Notebook computer enclosure and manufacturing method thereof

A technology of notebook computers and production methods, which is applied in the direction of electrical digital data processing, instruments, digital data processing parts, etc., can solve the problems of poor compression resistance, insufficient rigidity, insufficient strength, etc., and achieve the goal of not being easily damaged and reducing the impact of shrinkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

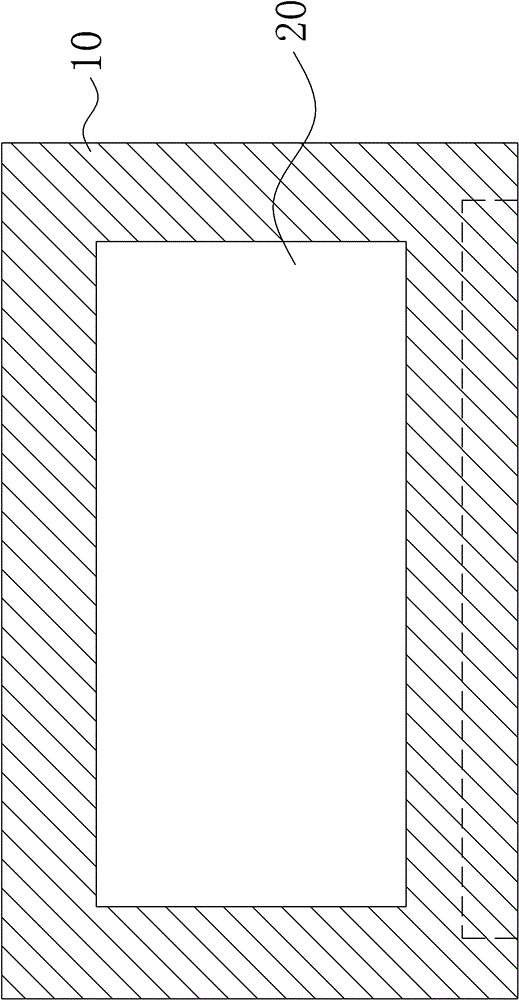

[0033] Step 101: According to the shape and specifications of the notebook computer shell, prepare an aluminum alloy shell and perform sanding treatment, and its thickness is 0.6mm.

[0034] Step 102: Arranging a glue layer by dispensing glue at the position where the periphery of the inner surface of the aluminum alloy casing is combined with the plastic frame.

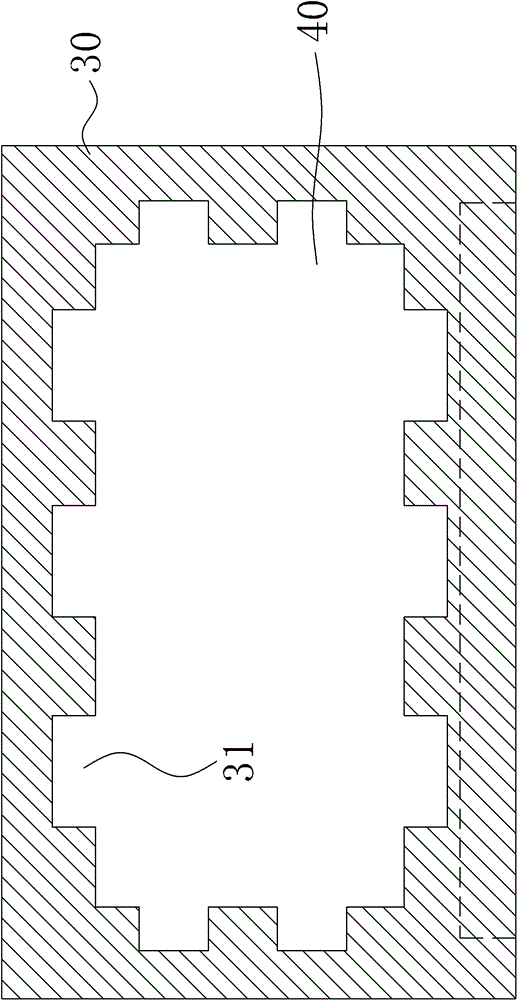

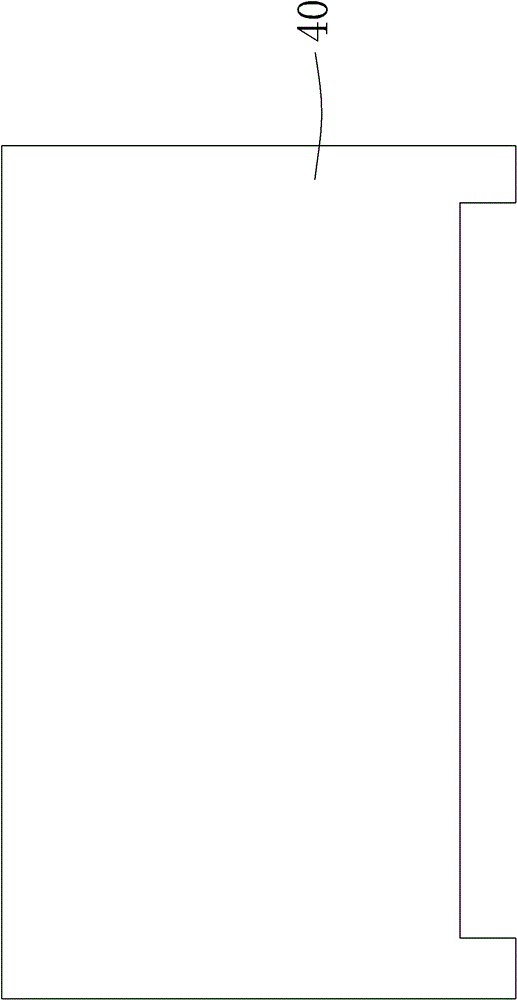

[0035] Step 103: Put the aluminum alloy shell with adhesive layer into an injection mold, and inject PA+50% GF engineering plastic into a plastic frame by RHCM process and combine it with the periphery of the inner surface of the aluminum alloy shell. Several concave notches are uniformly arranged on the frame, and the injection thickness of the plastic frame is 1.0mm.

[0036] After the notebook computer casing obtained in the above steps is polished, filled with soil, and sprayed, a finished notebook computer casing with a seamless appearance can be obtained.

Embodiment 2

[0038] Step 201: According to the shape and specifications of the notebook computer shell, prepare a magnesium alloy shell and perform hairline treatment, and its thickness is 0.8mm.

[0039] Step 202: Arranging a glue layer by spraying glue at the position where the inner surface of the magnesium alloy housing is combined with the plastic frame.

[0040] Step 203: Put the magnesium alloy shell with adhesive layer into an injection mold, inject PPS+30%GF engineering plastic into a plastic frame by RHCM process and combine it with the periphery of the inner surface of the magnesium alloy shell, the plastic Several concave notches are uniformly arranged on the frame, and the injection thickness of the plastic frame is 1.2mm.

[0041] After the semi-finished notebook computer case obtained in the above steps is polished, filled with soil and sprayed, a finished notebook computer case with a seamless appearance can be obtained.

Embodiment 3

[0043] Step 301: According to the shape and specifications of the notebook computer shell, prepare a stainless steel shell and perform mirror treatment, the thickness of which is 1.0mm.

[0044] Step 302: At the position where the inner surface of the stainless steel shell is combined with the plastic frame, arrange a glue layer by applying glue.

[0045] Step 303: Put the stainless steel shell with the adhesive layer into an injection mold, inject PPS+30%GF engineering plastics into a plastic frame through the RHCM process, and combine it with the periphery of the inner surface of the stainless steel shell, on the plastic frame Several concave notches are evenly arranged, and the injection thickness of the plastic frame is 1.4mm.

[0046] After the semi-finished notebook computer case obtained in the above steps is polished, filled with soil and sprayed, a finished notebook computer case with a seamless appearance can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com