Carrier unbonded steel strand anchor cable

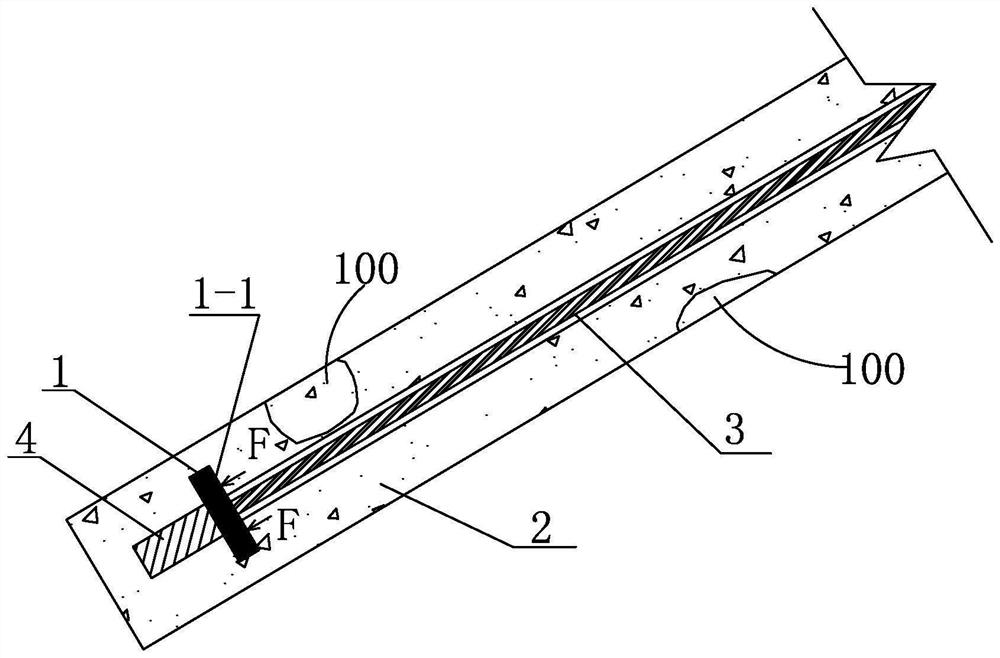

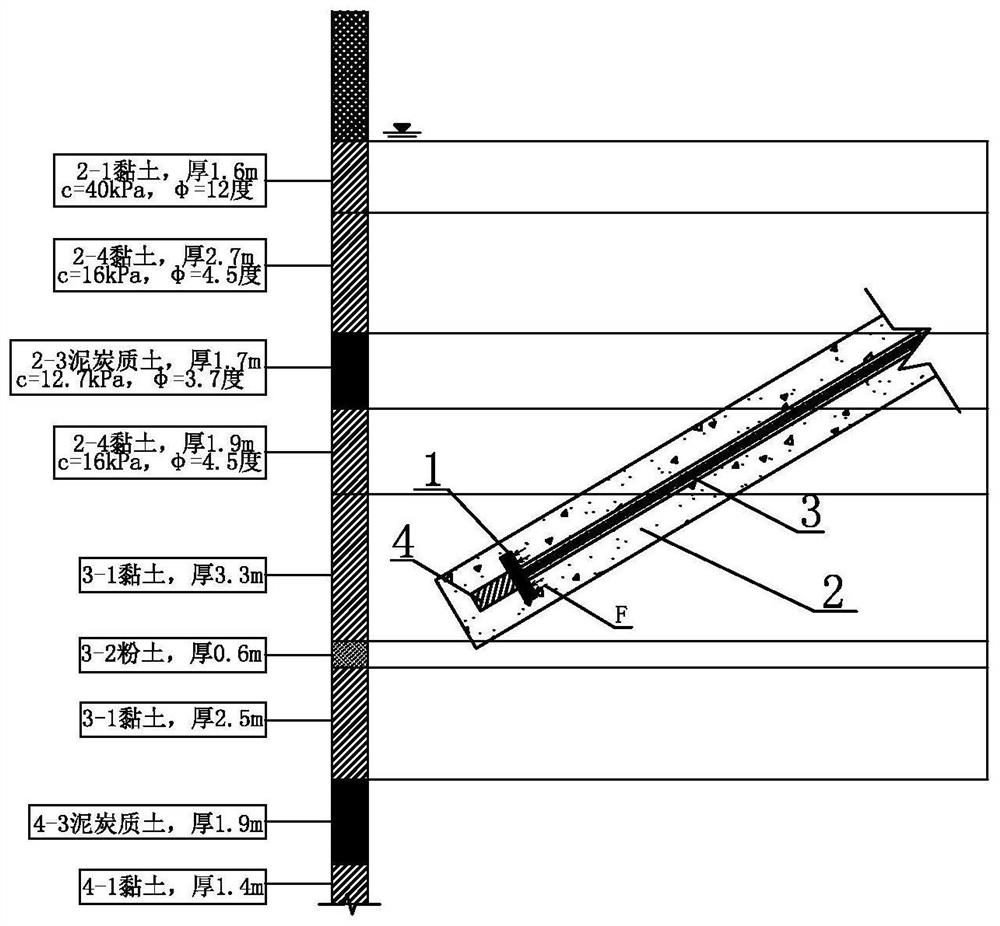

A technology of bearing body and steel strand, which is applied in the direction of basic structure engineering, building, sheet pile wall, etc., can solve the problem that it is difficult to control the bearing plate 1 and lock the anchor 4, and the anchoring force of the anchor cable is not high enough, which affects the resistance of the anchor cable. Pullout force and other issues, to achieve the effect of easy control of construction quality, stress dispersion, and increased pullout resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

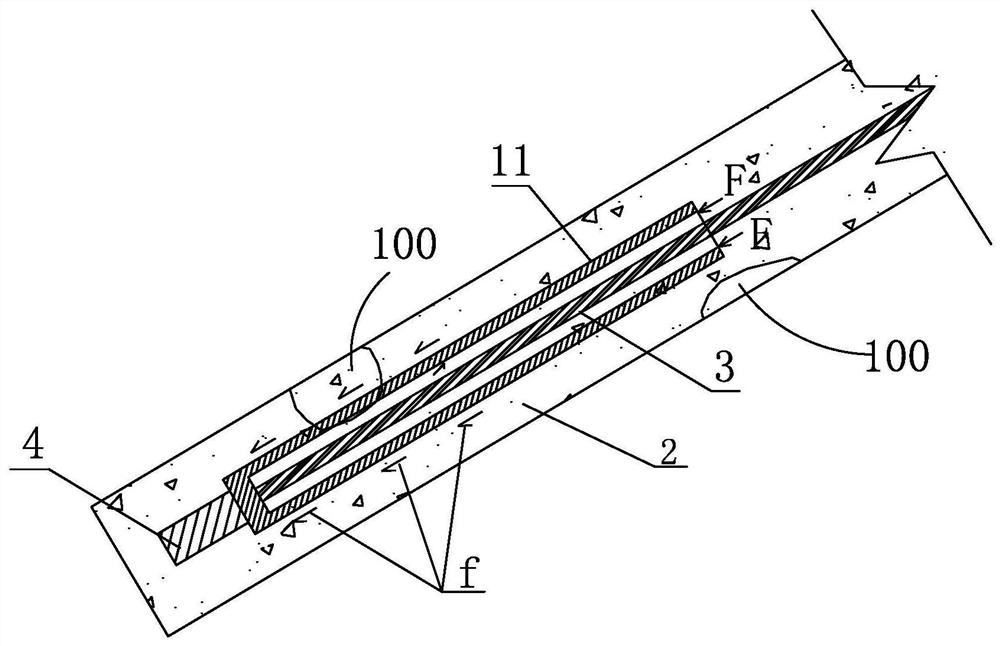

[0032] The carrier of this embodiment has no bonded steel strand anchor cable, such as image 3 As shown, it includes an unbonded steel strand 3 for insertion into a borehole 2 in the ground, a locking anchor 4 and a carrier 11 . In this embodiment, the carrier 11 is a long tubular tube made of glass fiber, and the carrier 11 extends longitudinally along the steel strand 3 into a long sleeve. Of course, in addition to the glass fiber, plastic, steel, Aluminum or other materials. Such as Figure 4 and Figure 5 As shown, one end surface of the glass fiber tube of the carrier 11 and the sleeve are integrally made and provided with a through hole 5 for the steel strand 3 to pass through, and the steel strand 3 penetrates into the glass fiber tube of the carrier 11 and One end of the steel strand 3 passes through the through hole 5 on one end surface of the steel strand 3 and is fixedly connected to the locking anchor 4 , and the locking anchor 4 is attached to one end surface ...

Embodiment 2

[0063] The unbonded steel strand anchor cable of the carrier in this embodiment is a change based on the embodiment, and the difference from Embodiment 1 is that the shape of the carrier 11 changes. The present embodiment non-exhaustively lists four kinds of changes as follows:

[0064] The first variation, such as Figure 7 As shown, the cross section of the carrier 11 is hexagonal.

[0065] The second variation, such as Figure 8 As shown, the cross section of the carrier 11 is gear-shaped.

[0066] A third variation, such as Figure 9 As shown, the outer surface of the carrier 11 is in the shape of a helical tooth.

[0067] A fourth variation, such as Figure 10 and Figure 11 As shown, holes 8 are opened on the wall of the elongated sleeve of the carrier 11, and the holes 8 are not only arranged at intervals along the circumference of the elongated sleeve, but also arranged at intervals along the length of the elongated sleeve.

[0068] Of course, in addition to the...

Embodiment 3

[0070] The unbonded steel strand anchor cable of the carrier of the present embodiment is a change on the basis of the embodiment. The difference from Embodiment 1 is that a plurality of carriers 11 are sequentially connected to the steel strands along the longitudinal direction of the steel strands 3. on line 3. Such as Figure 12 As shown, the glass fiber sleeves formed by three carriers 11 are sequentially sleeved on the steel strands 3 . Of course, there can also be two or more carriers 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com