Method for flexible immobilization of papain by modified polyacrylonitrile resin

A technology of polyacrylonitrile resin and papain, which is applied in the direction of immobilization on/in the organic carrier, can solve the problem of low recovery rate of immobilized enzyme activity, achieve high atom utilization, mild immobilization process, and relatively The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

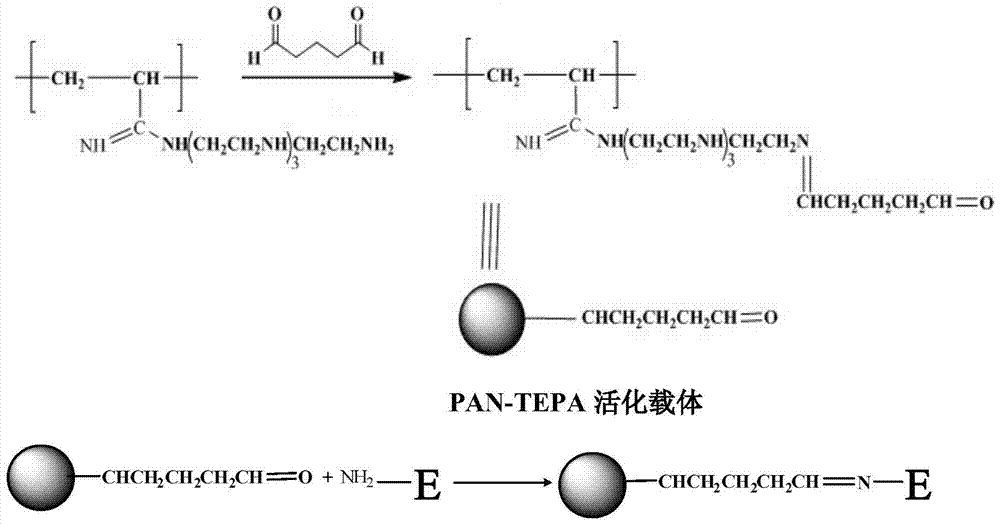

[0062] Embodiment 1, a kind of method for the flexible immobilization papain of modified polyacrylonitrile resin, carries out following steps successively:

[0063] 1), prepare flexible carrier, carry out the following steps in sequence:

[0064] ①, polyacrylonitrile resin modification:

[0065] Accurately weigh 1.00g of polyacrylonitrile resin microspheres (PAN) into a 500mL three-neck bottle, then add 300mL of reaction solvent (ethylene glycol --- ED), soak and swell at room temperature (20-30°C) for 24 hours, Add 11.89g of tetraethylenepentamine (TEPA), and a little catalyst---NaOH (0.12g), and turn on nitrogen, stir at room temperature with a stirring speed of 200rpm for 2h, then rapidly rise to 80°C, magnetic stirring ( 200rpm) for 10 hours, and filtered to obtain modified polyacrylonitrile resin microspheres.

[0066] ②. Soak the modified polyacrylonitrile resin microspheres with 50ml of reaction solvent (ethylene glycol—ED) for 3 hours, then wash with reaction solvent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com