Drill jig for processing positioning holes of bead-fixed ring

A technology of positioning holes and drilling dies, which is applied to the drilling dies used for workpieces and other directions, can solve problems such as the influence of positioning hole machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

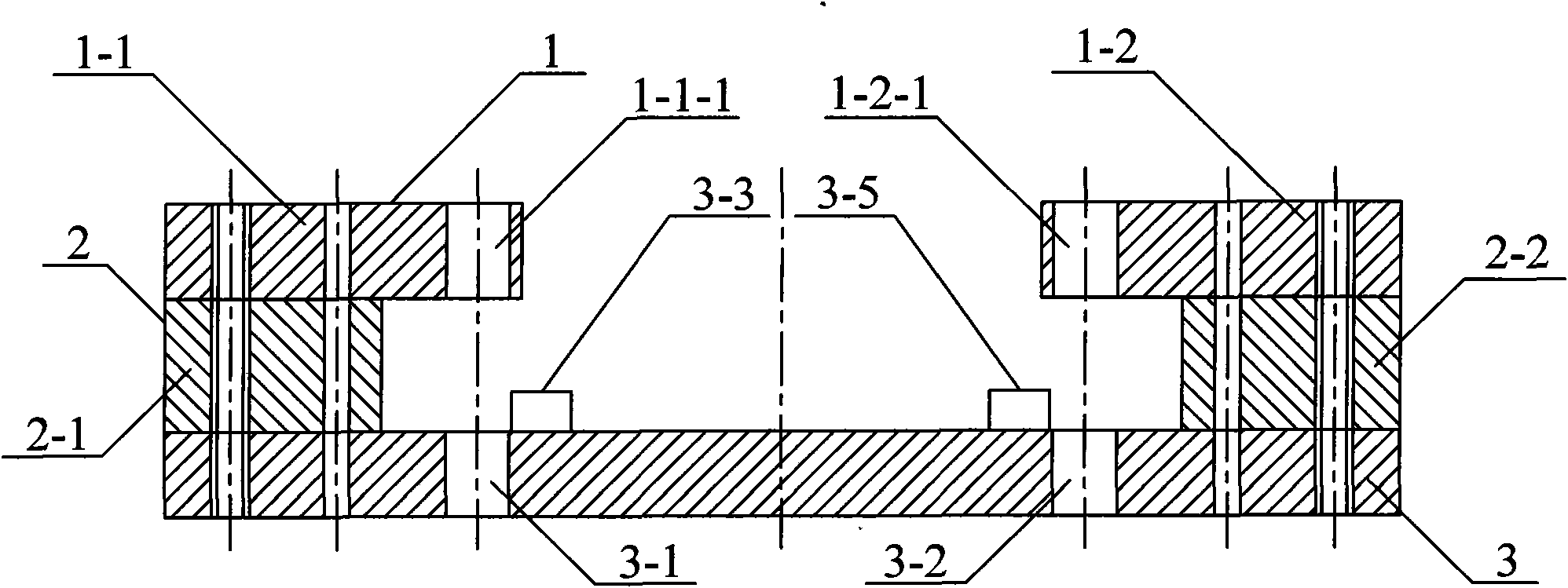

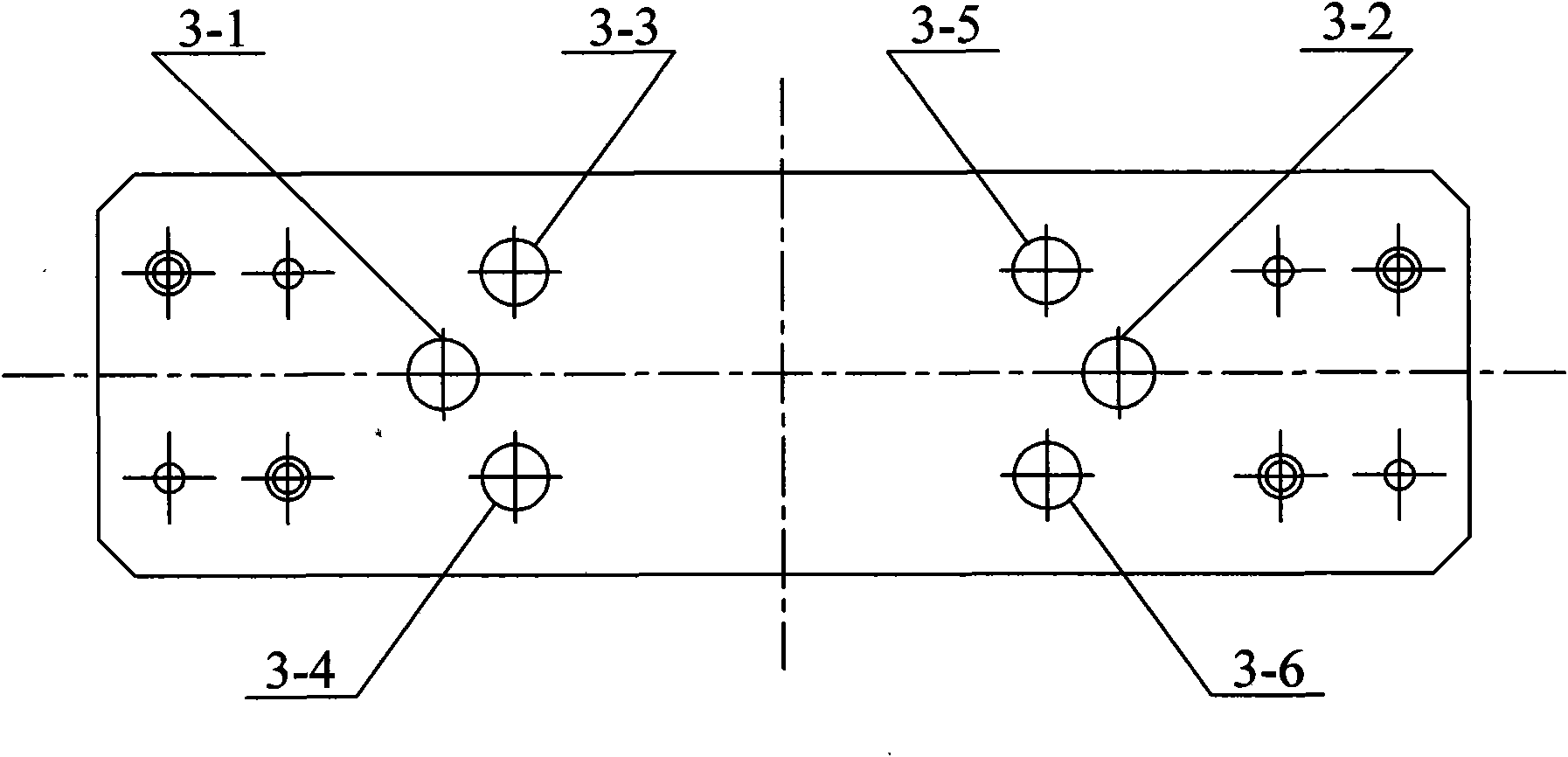

[0018] Such as figure 1 and figure 2 As shown, the drilling mold in this embodiment includes an upper mold 1 , a middle mold 2 and a lower mold 3 . The upper mold 1 is fixedly connected to the lower mold 3 through the middle mold 2 , and there is a space between the upper mold 1 and the lower mold 3 .

[0019] The upper mold 1 includes a first upper mold 1-1 and a second upper mold 1-2, and the middle mold 2 includes a first middle mold 2-1 and a second middle mold 2-2. The first upper mold 1-1 is connected to the left part of the lower mold 3 through the first middle mold 2-1 and by means of a pair of bolts and a pair of pins. Part of the first upper mold 1-1 is in contact with the first middle mold 2-1. On another part of the first upper die 1-1, a first upper die drill hole 1-1-1 is set. Similarly, the second upper mold 1-2 is connected to the right part of the lower mold 3 through the second middle mold 2-2 and by means of a pair of bolts and a pair of pins. Part of ...

Embodiment 2

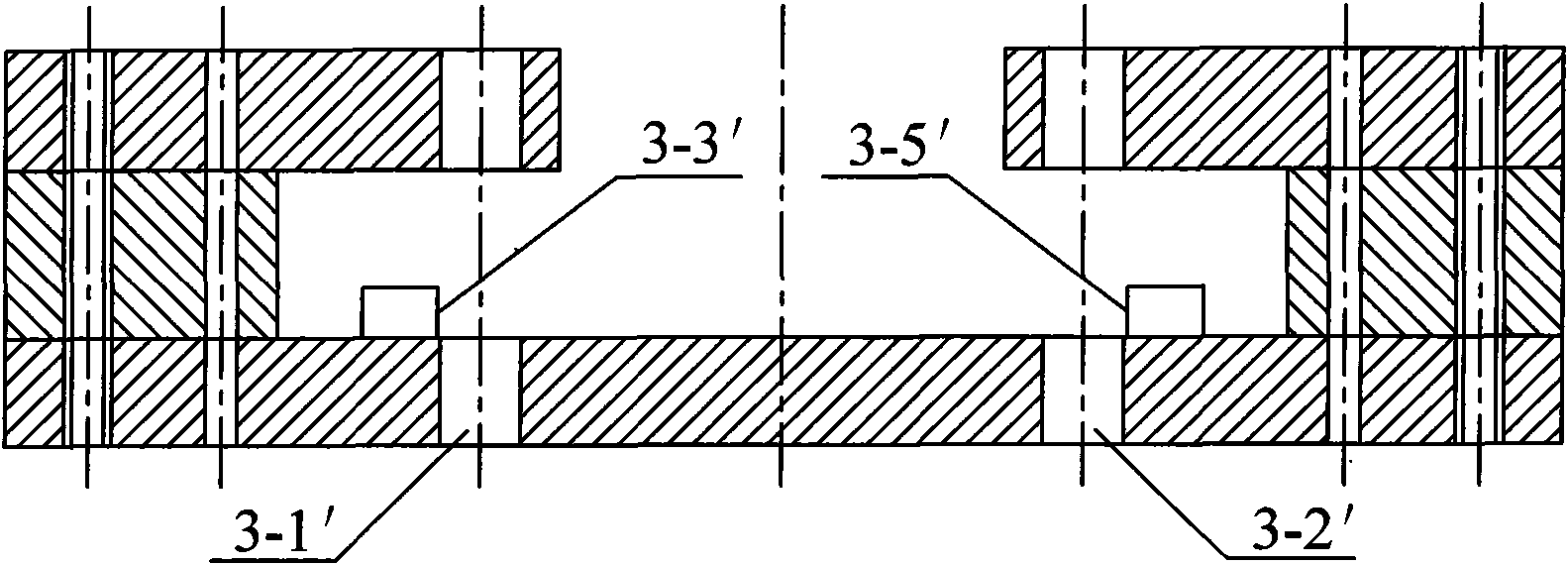

[0024] Such as image 3 and Figure 4 As shown, the structure of the jig in this embodiment is roughly the same as that in Example 1, the difference is that the two positioning pins 3-3' and 3-4' are farther away from the lower die than the hole 3-1' 3. The center line in the width direction is far; the other two positioning pins 3-5' and 3-6' are farther from the center line in the width direction of the lower die 3 than the drill hole 3-2, so as to meet the requirements of processing the rear positioning bead with two positioning holes. Circle requirements.

Embodiment 3

[0026] Such as Figure 5 , Figure 6 and Figure 7 As shown, the structure of the jig in this embodiment is substantially the same as the jig in Embodiment 1, except that the upper mold 4 is an integral structure. Four evenly distributed upper die drilling holes 4-1, 4-2, 4-3 and 4-4 are set in the middle part of the upper die 4. On the lower die 6, four lower die bores 5-1, 5-2, 5-4 corresponding to the above four evenly distributed upper die bores 4-1, 4-2, 4-3 and 4-4 3 and 5-4. In addition, four positioning pins 5-5, 5-6, 5-7 and 5-8 are set on the upper side of the lower mold 5, and the above four positioning pins 5-5, 5-6, 5-7 and 5-8 are distributed between two adjacent lower mold drilling holes.

[0027] The drilling jig in this embodiment is used to process the rear bead ring with four positioning holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com