Inferior coal micro-oil ignition combustor

A micro-oil ignition, oil burner technology, applied in burners, burners burning powder fuel, combustion ignition and other directions, can solve the problems of excess oxygen in low temperature areas, no cooling measures, large blocked flow area, etc. The effect of high ember rate, good environmental protection effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

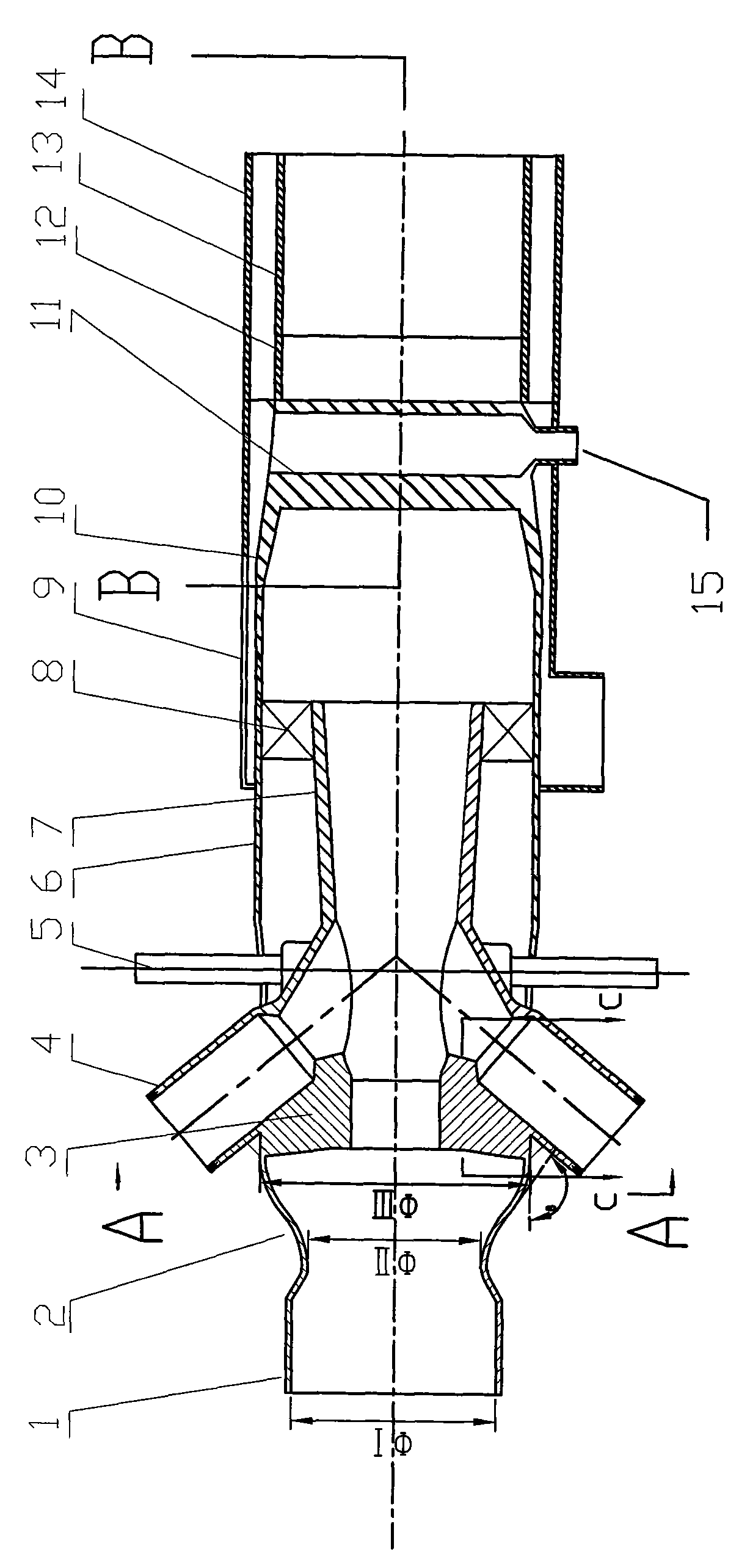

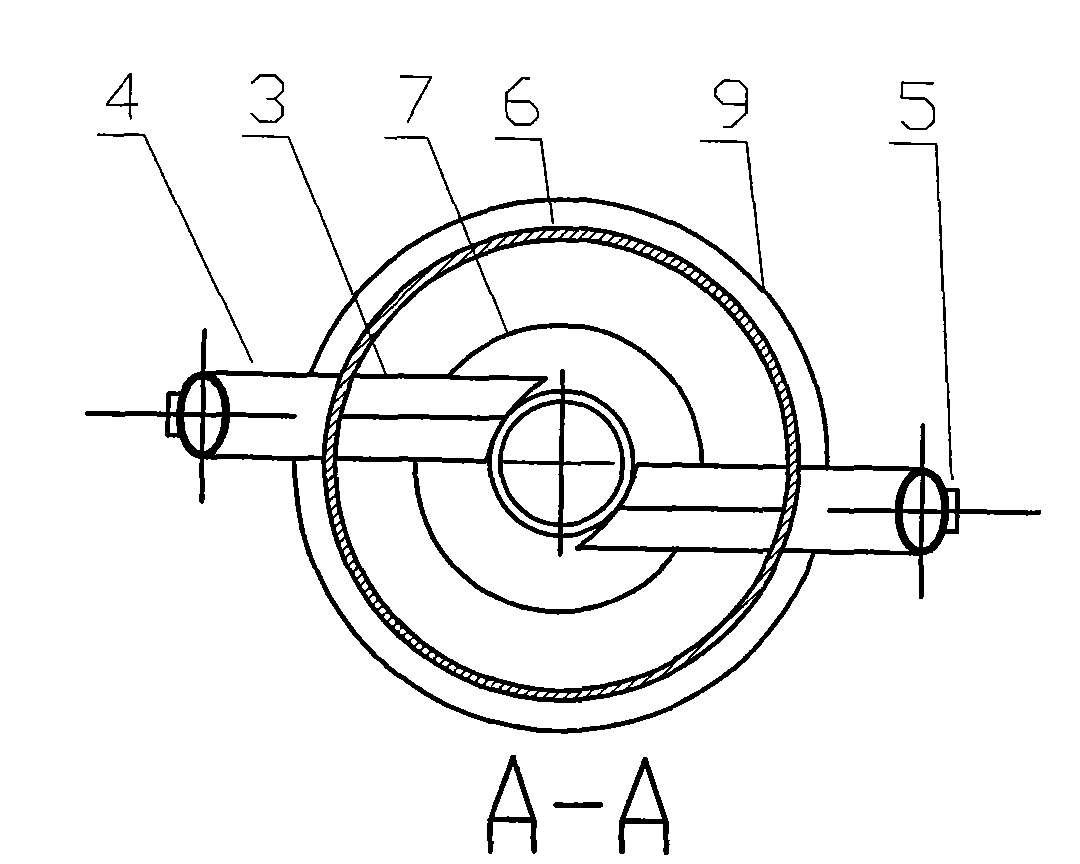

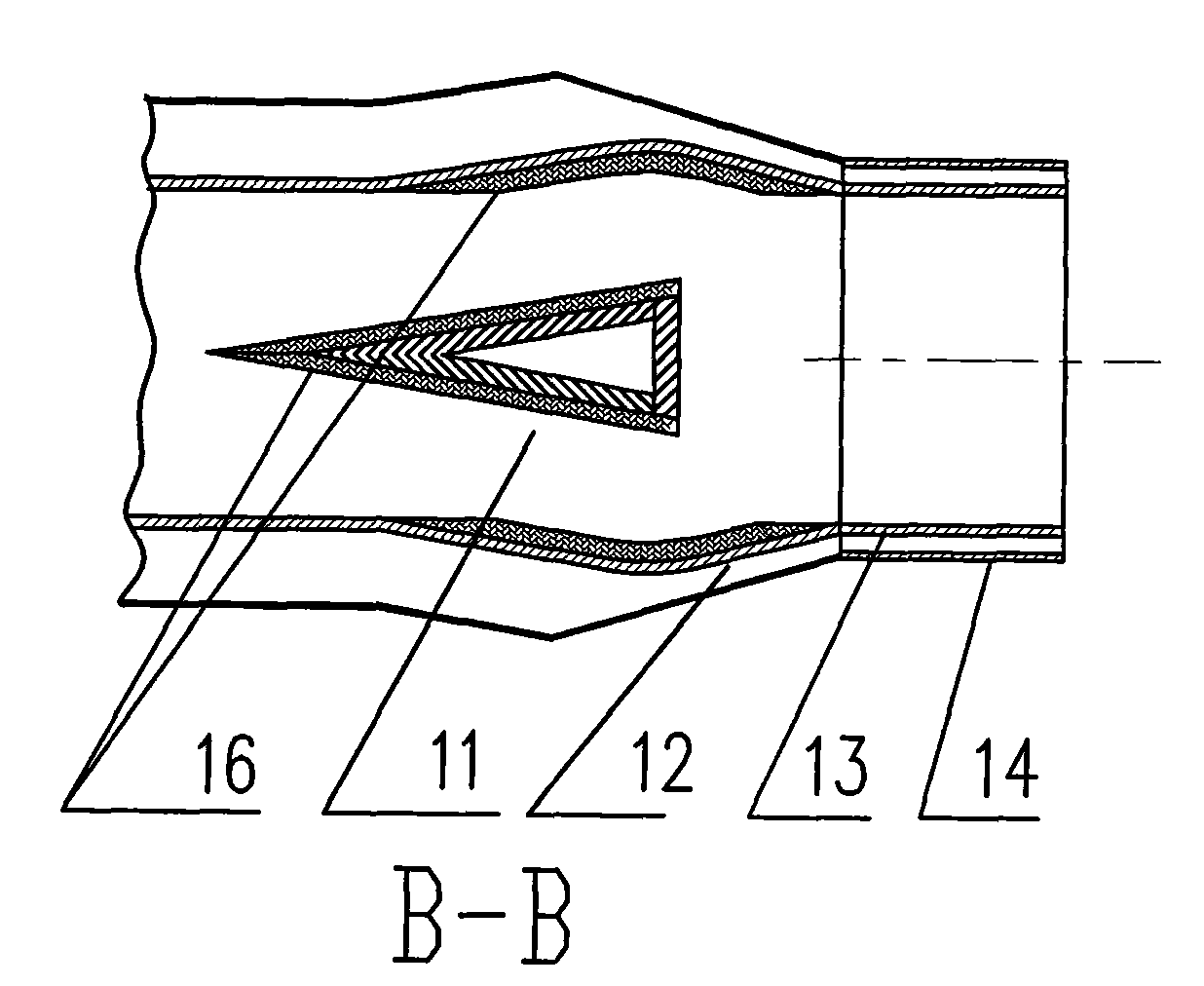

[0027] Embodiment: In the low-quality coal micro-oil ignition burner in the figure, its inlet section (1) is connected with the original pulverized coal pipe, and the air powder separation ring (2) is installed between the inlet section (1) and the light-phase pulverized coal chamber ( 6); the first-level dense-phase pulverized-coal ignition chamber (7) is installed inside the light-phase pulverized-phase coal chamber (6) and is connected with it by a rib plate (8); two oil burners (4) are contained in one The two sides of the dense-phase pulverized coal ignition chamber (7) pass through the light-phase pulverized coal chamber (6); there is a wing-shaped anti-wear block (3) in the powder incoming direction of the oil burner (4), which is connected with the oil burner (4). The burner (4), the primary dense phase pulverized coal ignition chamber (7), and the light phase pulverized coal chamber (6) are welded into one; the flame detection tube (5) is mounted on the oil burner (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com