Single-core two-way plastic optical fiber system and plastic optical fiber connectors

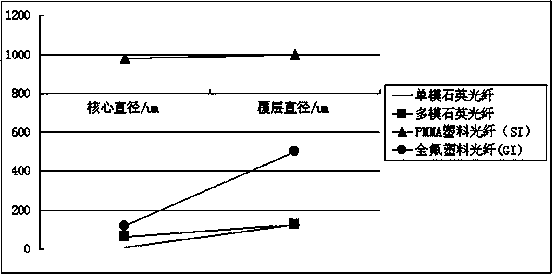

A plastic optical fiber system, plastic optical fiber technology, applied in cladding optical fiber, optical waveguide light guide, light guide, etc., can solve the problems of short transmission distance of SI type plastic optical fiber, inability to use optical fiber connectors, and difficulty in installation and maintenance of quartz optical fiber. , to achieve the effect of promoting popularization, low power consumption, and improving the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: A single-core bidirectional plastic optical fiber system implementation scheme.

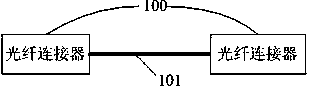

[0039] The single-core bidirectional plastic optical fiber system provided by the present invention is such as figure 1 As shown, it contains a perfluoroplastic optical fiber 101 and two plastic optical fiber connectors 100. The plastic optical fiber connector 100 is tightly fixed on both ends of the plastic optical fiber. The plastic optical fiber is connected with the optical fiber through the ferrule in the plastic optical fiber connector 100. Interface device. The perfluoroplastic optical fiber 101 selected in this embodiment belongs to a type of GI plastic optical fiber, and other GI plastic optical fibers can also be used in specific implementation.

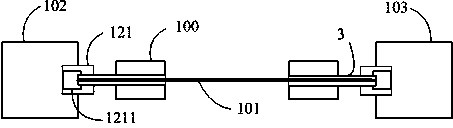

[0040] figure 2 Shown is an application environment of a single-core bidirectional plastic optical fiber system, including two plastic optical fiber connectors 100, a perfluoroplastic optical fiber 101, and devices 102 and 103 wi...

Embodiment 2

[0054] Embodiment 2: An SC type plastic optical fiber connector.

[0055] The plastic optical fiber connector provided in this embodiment is an SC-type plastic optical fiber connector, as shown in Figure 5 (a) and Figure 5 (b). The main components are the extension cover 11, the ferrule 12, the spring 13, and the ferrule. The outer cover 14 and the sleeve 15 also include the SC cover 16 and the tail pipe 17. The SC cover 16 is provided with a plug-in switch, which can be used for positioning and limiting the relative position between the plastic optical fiber connector and the mating component. The ferrule 13 has a hollow structure with an outer diameter of 2.5mm and an inner hole diameter of 1.0mm, which ensures the convenience of inserting the perfluoroplastic optical fiber with an outer diameter of 0.5mm into the plastic optical fiber connector. The difference between the outer diameter of the plastic optical fiber and the inner aperture of the ferrule is too large, which ma...

Embodiment 3

[0077] Embodiment 3: An LC type plastic optical fiber connector.

[0078] The LC type plastic optical fiber connector provided by this embodiment, as shown in Figures 6(a) and 6(b), includes a protective cap 21, an LC shell 22, a spring 23, a ferrule 24, a ferrule cover 25, and a sleeve 26 and tail pipe 27. The ferrule 24 is a hollow structure, made of metal or plastic, with an outer diameter value of 1.25mm and an inner hole diameter of 1.0mm, which ensures the convenience of inserting a 0.5mm outer diameter perfluoroplastic optical fiber into a plastic optical fiber connector. At the same time, the difference between the outer diameter of the perfluoroplastic optical fiber and the inner aperture of the ferrule is not too large, which makes the connection between the plastic optical fiber connector and the perfluoroplastic optical fiber unstable.

[0079] Figure 6 (a) shows the assembly sequence of the LC-type plastic optical fiber connector, as follows:

[0080] Use scissors to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com