Electroosmosis dewatering method and device of water-containing material

A dehydration device and electro-osmosis technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of low space utilization and affect the overall efficiency of the dehydrator, and achieve stability, device simplification, equipment simplification, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

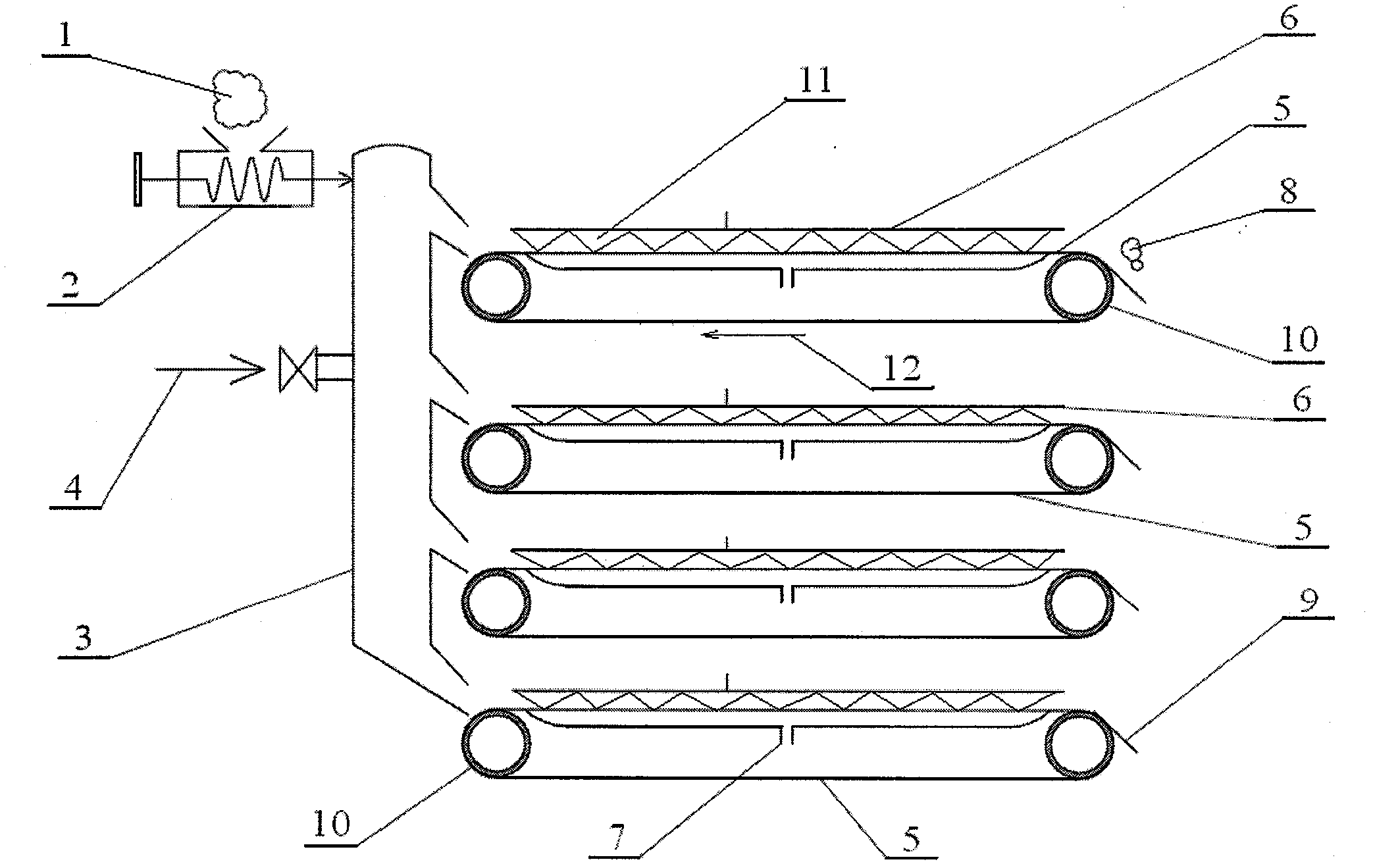

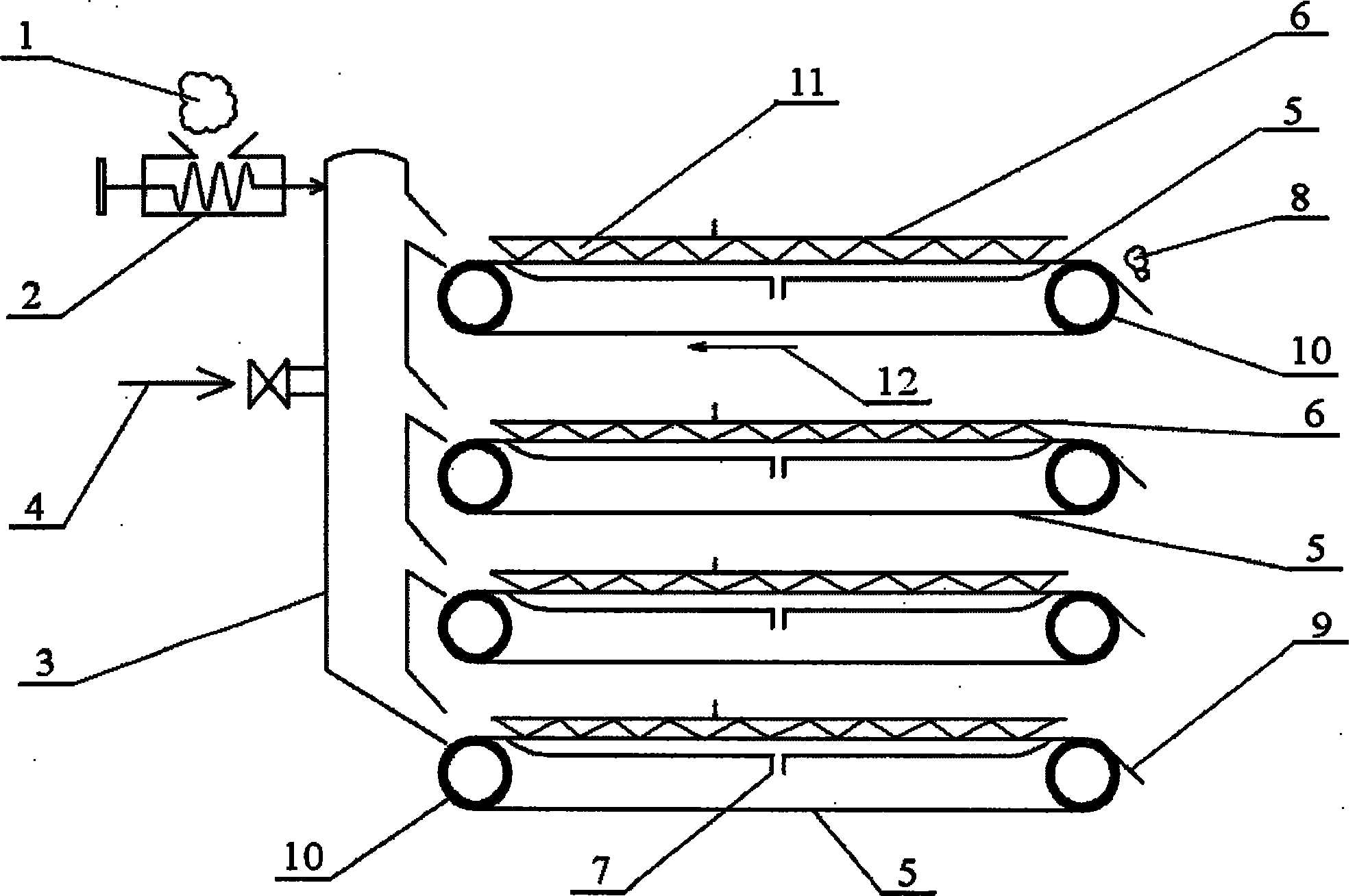

[0023] This example is an example of electroosmotic dehydration of sewage sludge. Such as figure 1 The dewatering unit shown is a sludge dewaterer with 4 layers of electro-osmosis units. The filtered sludge 1 is sent to the sludge distributor 3 through the sludge booster pump 2, and then the sludge is pressed to the stainless steel mesh belt cathode 5 through the compressed air 4, and stops after entering the dehydration area as the cathode belt moves. move. The anode 6 made of insoluble metal descends, contacts with the sludge and applies pressure properly, and direct current (power supply not shown in the figure) is introduced. Under the action of the electric field, the moisture in the sludge gathers to the sludge side of the cathode, and further under the mechanical pressure of the anode and cathode wire mesh, the accumulated water permeates the metal mesh of the cathode from the support mechanism set under the cathode belt Water outlet 7 discharges. When the dehydrati...

Embodiment 2

[0025] This example is an example of electroosmotic dehydration of distiller's grains and food residues. The structure of the electroosmotic dehydration device is basically as follows: figure 1 As shown, the difference is the water-containing material dehydrator with 6 layers of electroosmotic units, and the material in this example corresponds to the sludge in Example 1. Among them, the upper 2 dehydration units, the middle 2 dehydration units, and the lower 2 dehydration units form 3 groups respectively. The 3 groups operate in chronological order, that is, from top to bottom, and divide into 3 times within the time period. The time difference of the segment performs the action respectively. The feed pump is provided with 3 outlets to supply material to the material distributors of the upper, middle and lower units respectively. The angle between the cathode and anode planes relative to the horizontal is 0 degrees. The initial material thickness is controlled between 6 an...

Embodiment 3

[0027] The dehydration device is the same as that of Example 1, except that the cathode belt is inclined upward by 8 degrees from the material inlet to the outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com