Underwear steel ring sleeve and method for manufacturing underwear

一种钢圈套、内衣的技术,应用在胸衣、服饰、应用等方向,能够解决钢圈套无蓬松感、钢圈插入受阻、褶皱或孔洞等问题,达到提升舒适感的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

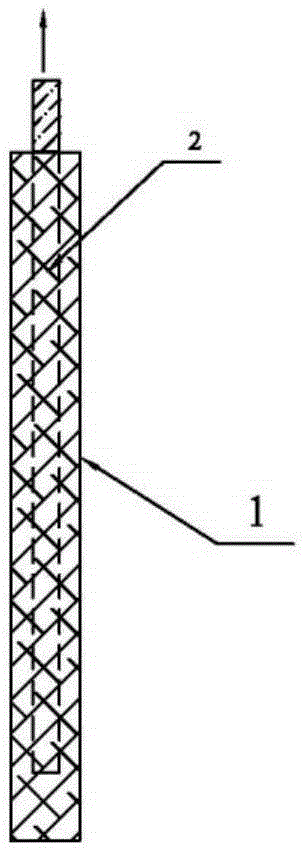

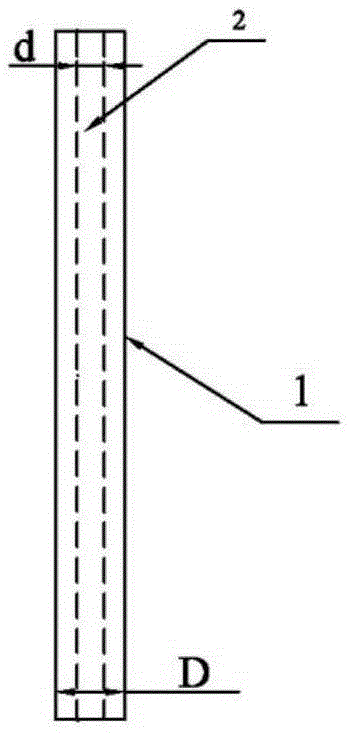

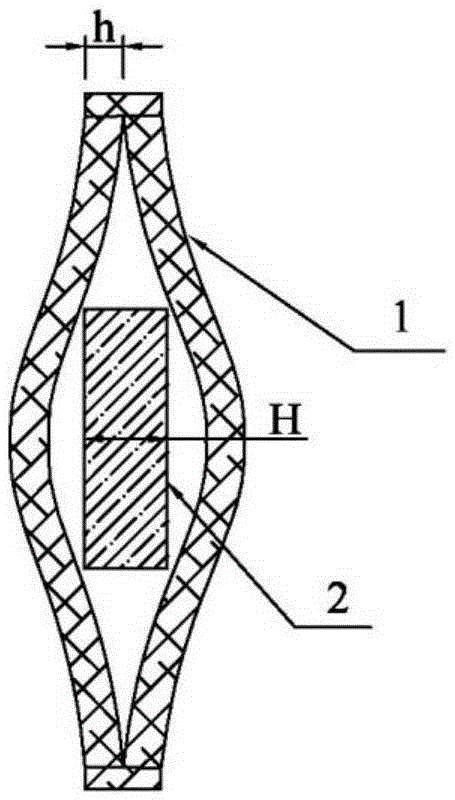

[0022] The present invention will be further described below in combination with specific embodiments. Among them, the accompanying drawings are only for illustrative purposes, and only represent schematic diagrams, rather than physical diagrams, and should not be construed as limitations on this patent;

[0023] Such as Figures 1 to 3 As shown, an underwear rim cover of the present invention includes a hollow cover body made of cloth. The hollow cover body has a hollow part for accommodating the steel ring to be installed, and also includes: a core wire inserted in the hollow position, and the core wire slides relative to the hollow casing. The core wire 2 is relatively independent from the hollow casing 1, and the core wire 2 can be pulled out as required. The length of the core wire 2 is not less than the length of the hollow casing 1, and a better choice is that the length of the core wire is equal to the length of the hollow casing. The width d and thickness h of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com