Manufacturing method of vertical organic thin film transistor

A technology of organic thin film and production method, which is applied in the fields of semiconductor/solid-state device manufacturing, temperature recording method, electric solid-state device, etc. The effect of overcoming high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The description of the present invention provides different examples to illustrate the technical features of different implementations of the present invention. Wherein, the configuration of each component in the embodiment is for clearly illustrating the content disclosed in the present invention, and is not intended to limit the present invention. In addition, part of the reference numerals in the figures in different embodiments is repeated for the purpose of simplifying the description, and does not imply the correlation between different embodiments.

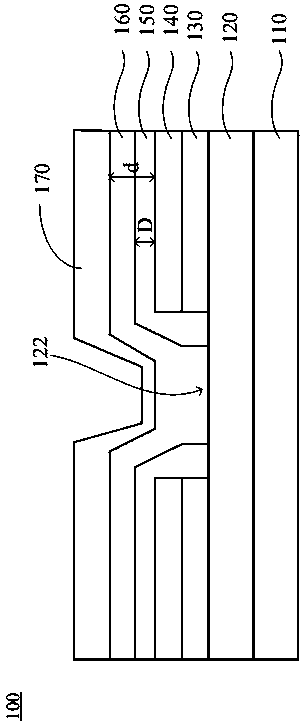

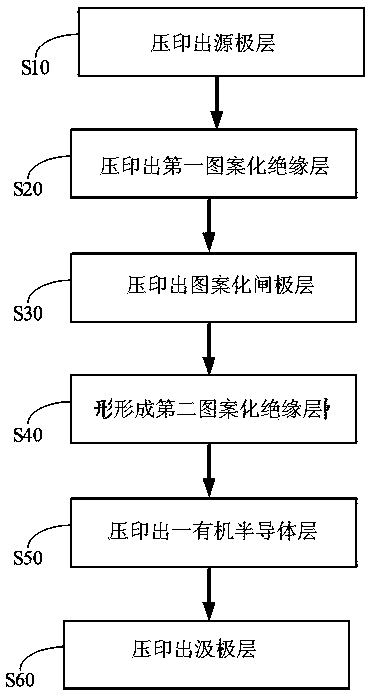

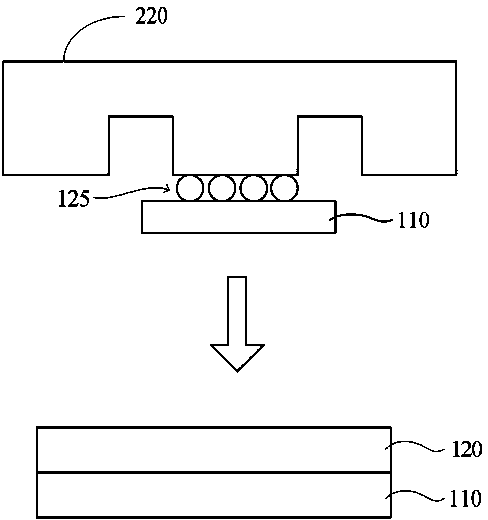

[0037] Please refer to figure 1 , figure 1 The vertical organic thin film transistor of the preferred embodiment of the present invention is shown, and it should be noted that it is not shown in actual scale. The vertical organic thin film transistor 100 includes a substrate 110, a source layer 120, a first patterned insulating layer 130, a patterned gate layer 140, a second patterned insulating layer 150, an organ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com