Microporous carbon aerogel and preparation method thereof

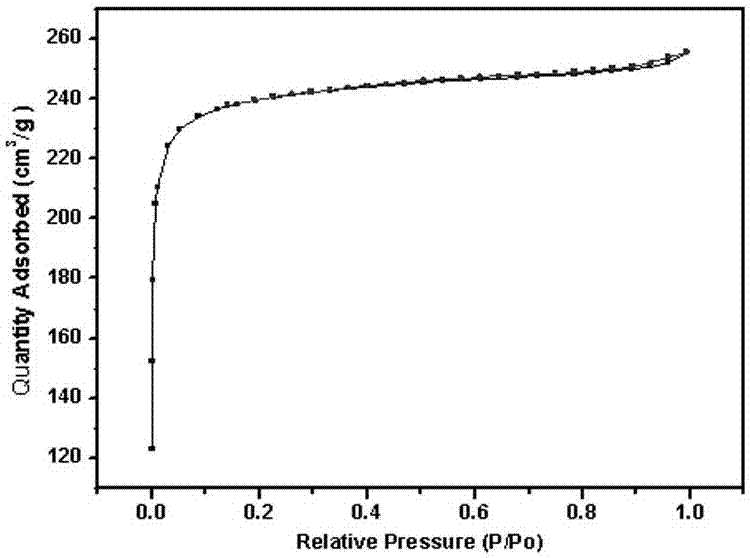

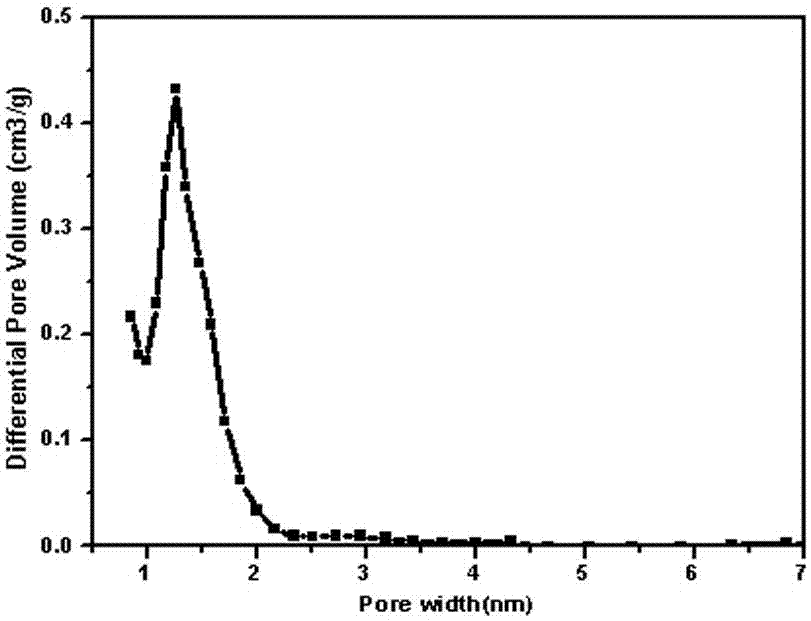

A carbon aerogel and aerogel technology, applied in the field of microporous carbon aerogel and its preparation, can solve problems such as unfavorable cost reduction, unfriendly environment, etc., and achieve a narrow pore size distribution range, environmental friendliness, and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Step 1: Organic Wet Gel Preparation

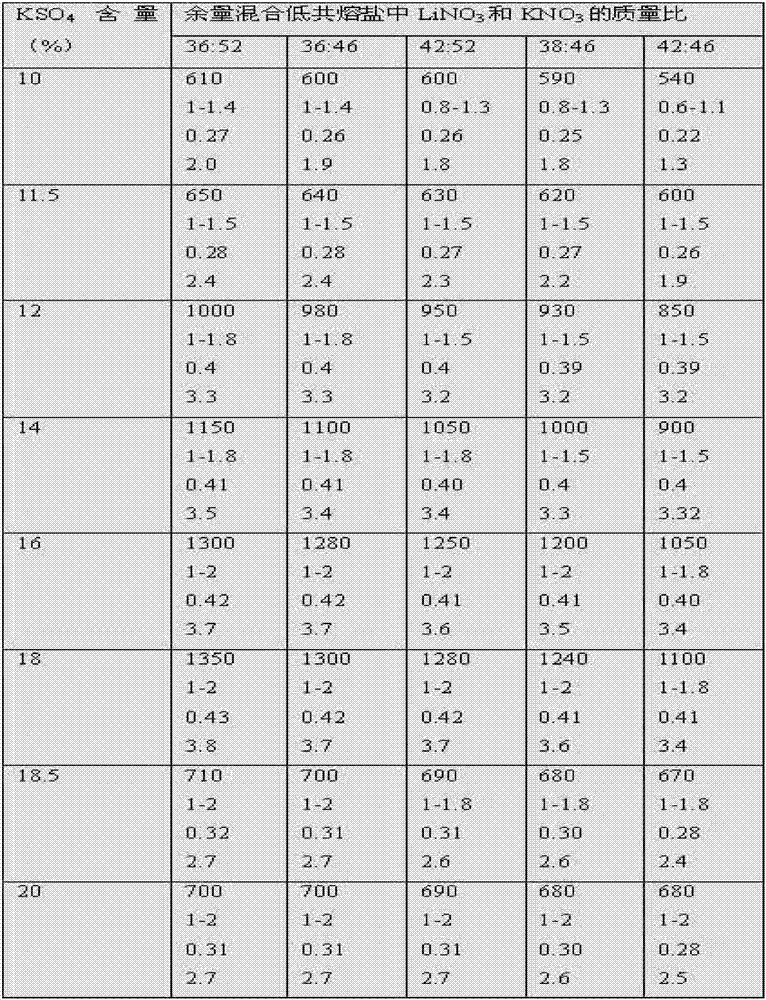

[0059] Mix polyhydroxybenzene and formaldehyde at a molar ratio of 1:2, add deionized water to prepare a reaction solution with a mass fraction of 40%, and then add 38% LiNO 3 , 46% KNO 3 and 16%K 2 SO 4 The mixed eutectic salt, the addition of the mixed eutectic salt is 20% of the total mass of polyhydroxybenzene and formaldehyde, the reaction solution is evenly mixed and then sealed, and kept at 50°C for full reaction for 3 days to obtain resorcinol- Phloroglucinol-formaldehyde organic wet gel, the polyhydroxybenzene is a mixture of phloroglucinol and resorcinol in a molar ratio of 7:1;

[0060] Step 2: Freeze drying

[0061] Put the organic wet gel prepared in step 1 directly into a freeze-drying box, and dry it at -80±5°C for one day to obtain an organic aerogel;

[0062] Step 3: High temperature carbonization

[0063] The organic airgel obtained in step 2 was carbonized under vacuum conditions, and N was continuously fed ...

Embodiment 2

[0068] Step 1: Organic Wet Gel Preparation

[0069] Mix polyhydroxybenzene and formaldehyde at a molar ratio of 1:2, add deionized water to prepare a reaction solution with a mass fraction of 40%, and then add 36% LiNO 3 , 52% KNO 3 and 12%K 2 SO 4 The mixed eutectic salt, the addition of the mixed eutectic salt is 20% of the total mass of polyhydroxybenzene and formaldehyde, the reaction solution is evenly mixed and then sealed, and kept at 50°C for full reaction for 3 days to obtain resorcinol- Phloroglucinol-formaldehyde organic wet gel, the polyhydroxybenzene is a mixture of phloroglucinol and resorcinol in a molar ratio of 7:1;

[0070] Step 2: Freeze drying

[0071] Put the organic wet gel prepared in step 1 directly into a freeze-drying box, and dry it at -80±5°C for one day to obtain an organic aerogel;

[0072] Step 3: High temperature carbonization

[0073] The organic airgel obtained in step 2 was carbonized under vacuum conditions, and N was continuously fed ...

Embodiment 3

[0078] Step 1: Organic Wet Gel Preparation

[0079] Mix polyhydroxybenzene and formaldehyde at a molar ratio of 1:2, add deionized water to prepare a reaction solution with a mass fraction of 40%, and then add 42% LiNO 3 , 46% KNO 3 and 12%K 2 SO 4 The mixed eutectic salt, the addition of the mixed eutectic salt is 20% of the total mass of polyhydroxybenzene and formaldehyde, the reaction solution is evenly mixed and then sealed, and kept at 50°C for full reaction for 3 days to obtain resorcinol- Phloroglucinol-formaldehyde organic wet gel, the polyhydroxybenzene is a mixture of phloroglucinol and resorcinol in a molar ratio of 7:1;

[0080] Step 2: Freeze drying

[0081] Put the organic wet gel prepared in step 1 directly into a freeze-drying box, and dry it at -80±5°C for one day to obtain an organic aerogel;

[0082] Step 3: High temperature carbonization

[0083] The organic airgel obtained in step 2 was carbonized under vacuum conditions, and N was continuously fed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore size distribution | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com