Caterpillar water chestnut combine harVester

A combine harvester and crawler-type technology, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the constraints of water chestnut intensification, large-scale production, separation effect needs to be further improved, and unit traction efficiency is low. problems, achieve good adhesion performance, prevent leaking, increase separation rate and removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

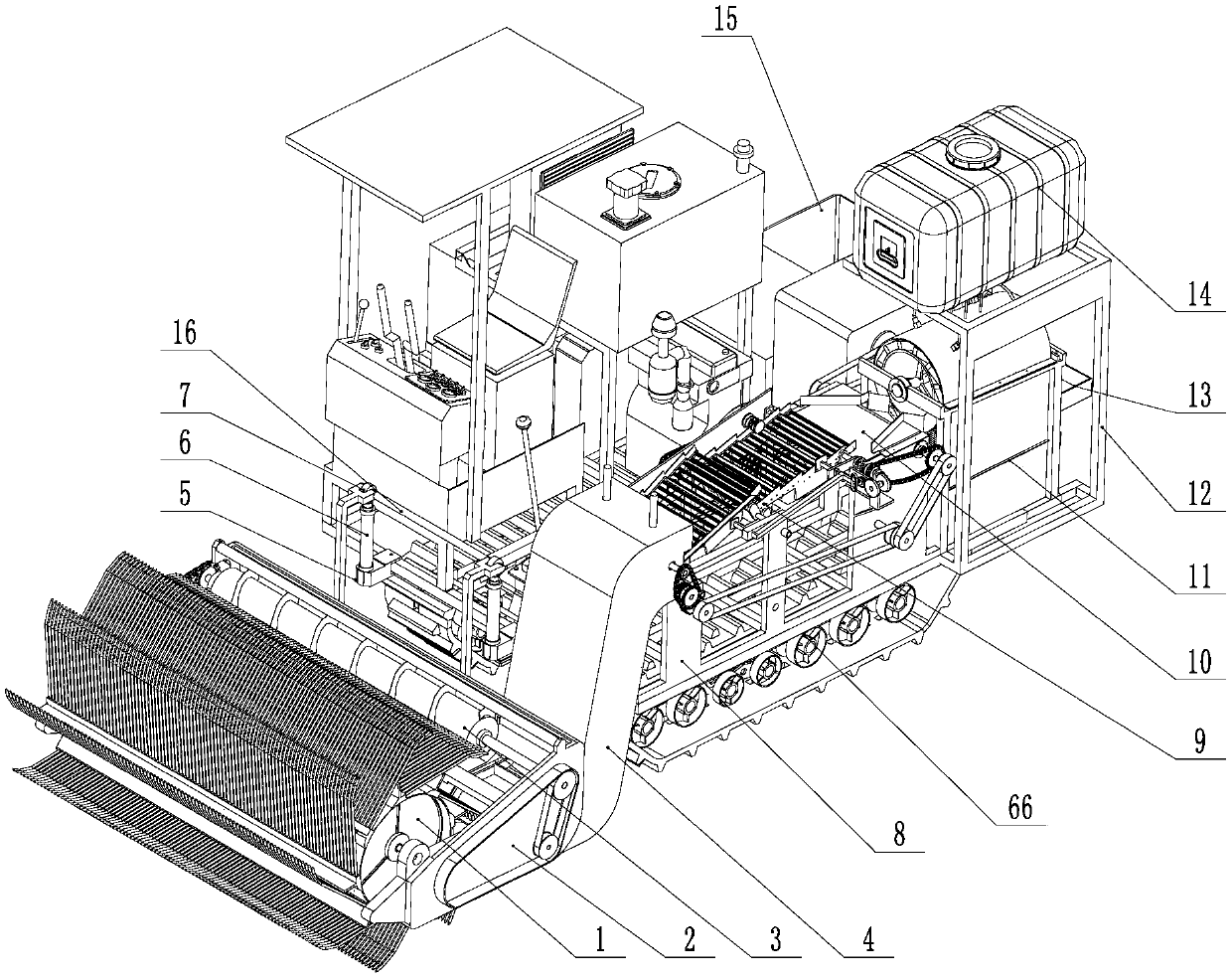

[0033] Such as figure 1 The tracked water chestnut combine harvester shown includes a chassis 66, a walking system installed below the chassis 66, an excavating system installed in front of the chassis 66, a two-way vibration separation system installed above the chassis 66, and a cleaning system installed behind the chassis 66 , And hydraulic lifting system. In this embodiment, the walking system is a crawler-type walking device, which is installed under and connected to the chassis 66.

[0034] The hydraulic lifting system includes a hydraulic system fixing frame 5 welded on the chassis 66, a hydraulic cylinder 6 and a hydraulic rod 7 fixed on the hydraulic system fixing frame 5.

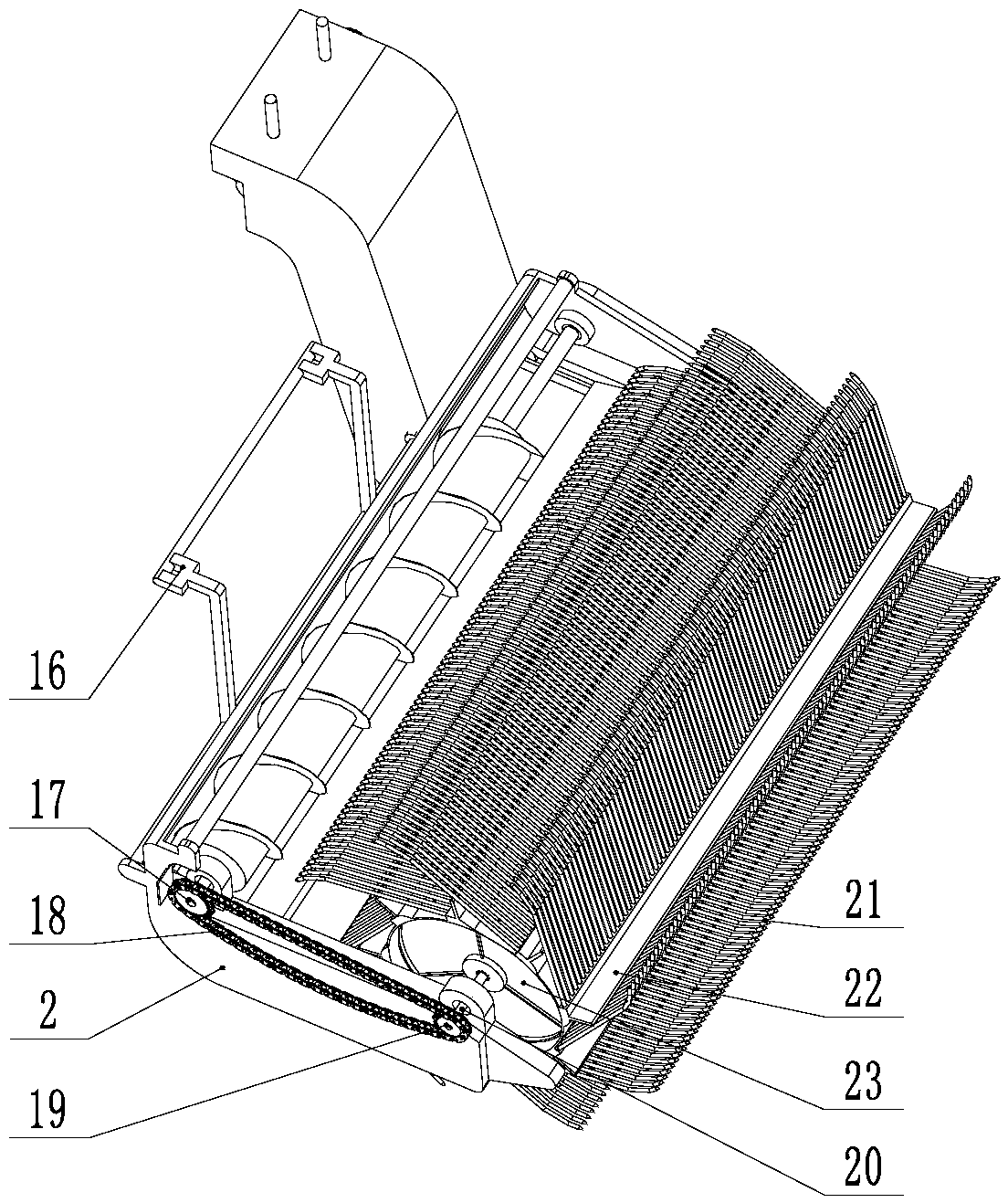

[0035] Combine figure 2 As shown, the excavating system includes an excavating platform 2, a rotary grid-type excavating shovel set at the front end of the excavating plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com