Special evaporator for heat-pipe refrigerating hybrid air-conditioner

A composite air conditioner and evaporator technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve problems such as resistance, reduce resistance, improve heat dissipation and stability, and maintain smooth flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

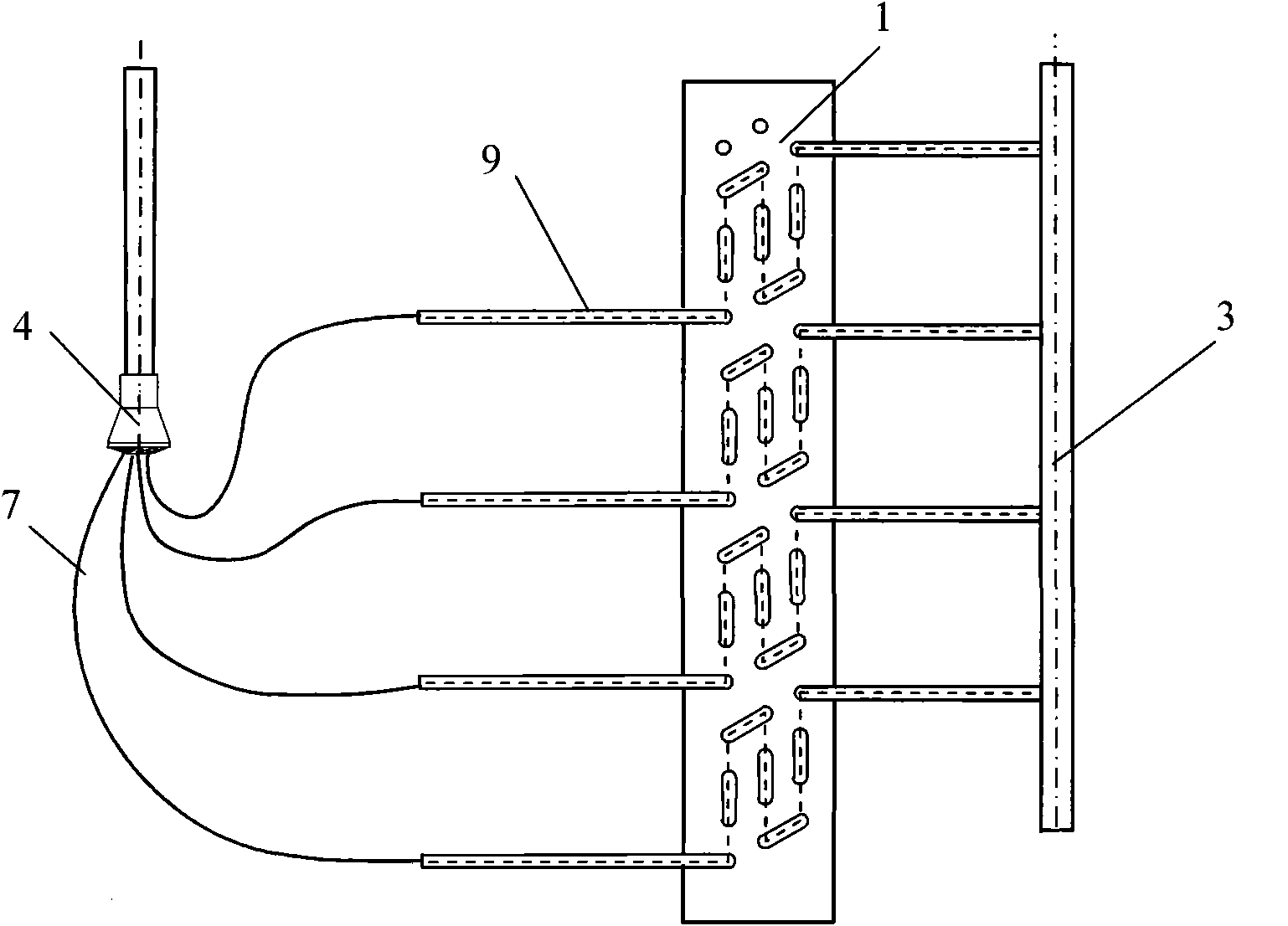

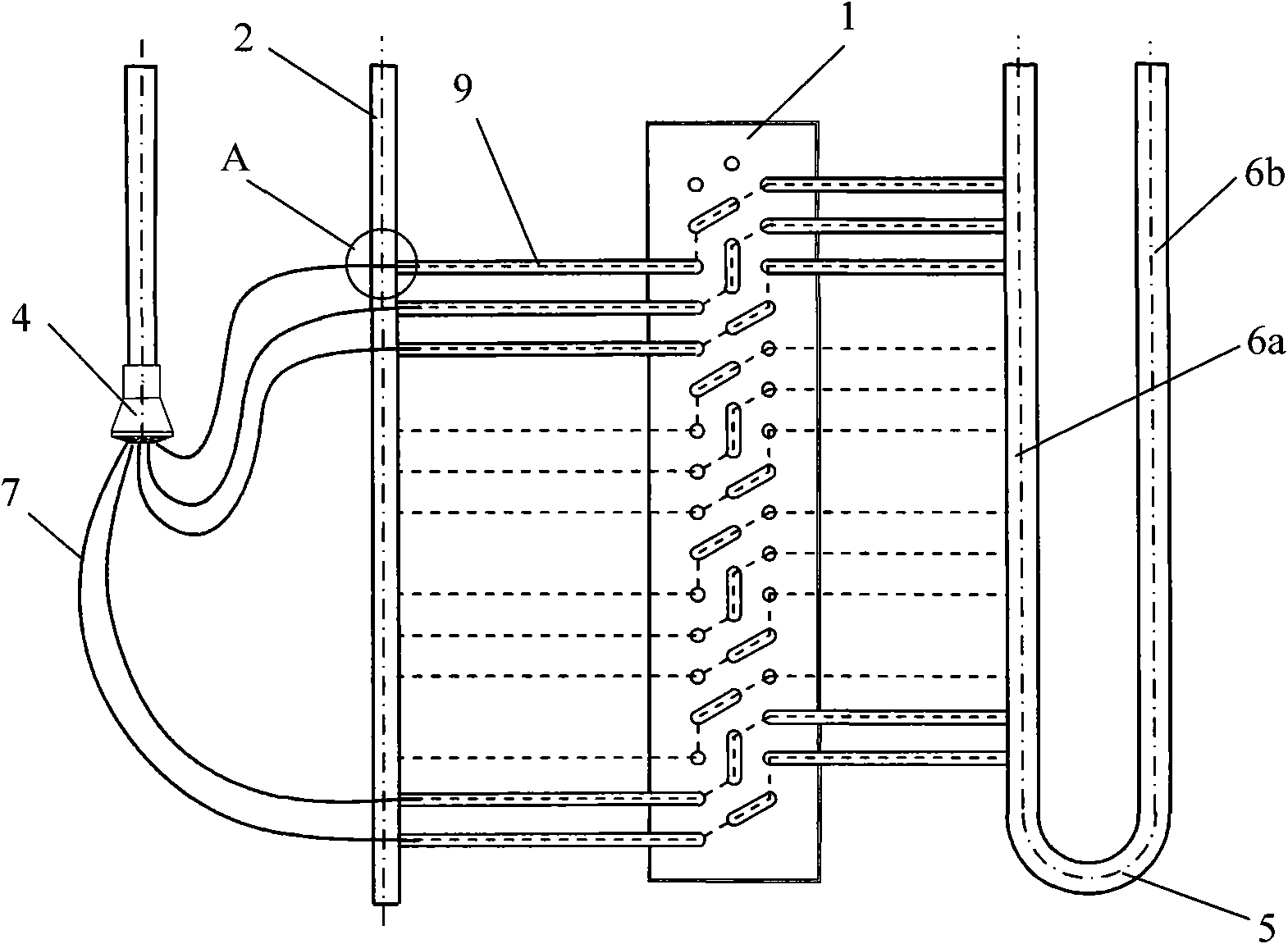

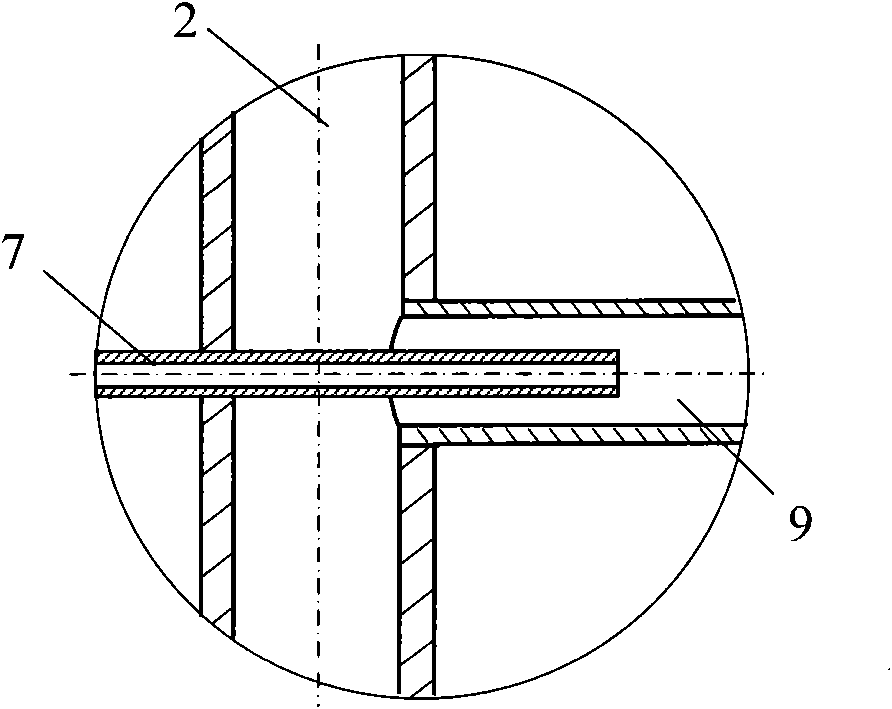

[0024] figure 2 , image 3 It is the structural principle diagram of the "special evaporator for heat pipe refrigeration composite air conditioner" disclosed by the present invention. The special evaporator for heat pipe refrigeration composite air conditioner includes a finned tube heat exchanger 1, an air collecting pipe 3, a liquid distributor 4, a liquid distributor 7 and a heat exchange tube 9, and the heat exchange tube 9 and the liquid distributor 7 A liquid collection pipe 2 is arranged between them, and the heat exchange pipe 9 communicates with the liquid collection pipe 2, and the liquid distribution pipe 7 is inserted through the liquid collection pipe 2 and extends into the heat exchange pipe 9; the gas collection pipe 3 adopts a U-shaped pipe, The U-shaped tube is composed of a first rising riser 6a, a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com