Paper rolling mechanism for printing machine

A technology for printing presses and printing presses, which is applied to the field of paper reeling mechanisms for printing presses, can solve the problems such as the loose card loading of the paper core, and achieve the effects of improving the use effect, convenient operation, and avoiding loose card loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A paper rolling mechanism for a printing machine of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings:

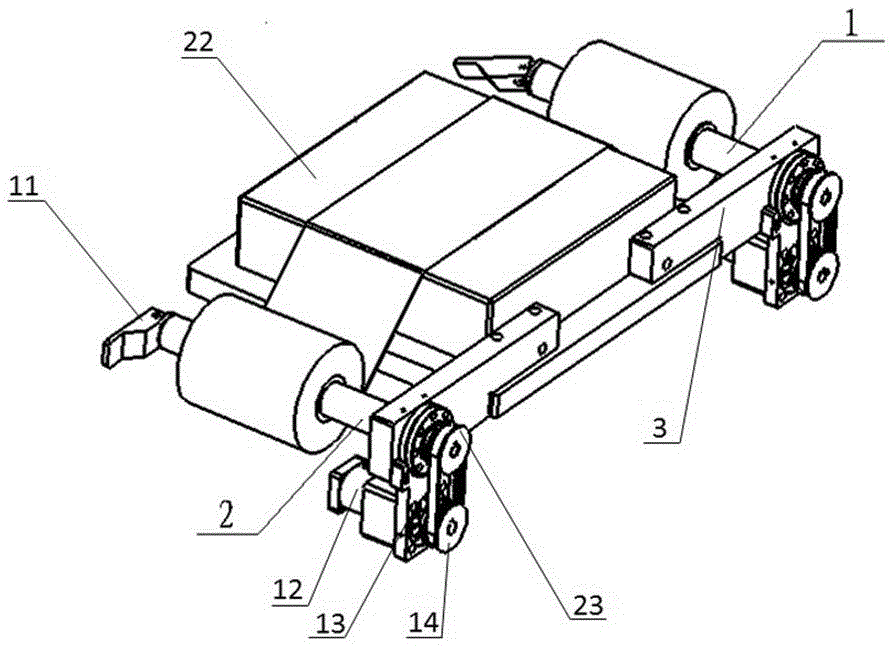

[0032] figure 1 Shown is a structural schematic diagram of a roll paper mechanism for a printing machine, which includes a paper upper part 1, a printing machine workbench 22, and a paper delivery part 2; wherein, the paper upper part 1 and paper delivery part 2 are fixed on the printing machine workbench 22 The roll paper is conveyed by the upper paper part 1, and is pulled to the delivery part 2 by the printing machine workbench 22, and the roll paper is closely attached to the printing machine workbench 22.

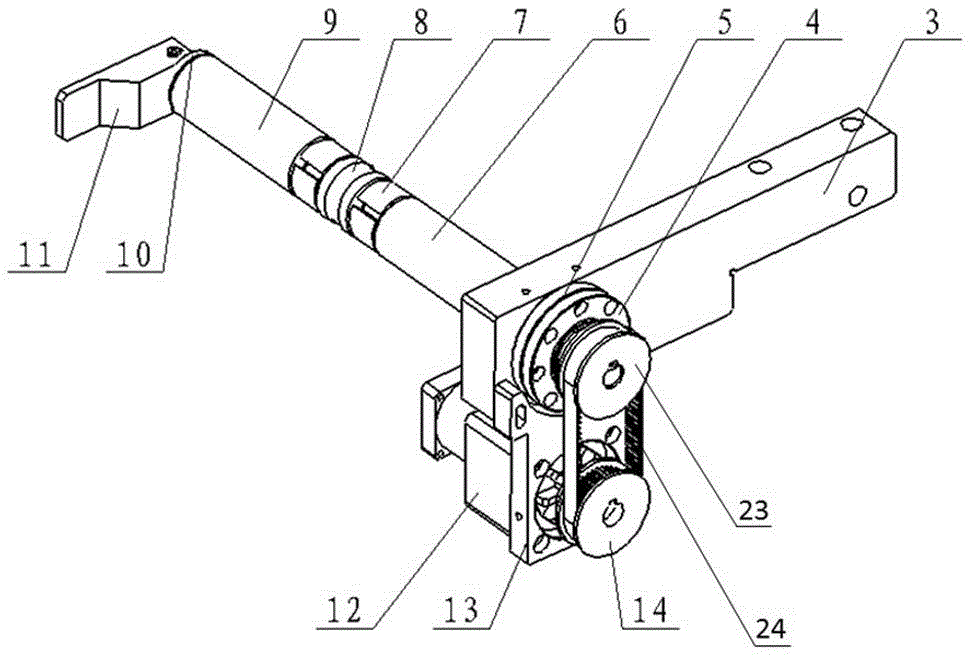

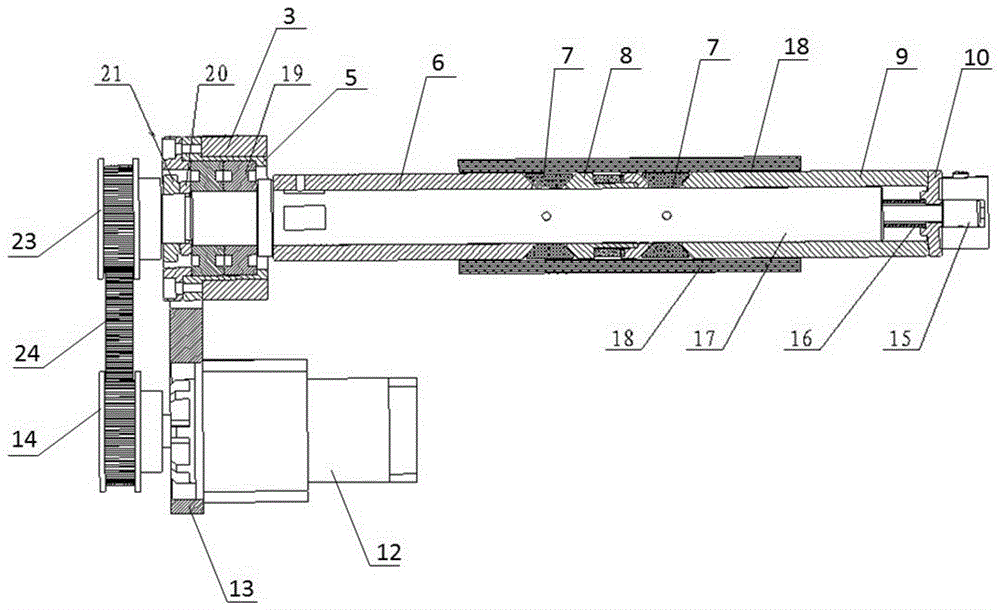

[0033] The upper paper part 1 and the paper delivery part 2 are fixed on the single-arm support plate 3 on the working table 22 of the printing press in a single cantilever manner. The upper paper part 1 and the paper delivery part 2 are independently driven to rotate by the driving devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com