Lignite complete cycle high-efficiency dry distillation quality improving system and method

A full cycle, dry distillation technology, applied in special forms of dry distillation, direct heating dry distillation, gas dust removal, etc., can solve the problems of large gas flow resistance and low thermal efficiency, achieve sufficient heat exchange, high thermal efficiency, and solve the effects of low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

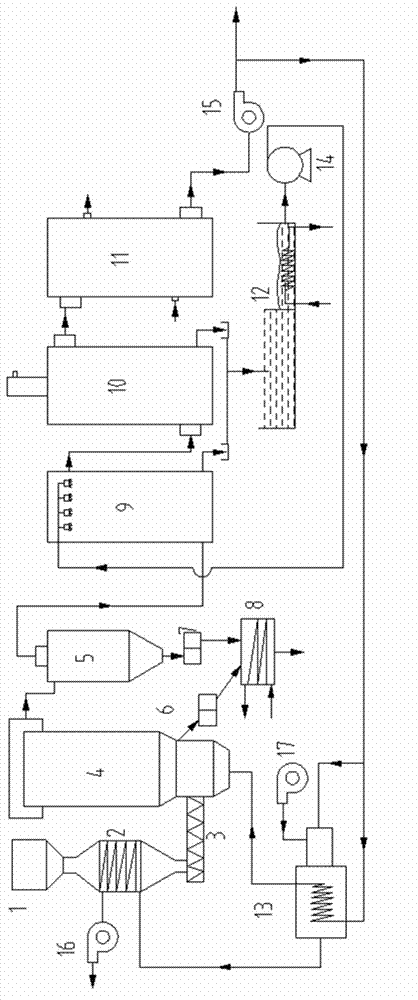

[0040] The invention discloses a method for high-efficiency carbonization and upgrading of pulverized lignite in a full cycle. The powdered lignite is dried in a vertical drying furnace and then enters the fluidized carbonization furnace. The temperature of the hot gas fed into the bottom of the fluidized carbonization furnace is 520 ° C. In the case of isolation from the air, the lignite powder and the hot gas are flowed in contact with each other. Most of the coke powder from the dry distillation stays in the fluidized dry distillation furnace and is discharged from the overflow port. The hot gas with tar and a small amount of coke powder flows into the cyclone dust collector, and the coke powder separated by the cyclone dust collector and the coke powder output from the fluidized carbonization furnace are converged and sent to the gas-solid heat exchanger, and become coke powder products after cooling down. The gas flowing out from the outlet of the cyclone dust collector p...

Embodiment 2

[0042]The invention discloses a method for high-efficiency carbonization and upgrading of pulverized lignite in a full cycle. The powdered lignite is dried in a vertical drying furnace and then enters the fluidized carbonization furnace. The temperature of the hot gas fed into the bottom of the fluidized carbonization furnace is 550 °C. In the case of air isolation, the lignite powder and the hot gas are flowed in contact with each other. Most of the coke powder from the dry distillation stays in the fluidized dry distillation furnace and is discharged from the overflow port. The hot gas with tar and a small amount of coke powder flows into the cyclone dust collector, and the coke powder separated by the cyclone dust collector and the coke powder output from the fluidized carbonization furnace are converged and sent to the gas-solid heat exchanger, and become coke powder products after cooling down. The gas flowing out from the outlet of the cyclone dust collector passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com