A kind of wear-resistant impregnated film paper and preparation method thereof

A technology of impregnating film paper and wear-resistant triamine glue, applied in papermaking, paper, textile and papermaking, etc., can solve the problems of reducing wear resistance, high brittleness of glue, and low consumption of urea, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

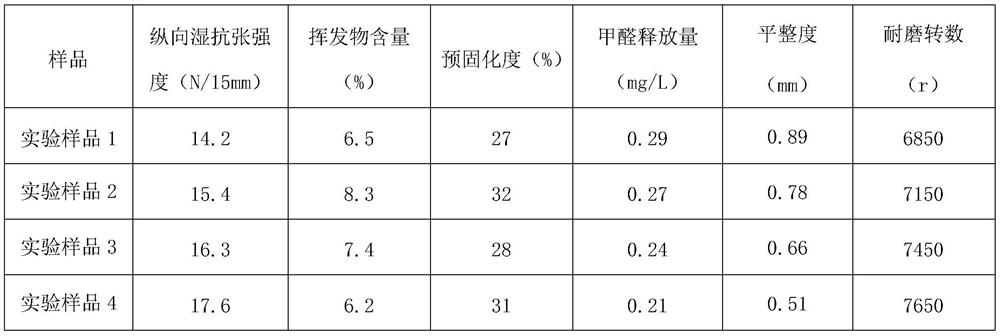

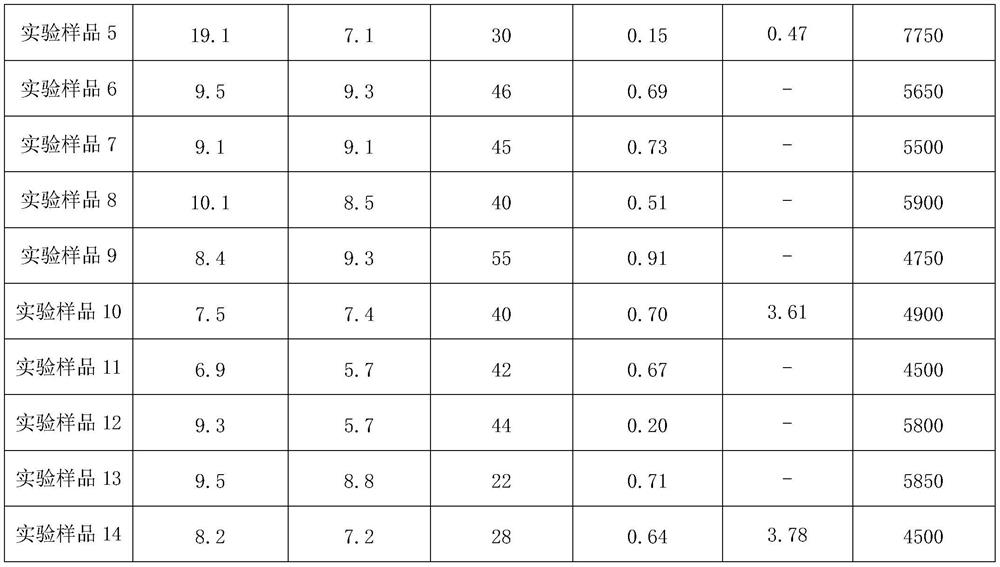

Examples

Embodiment 1

[0032] A preparation method for wear-resistant impregnated film paper, comprising the following steps:

[0033] a. Preparation of wear-resistant melamine glue: according to the weight ratio, take 2075 parts of formaldehyde and 500 parts of water and add them to the reaction kettle, add sodium hydroxide aqueous solution to adjust the pH value to 8.8, then add 1850 parts of melamine, and then pass in carbon dioxide gas , then raise the temperature to 93°C, add sodium hydroxide aqueous solution to adjust the pH value to 9.3, continue to keep the temperature at 93°C for 22 minutes, then start to measure the water solubility ratio, and when the reaction reaches 100 minutes, the measured water solubility ratio is 1.9 , use sodium hydroxide aqueous solution to adjust the pH value to 9.3, then lower the temperature, and then when the temperature drops to 72°C, add 150 parts of 301 additives, continue to keep the temperature at 72°C, react for 40 minutes, and then measure the water solu...

Embodiment 2

[0044] A preparation method for wear-resistant impregnated film paper, comprising the following steps:

[0045] a. Preparation of wear-resistant melamine glue: according to the weight ratio, take 2395 parts of formaldehyde and 800 parts of water and add them to the reaction kettle, add sodium hydroxide aqueous solution to adjust the pH value to 9.1, then add 1870 parts of melamine, and then pass in carbon dioxide gas , then raise the temperature to 95°C, add sodium hydroxide aqueous solution to adjust the pH value to 9.5, continue to keep the temperature at 95°C for 40 minutes, and start to measure the water-soluble ratio. When the reaction reaches 150 minutes, the measured water-soluble ratio is 2.2 , use sodium hydroxide aqueous solution to adjust the pH value to 9.5, then lower the temperature, and then when the temperature drops to 82°C, add 250 parts of 301 additives, continue to maintain the temperature at 82°C, react for 50 minutes, and then measure the water solubility ...

Embodiment 3

[0056] A preparation method for wear-resistant impregnated film paper, comprising the following steps:

[0057] a. Preparation of wear-resistant melamine glue: according to the weight ratio, take 2350 parts of formaldehyde and 600 parts of water and add them to the reaction kettle, add sodium hydroxide aqueous solution to adjust the pH value to 8.9, then add 1855 parts of melamine, and then pass in carbon dioxide gas , then raise the temperature to 94°C, add sodium hydroxide aqueous solution to adjust the pH value to 9.4, continue to keep the temperature at 94°C for 26 minutes, and then start to measure the water solubility ratio. When the reaction reaches 110 minutes, the measured water solubility ratio is 2.0 , adjust the pH value to 9.4 with aqueous sodium hydroxide solution, then lower the temperature, and then when the temperature drops to 75°C, add 175 parts of 301 additives, continue to maintain the temperature at 75°C, react for 43 minutes, and then measure the water so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com