Construction method of long auger drilling guncreting expanded bore pile

A long-spiral drilling and concrete pouring technology, which is applied to drilling equipment and methods, drill bits, drill pipes, etc., can solve the problems of affecting the bearing capacity of the expanded bottom pile, reducing the stable connection between the expanded bottom pile and the soil, and falling. , to achieve the effect of easy operation, guaranteed bearing capacity and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

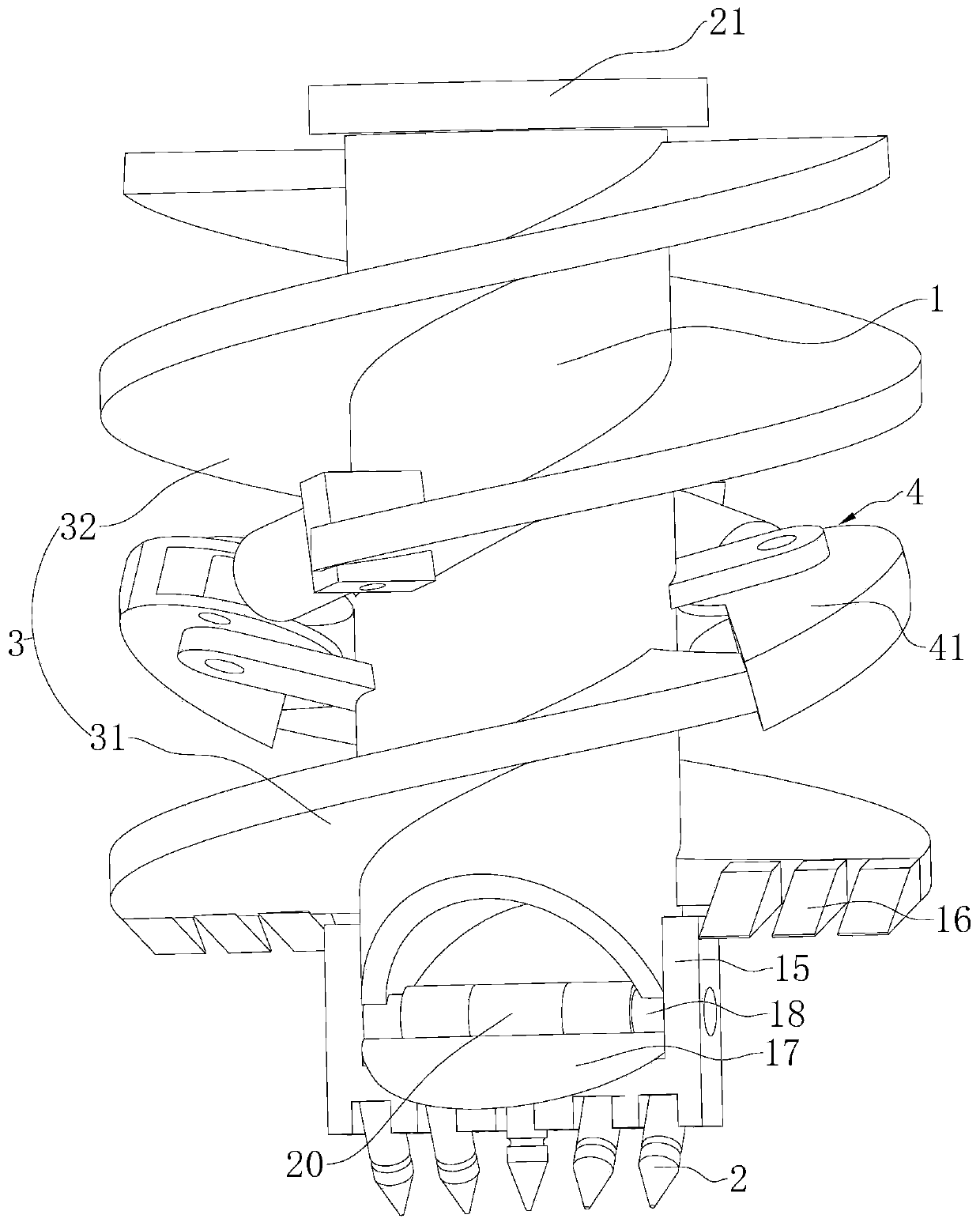

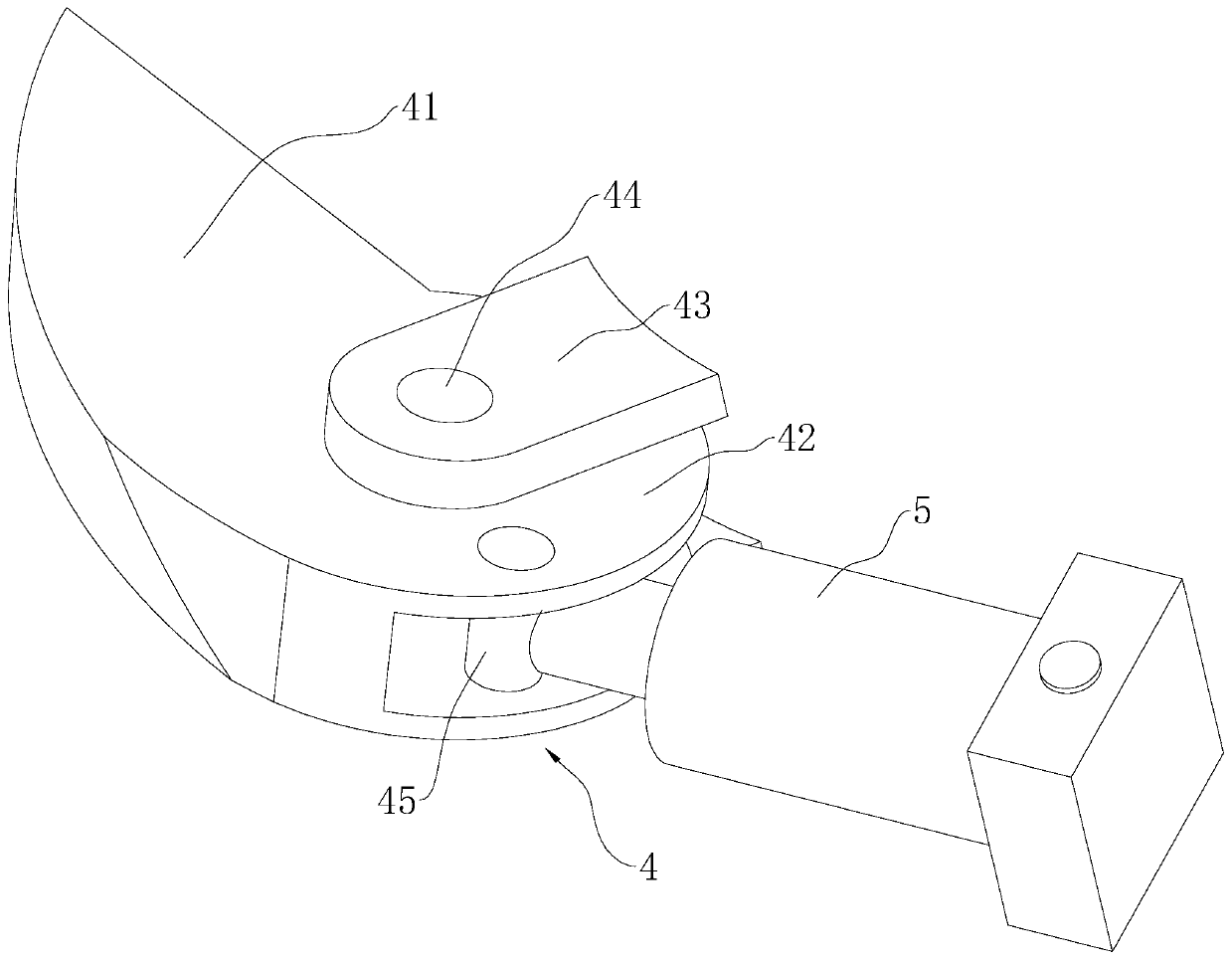

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings.

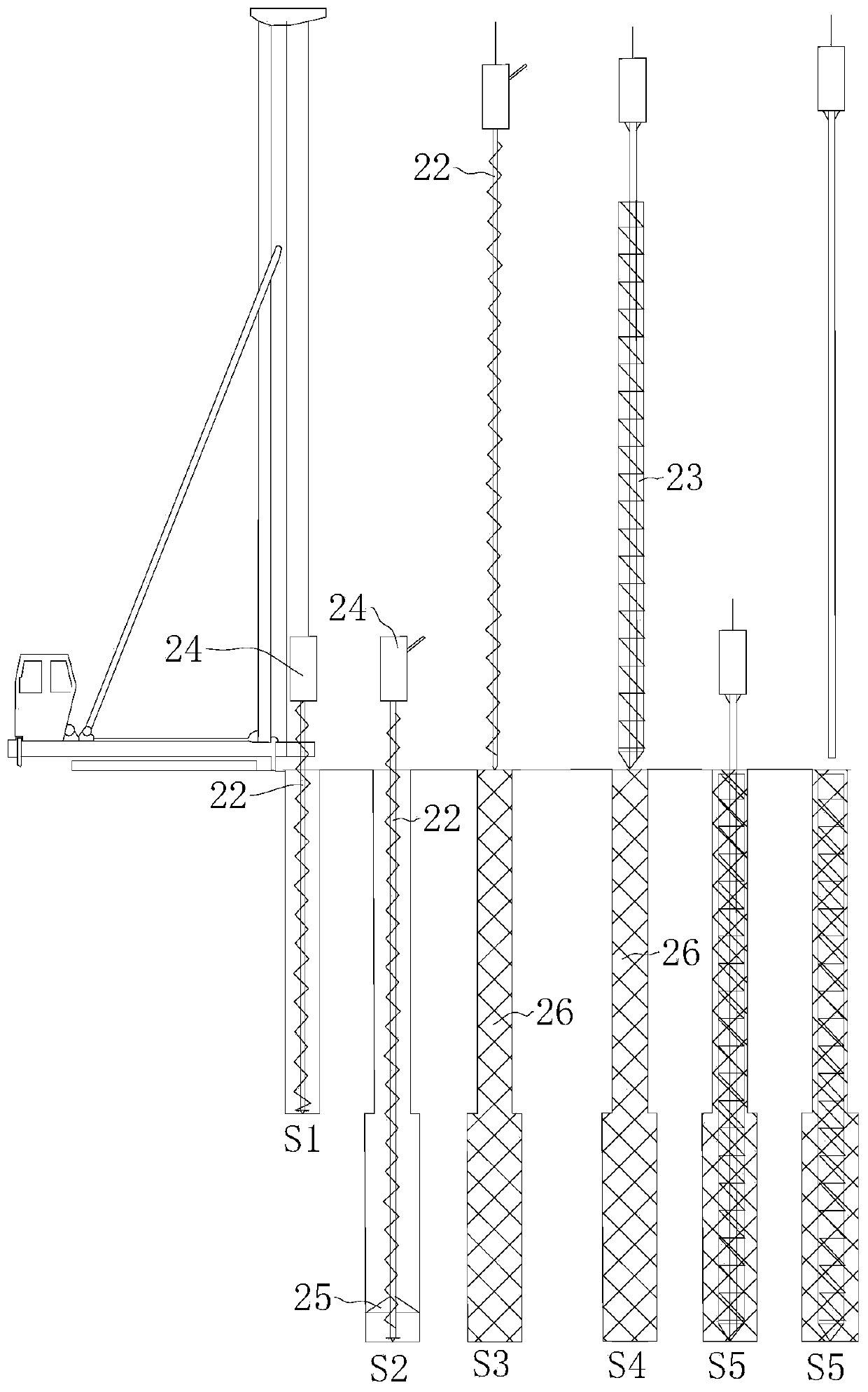

[0059] refer to figure 1 , is a kind of long helical drilling press grouting concrete bottom expansion pile construction method disclosed by the present invention, and its steps are as follows:

[0060] S1, the long screw pile driver is in place, the upper part of the drill pipe 22 is connected with the power head 24, the lower part of the drill pipe 22 is connected with the bottom expansion drill bit 25, and the bottom expansion drill bit 25 is kept closed, and the hole is drilled downward at the predetermined pile position, and continues to drill until The layer where bottom expansion construction is expected to be carried out;

[0061] S2, drill to the pile diameter above the designed pile bottom level, slow down the rotating speed of the drill pipe 22, and at the same time expand the bottom expansion drill bit 25 gradually, and carry out the hole reaming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com