Gas-lifting type two-phase partition membrane bioreactor

A membrane bioreactor, phase distribution technology, applied in separation methods, dispersed particle separation, air quality improvement and other directions, can solve the problems of low purification efficiency, small scope of application, and tail gas emissions that do not meet higher standards. The effect of complete destruction, huge market and broad industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

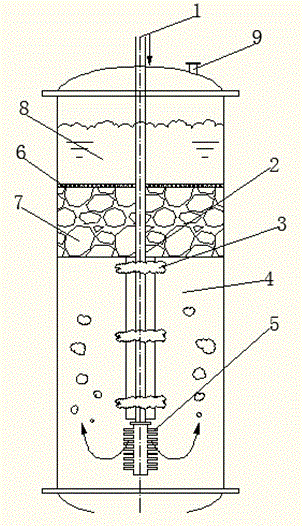

[0019] In order to express the patent of the present invention more clearly, the attached figure 1 The present invention is further described.

[0020] An air-lift two-phase distribution membrane bioreactor, mainly composed of an air inlet 1, a gas pipeline 2, a non-aqueous medium 3, a mixed liquid (aqueous phase area) 4, an air injection pipe 5, a biofilm 6, and a microbial reaction area 7. It is composed of tail gas area 8 and exhaust pipe 9.

[0021] The air inlet 1 is located at the center of the upper end of the casing, and the exhaust tube 9 is placed at the upper end of the casing (on the side of the air inlet). The casing is provided with an exhaust gas zone 8, a microbial reaction zone 7, and an aqueous phase zone 4 sequentially from top to bottom, and the exhaust tube (9) communicates with the exhaust gas zone 8.

[0022] The gas pipeline 2 is located on the center line (central axis position) of the whole device, and leads to the bottommost position of the mixed l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com