Processing method of phc communication antenna

The technology of a communication antenna and a processing method is applied in the processing field of processing the PHC communication antenna, which can solve the problems of high labor intensity, high investment cost, troublesome antenna bracket, etc., and achieve the effects of reducing labor, low input cost and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

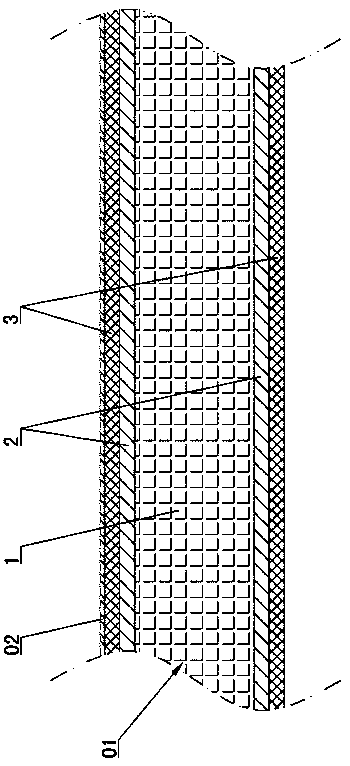

[0020] The present invention relates to a PHC communication antenna, such as figure 1 As shown, the PHC composite sheet 01 and the aluminum mesh 02 are included. The PHC composite sheet includes a honeycomb paper core 1. The upper and lower sides of the honeycomb paper core 1 are each pasted with glass fiber mat 2, and then on the upper, The surface of the glass fiber mat 2 on the lower two sides is sprayed with a PU material layer 3, and the aluminum mesh 02 is tightly combined with the PU material layer 3 on one side. In the actual product, the PU material layer 3 on one side is melt-coated on the surface of the aluminum mesh 02.

[0021] The PHC communication antenna of the present invention is first processed into PU composite sheet 01 from PU, glass fiber and honeycomb paper core, and then the PU composite sheet 01 is placed in a heating mold and molded together with aluminum mesh 02. The product has a light weight , The specific gravity is only 1.25, the strength is high, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com