High-speed automatic soft trademark cutting machine

A cutting machine and automatic technology, which is applied in metal processing and other directions, can solve the problems of high cutting precision and packaging quality, and achieve the effects of ensuring cutting effect and product quality, improving utilization rate and extending life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

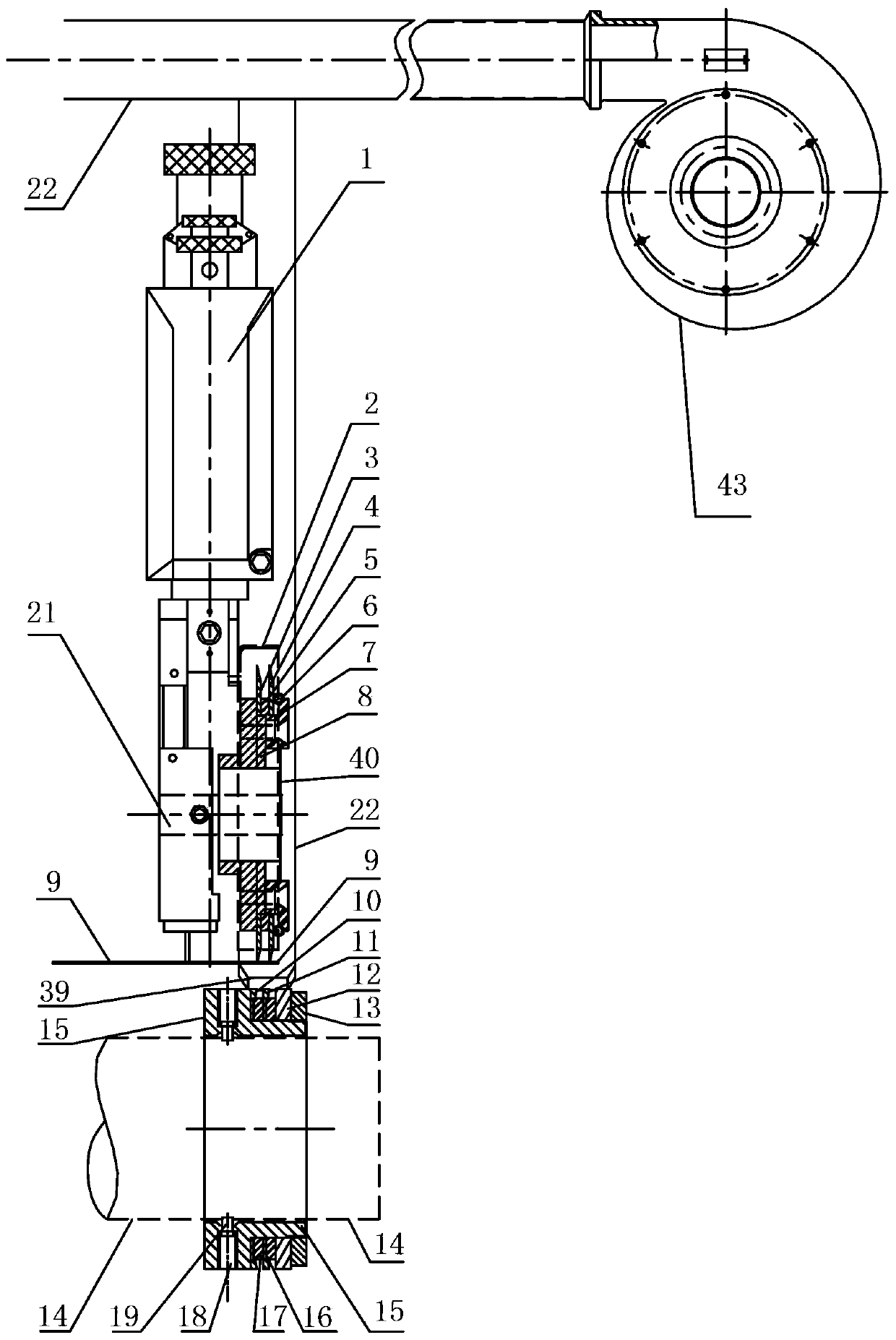

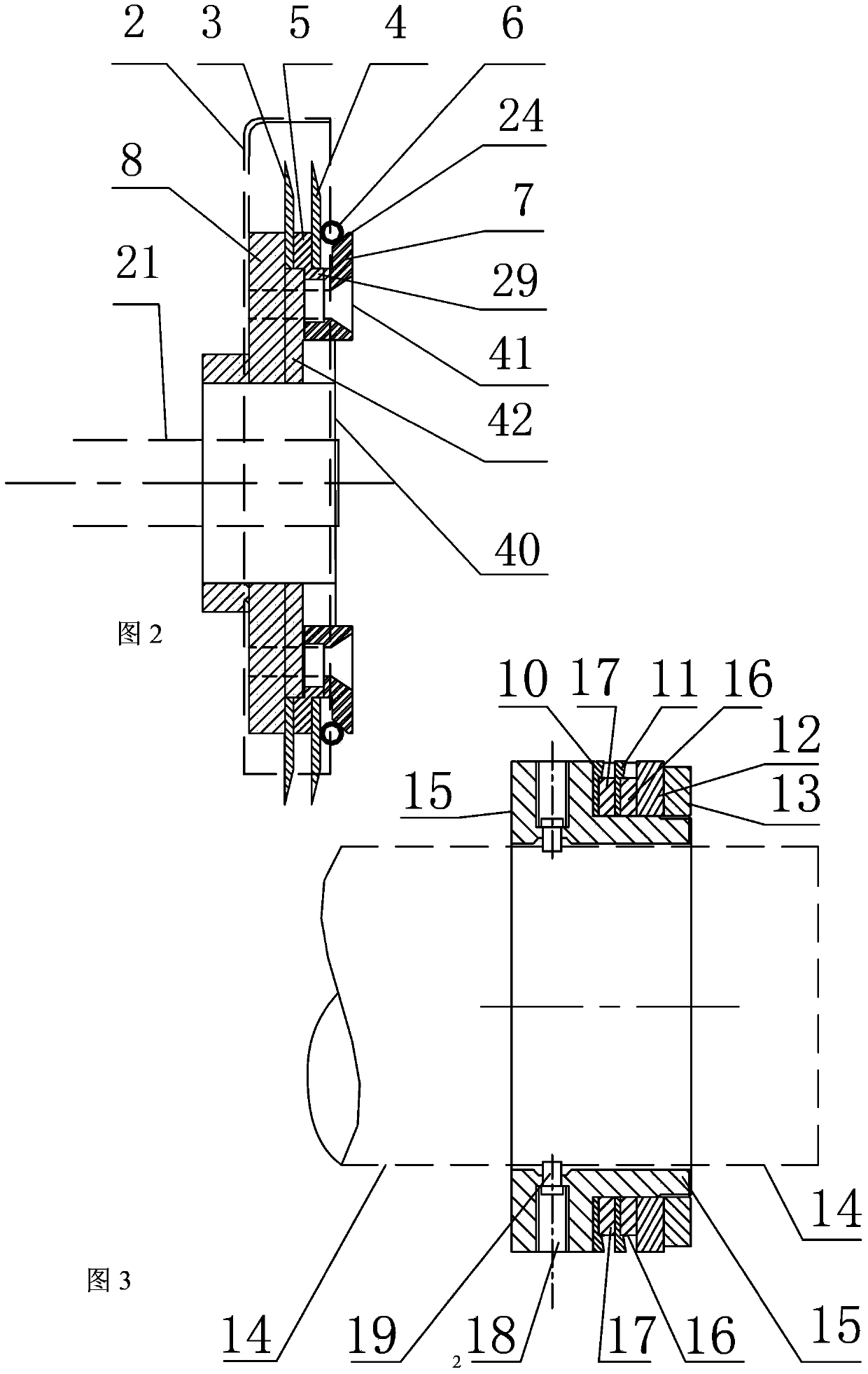

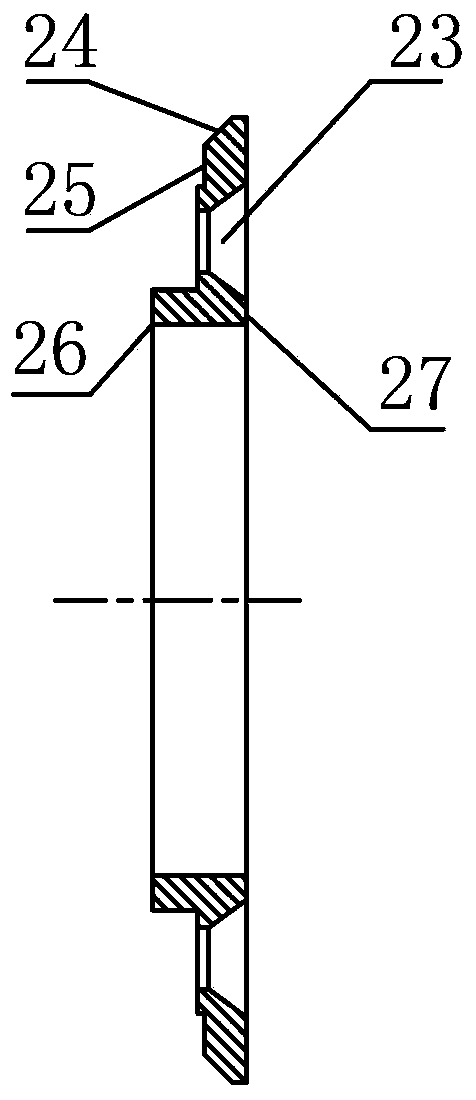

[0032]Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 As shown in , the high-speed automatic soft label cutting machine is used for high-speed cutting of precision printed parts, including an upper knife assembly, a bottom knife assembly, and a waste removal device that are separately set; the upper knife assembly includes the same The printing machine frame is fixed and the lower knife cylinder 1 with the piston rod moving direction vertically is connected with the piston rod of the lower knife cylinder and the combined knife cylinder 21 with the piston rod moving direction horizontally set is connected with the piston rod of the combined knife cylinder The cutting knife is provided with an annular upper knife rest 8, and the upper knife rest 8 is installed on the piston rod of the combined knife cylinder 21 through a bearing 40. The lower knife cylinder stretches out the piston rod when the cutting machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com