Auxiliary automatic separator for clutch of hydraulic mixed power city bus

An urban bus and hybrid technology, which is applied in the field of hydraulic hybrid urban bus clutch auxiliary automatic separation device, can solve the problems affecting the energy saving effect of hydraulic hybrid bus and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

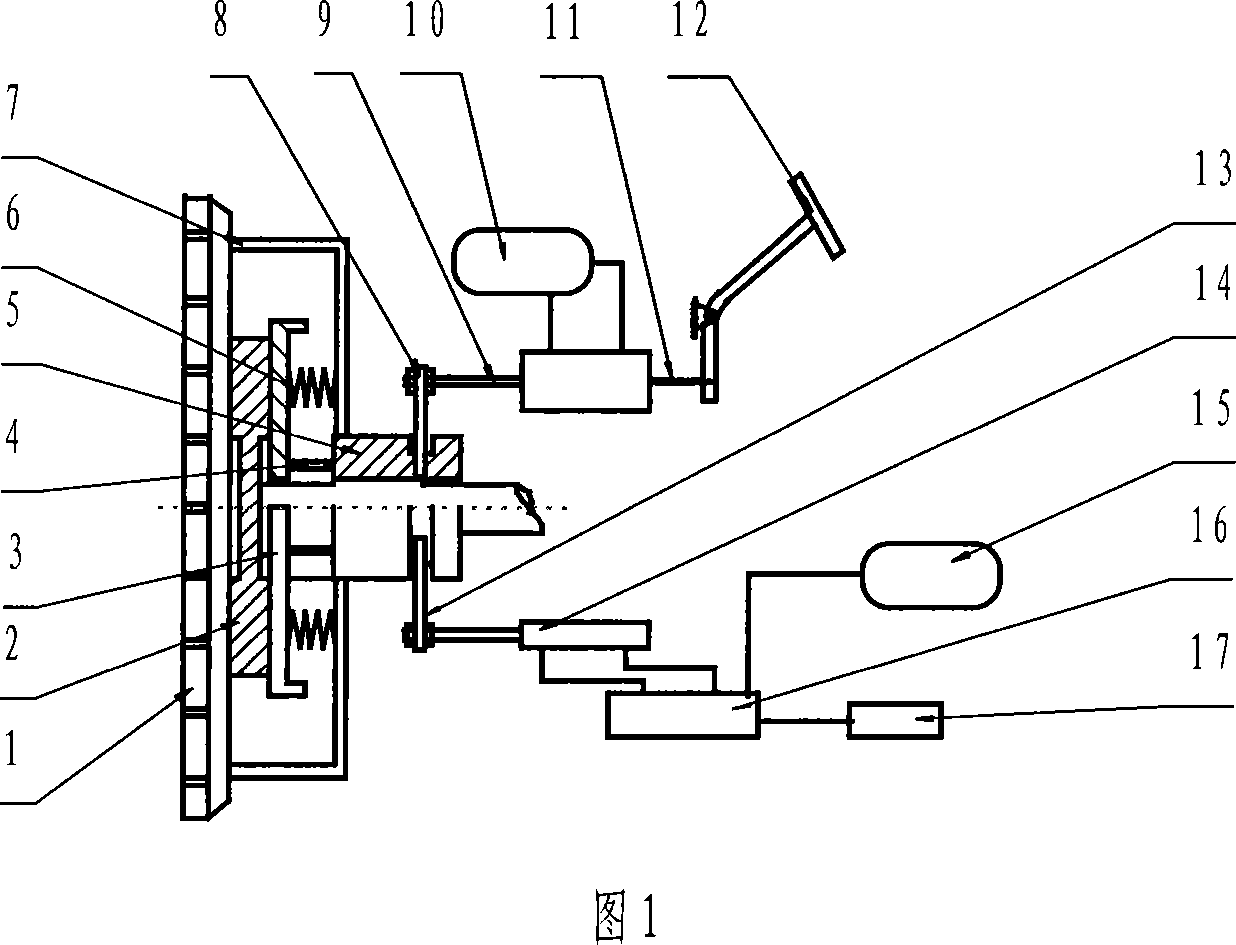

[0010] As shown in Figure 1, the present invention mainly includes: flywheel 1, friction plate 2, pressure plate 3, pressure plate pull rod 4, sliding sleeve 5, pressure plate compression spring 6, clutch bracket 7, hydraulic booster shift fork 8, hydraulic booster pump 9. Hydraulic accumulator 10, clutch pedal connecting rod 11, clutch pedal 12, pneumatic booster shift fork 13, cylinder 14, air storage tank 15, pneumatic control valve 16, CUP controller 17, etc., flywheel 1, friction plate 2, pressure Disc 3, pressure plate pull rod 4, sliding sleeve 5, pressure plate compression spring 6, clutch shift fork 7, hydraulic booster shift fork 8, hydraulic booster pump 9, hydraulic accumulator 10, clutch pedal connecting rod 11, clutch pedal 12 The clutch pedal separation device is formed, and the pneumatic power-assisted shift fork 13, the cylinder 14, the air reservoir 15, the pneumatic control valve 16, and the CPU controller 17 constitute the clutch-assisted automatic separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com