Upper casing of portable computer of magnalium material and plastic and preparation thereof

A magnesium-aluminum alloy and laptop computer technology, applied in chemical instruments and methods, metal layered products, lamination auxiliary operations, etc., can solve the problems of compression resistance, poor impact resistance, poor strength, easy deformation, etc. Strong impact, solve the effect of affecting wireless operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

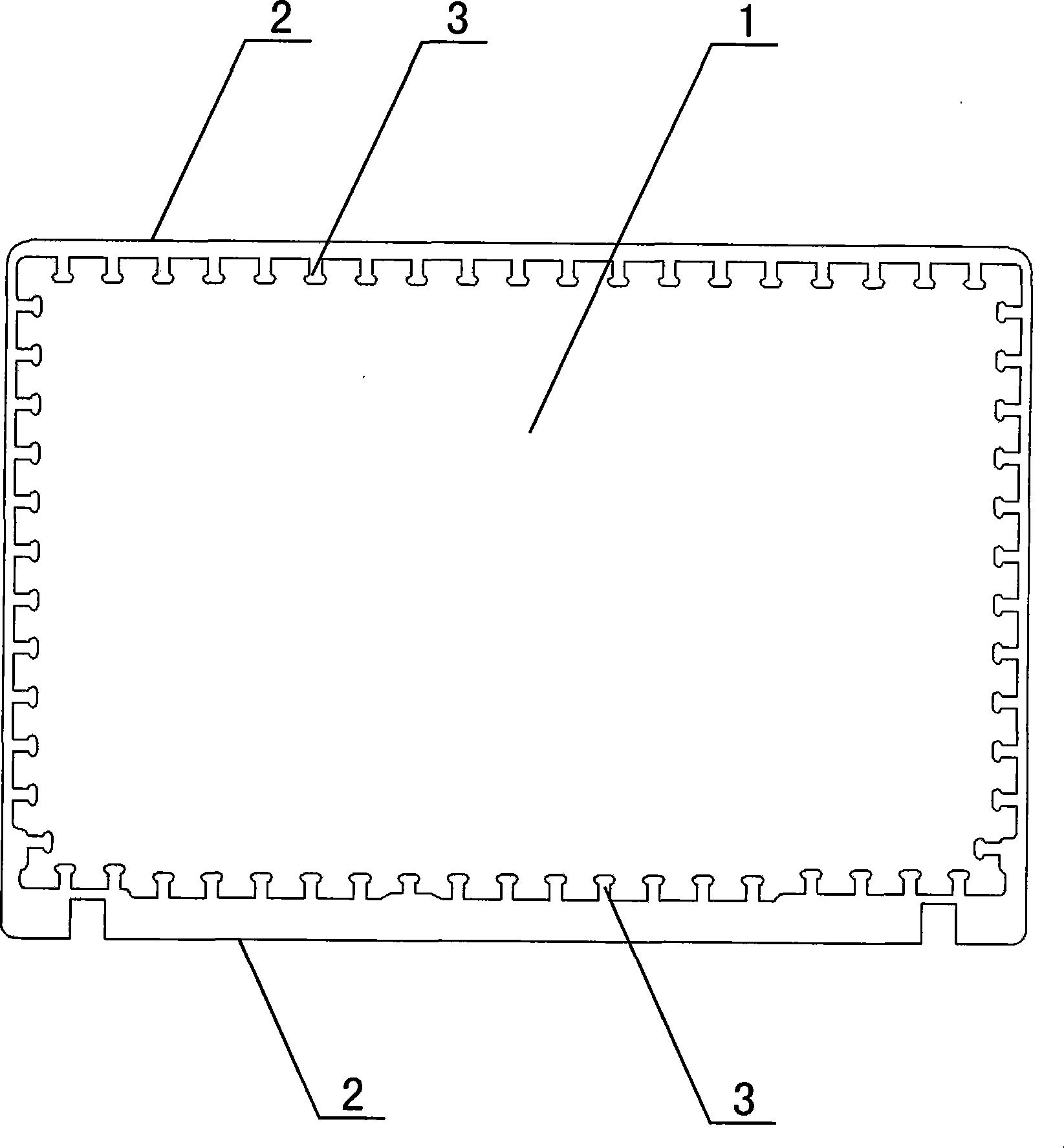

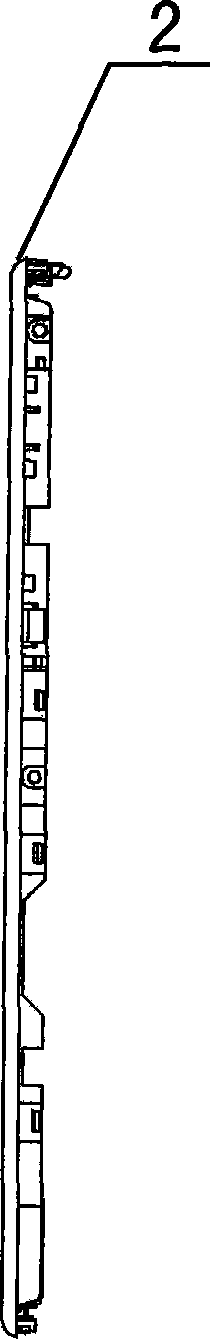

[0018] Select high-quality magnesium-aluminum alloy materials, according to the shape and specification of the upper shell of the laptop computer case, die-cast a magnesium-aluminum alloy plate 1 with a thickness of 0.8 mm and crown-shaped edges around it. The above-mentioned magnesium-aluminum alloy plate 1 is placed in the mold of the upper shell of the laptop computer casing, and injected by a hot-press injection molding machine, so that the periphery 3 of the magnesium-aluminum alloy plate 1 is firmly combined with the plastic 2 to become a semi-finished product. The above-mentioned semi-finished product that firmly combines the periphery 3 of the injection-molded magnesium-aluminum alloy plate 1 with the plastic 2 is carefully polished and surface-decorated to make the upper shell of a laptop computer case that combines the magnesium-aluminum alloy plate and plastic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com