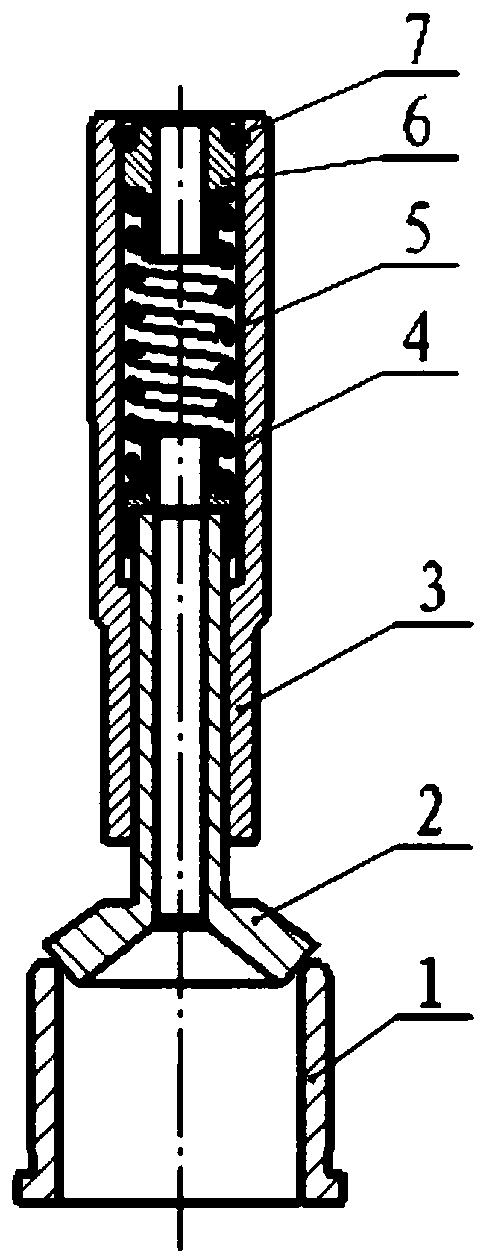

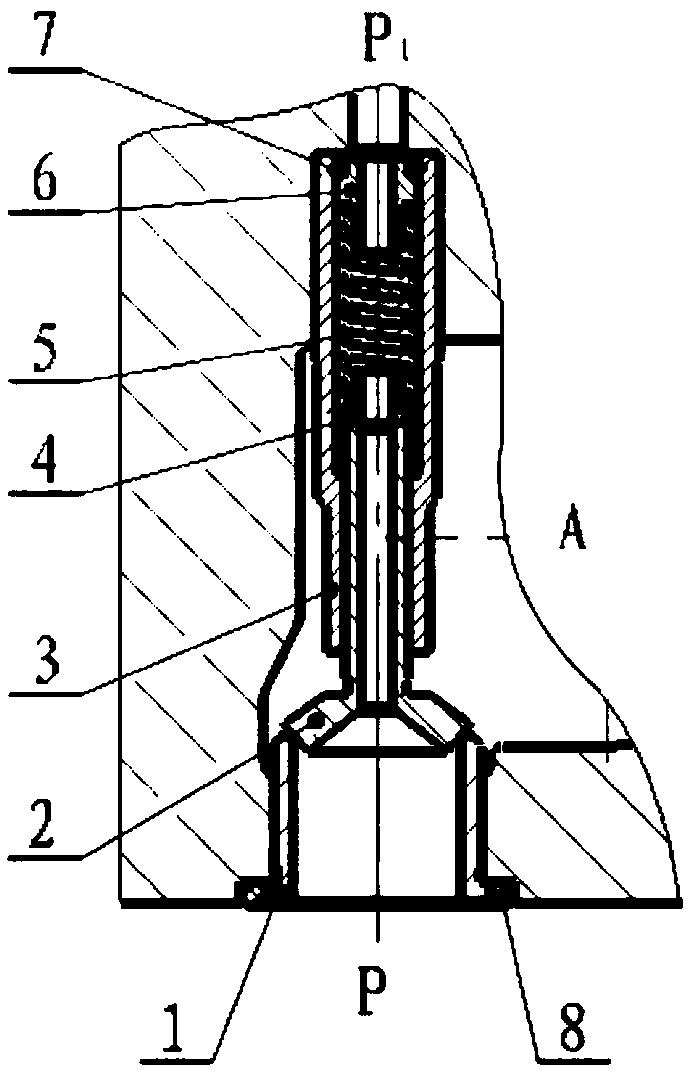

[0015] Such as figure 1 and figure 2 As shown, a cartridge preload valve in this embodiment includes a valve seat 1, a valve core 2, a guide sleeve 3, a first spring seat 4, a spring 5, a second spring seat 6 and a wire retaining ring 7 , the valve seat 1 is a hollow cylinder, the inner hole is a through hole with the same diameter, the upper edge of the inner hole of the valve seat 1 is kept sharp and cooperates with the taper surface of the valve core 2 to form a line seal to achieve oil sealing, the The lower end of the outer side of the valve seat 1 is provided with an outer circular step, so that it can be limited in the valve body; the valve core 2 is composed of a conical truncated cone and a hollow cylindrical guide rod, and the hollow cylindrical guide rod is arranged at the center of the top surface of the conical truncated The hollow hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com