Drying method of polyglycolide warp knitted support net for artificial skin

A technology of polyglycolide and artificial skin, which is applied in the direction of drying solid materials, heating to dry solid materials, and non-heating to dry solid materials, etc., which can solve the problems of loss of mechanical properties and achieve the effect of maintaining tensile fracture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

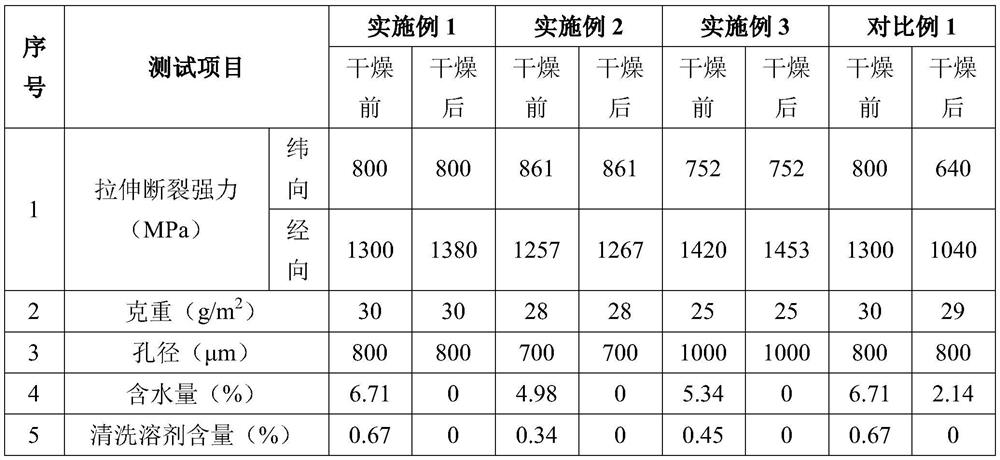

Examples

Embodiment 1

[0025] The present embodiment provides a drying method for a polyglycolide warp-knitted support web for artificial skin, which specifically includes pre-drying, deep drying and fabric stress relaxation in sequence.

[0026] The pre-drying process is: placing the cleaned and dried polyglycolide warp knitted support mesh in a vacuum drying box A, the vacuum drying box A is connected with a water circulation vacuum pump, the temperature of the vacuum drying box A is set to 25 ° C, and the water circulation is turned on at the same time. The vacuum pump continues to run, so that the polyglycolide warp knitted support mesh is dried for 1 hour under the condition of vacuum degree of 390Pa, then the water circulation vacuum pump is turned off, and air is slowly introduced to make the vacuum drying box A return to normal pressure.

[0027] The steps of the deep drying process are:

[0028] (1) Take out the polyglycolide warp-knitted support net from vacuum drying oven A, place it in v...

Embodiment 2

[0036] The present embodiment provides a drying method for a polyglycolide warp-knitted support web for artificial skin, which specifically includes pre-drying, deep drying and fabric stress relaxation in sequence.

[0037] The pre-drying process is: placing the cleaned and dried polyglycolide warp knitted support net in a vacuum drying box A, the vacuum drying box A is connected with a water circulation vacuum pump, the temperature of the vacuum drying box A is set to 30 ° C, and the water circulation is turned on at the same time. The vacuum pump continues to run, so that the polyglycolide warp knitted support mesh is dried for 1.5 hours under the condition of vacuum degree of 350Pa, then the water circulation vacuum pump is turned off, and air is slowly introduced to make the vacuum drying box A return to normal pressure.

[0038] The steps of the deep drying process are:

[0039] (1) Take out the polyglycolide warp-knitted support net from the vacuum drying oven A, and pla...

Embodiment 3

[0047] The present embodiment provides a drying method for a polyglycolide warp-knitted support web for artificial skin, which specifically includes pre-drying, deep drying and fabric stress relaxation in sequence.

[0048] The pre-drying process is as follows: place the cleaned and dried polyglycolide warp knitted support mesh in a vacuum drying box A, the vacuum drying box A is connected with a water circulation vacuum pump, the temperature of the vacuum drying box A is set to 28 ° C, and the water circulation is turned on at the same time. The vacuum pump continues to run, so that the polyglycolide warp knitted support mesh is dried for 1.8 hours under the condition of vacuum degree of 380Pa, then the water circulation vacuum pump is turned off, and air is slowly introduced to make the vacuum drying box A return to normal pressure.

[0049] The steps of the deep drying process are:

[0050] (1) The polyglycolide warp-knitted support net is taken out from the vacuum drying b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com