Low-temperature-resistant polypropylene clothing packaging film and preparation method thereof

A packaging film and polypropylene technology, applied in the field of clothing accessories, can solve the problems of high friction resistance, powder output and high cost, and achieve the effects of strong interface bonding force, improved low temperature resistance and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

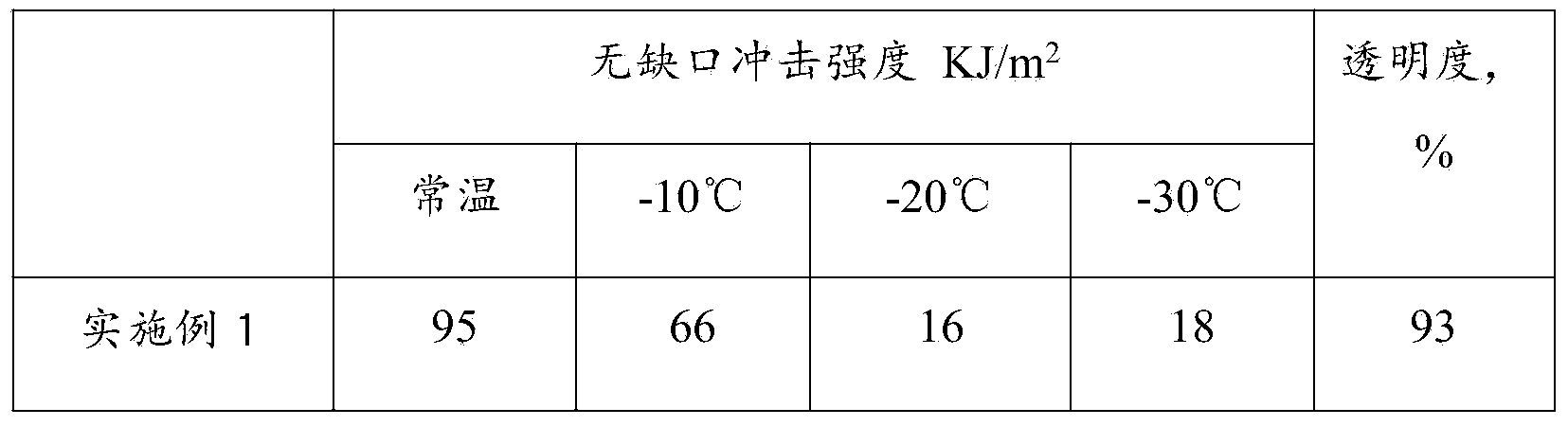

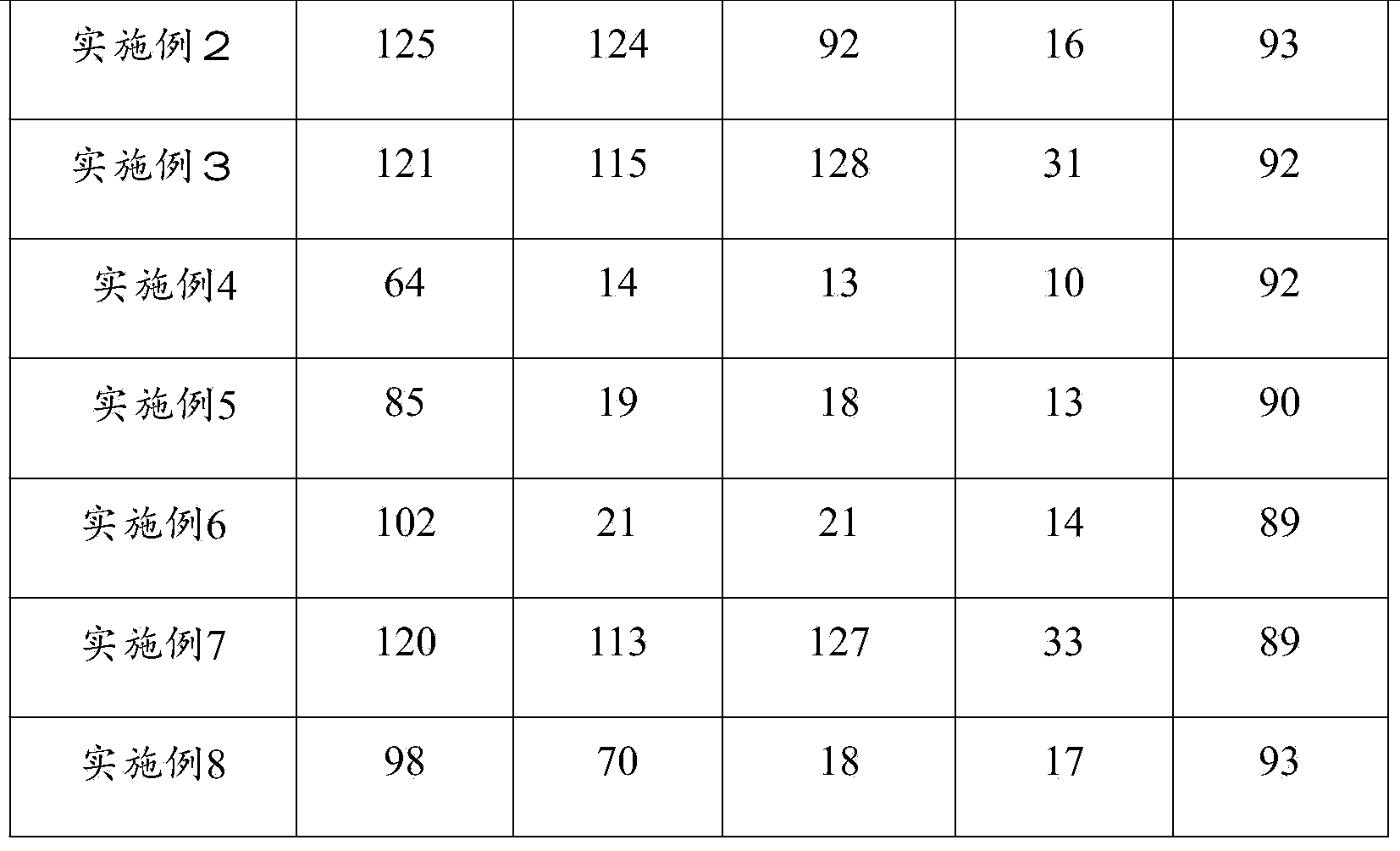

Examples

Embodiment 1

[0027] The preparation method of the low temperature resistant polypropylene clothing packaging film described in the present embodiment comprises the following steps:

[0028] (1) The homopolypropylene that is 92wt% by weight percentage, the modified polypropylene of 7.5wt% and the anti-adhesive agent of 0.5wt% are mixed at high speed by high-speed mixer for 3 minutes;

[0029] (2) the mixed raw material of step (1) gained is packed in the down-blowing water-cooled film blowing machine, evenly disperses and extrudes the blown film to obtain the polypropylene film cylinder;

[0030] (3) the polypropylene film cylinder material of step (2) gained just can obtain garment packaging bag through surface printing and slitting operation again;

[0031] Among them, the temperature of the down-blowing water-cooled film blowing machine is: 175°C in the first zone, 180°C in the second zone, 185°C in the third zone, 185°C in the fourth zone, 180°C in the fifth zone, and 175°C at the head....

Embodiment 2

[0039] The preparation method of the low temperature resistant polypropylene clothing packaging film described in the present embodiment comprises the following steps:

[0040] (1) The homopolypropylene that is 82wt% by weight percentage, the modified polypropylene of 16.5wt% and the anti-caking agent of 1.5wt% are mixed 5 minutes at high speed by high-speed mixer;

[0041] (2) the mixed raw material of step (1) gained is packed in the down-blowing water-cooled film blowing machine, evenly disperses and extrudes the blown film to obtain the polypropylene film cylinder;

[0042] (3) The polypropylene film tube material of step (2) gained can obtain the garment packaging bag through surface printing and slitting process again.

[0043] Among them, the temperature of the down-blown water-cooled film blowing machine is: 185°C for the first zone, 185°C for the second zone, 190°C for the third zone, 190°C for the fourth zone, 185°C for the fifth zone, and 180°C for the machine head....

Embodiment 3

[0051] Add 75wt% homopolypropylene, 22wt% modified polypropylene, and 3wt% anti-caking agent into the high-speed mixer, and the rest of the processes and tests are the same as in Example 1. The modified polypropylene in this embodiment is composed of repeating units of isotactic polypropylene and randomly distributed ethylene, the content of the ethylene is 17 wt%, and the non-migrating particulate anti-adhesive agent is carbon dioxide Silicone anti-adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com