Pour point depressing and viscosity reducing composition for heavy oil, pour point depressing and viscosity reducing agent for heavy oil and preparation method of pour point depressing and viscosity reducing agent

A technology of composition and viscosity reducing agent, which is applied in the field of heavy oil pour point depressing composition, can solve the problems of unsatisfactory pour point depressing effect of heavy oil, single viscosity reducing performance, poor pour point depressing effect of heavy oil with high pour point, etc. Achieve the effect of realizing emulsion stabilization, improving oil recovery efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

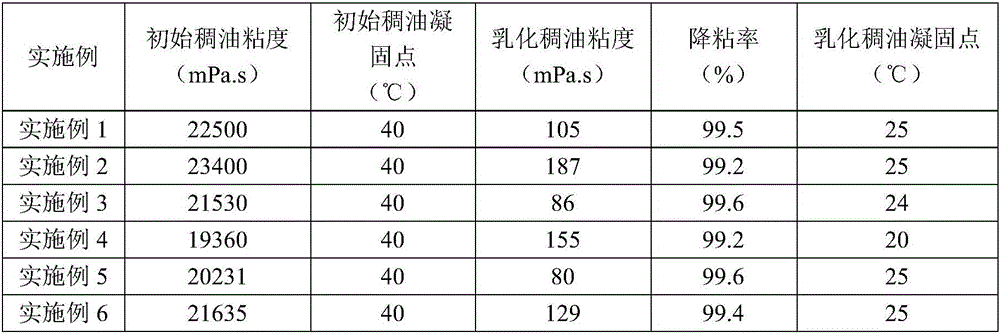

Examples

Embodiment 1

[0038] The heavy oil pour point and viscosity reducing composition of the present embodiment is composed of the following components by weight: 30g surfactant nonylphenol polyoxyethylene ether sodium sulfate, 10g dispersant, 15g inhibitor edetate disodium, 30g co-emulsifier sodium lignosulfonate;

[0039] The dispersant is made by mixing 2g of sodium petroleum sulfonate and 8g of octadecylamine polyoxyethylene ether;

[0040] The degree of polymerization of the polyoxyethylene group in the nonylphenol polyoxyethylene ether sodium sulfate is 10, and the degree of polymerization of the polyoxyethylene group in the stearylamine polyoxyethylene ether is 10.

[0041] The pour point and viscosity reducer for heavy oil in this embodiment is prepared from the above thick oil pour point and viscosity reducer composition and 15 g of water.

[0042] The preparation method of the heavy oil pour point and viscosity reducer of the present embodiment comprises the steps:

[0043] Add the i...

Embodiment 2

[0045] The thick oil pour point and viscosity reducing composition of the present embodiment is made up of the following components by weight: 40g surfactant sodium pentadecyl alcohol polyoxyethylene ether sulfonate, 5g dispersant stearylamine polyoxyethylene ether, 18g inhibitor Aminotriacetic acid, 25g co-emulsifier sodium lignosulfonate;

[0046] The degree of polymerization of the polyoxyethylene group in the above-mentioned sodium pentadecyl alcohol polyoxyethylene ether sulfonate is 2, and the degree of polymerization of the polyoxyethylene group in the stearylamine polyoxyethylene ether is 12;

[0047] The pour point and viscosity reducer for heavy oil in this embodiment is made from the above heavy oil point point and viscosity reducer composition and 12 g of water.

[0048] The preparation method of the heavy oil pour point and viscosity reducer of the present embodiment comprises the steps:

[0049] Add the inhibitor to 12 g of deionized water, stir until the inhibi...

Embodiment 3

[0051] The heavy oil pour point and viscosity reducing composition of the present embodiment consists of the following components by weight: 50g surfactant sodium stearyl polyoxyethylene ether sulfonate, 12g dispersant, 15g inhibitor ammonium citrate, 20g emulsifying aid Sodium lauryl polyether sulfonate;

[0052] The dispersant is made by mixing 10g of sodium petroleum sulfonate and 2g of octadecylamine polyoxyethylene ether;

[0053] The degree of polymerization of the polyoxyethylene group in the above-mentioned sodium stearyl polyoxyethylene ether sulfonate is 3, and the degree of polymerization of the polyoxyethylene group in the stearylamine polyoxyethylene ether is 30.

[0054] The pour point and viscosity reducer for heavy oil in this embodiment is prepared from the above heavy oil point point and viscosity reducer composition and 3 g of water.

[0055] The preparation method of the heavy oil pour point and viscosity reducer of the present embodiment comprises the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com