Manufacturing method for nickel-copper end sockets

A nickel-copper alloy and manufacturing method technology, applied in the field of nickel-copper alloy head manufacturing, can solve the problems that the workpiece cannot meet technical requirements, difficult forming and processing, poor plastic deformation, etc., and achieve reasonable distribution of metal streamlines and thermal processing system. Feasible, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

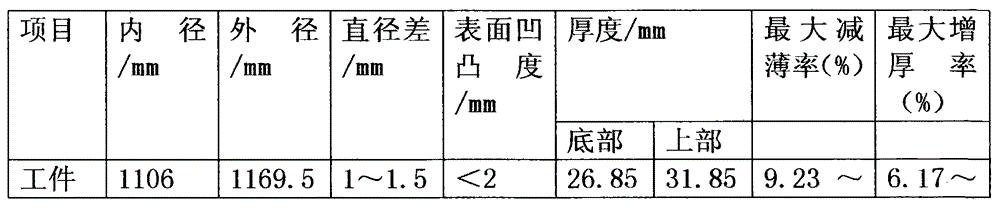

[0024] The present invention is applied to the NCu30 nickel-copper alloy plate head of ¢1100 / 30mm specification, and the specific implementation method is as follows:

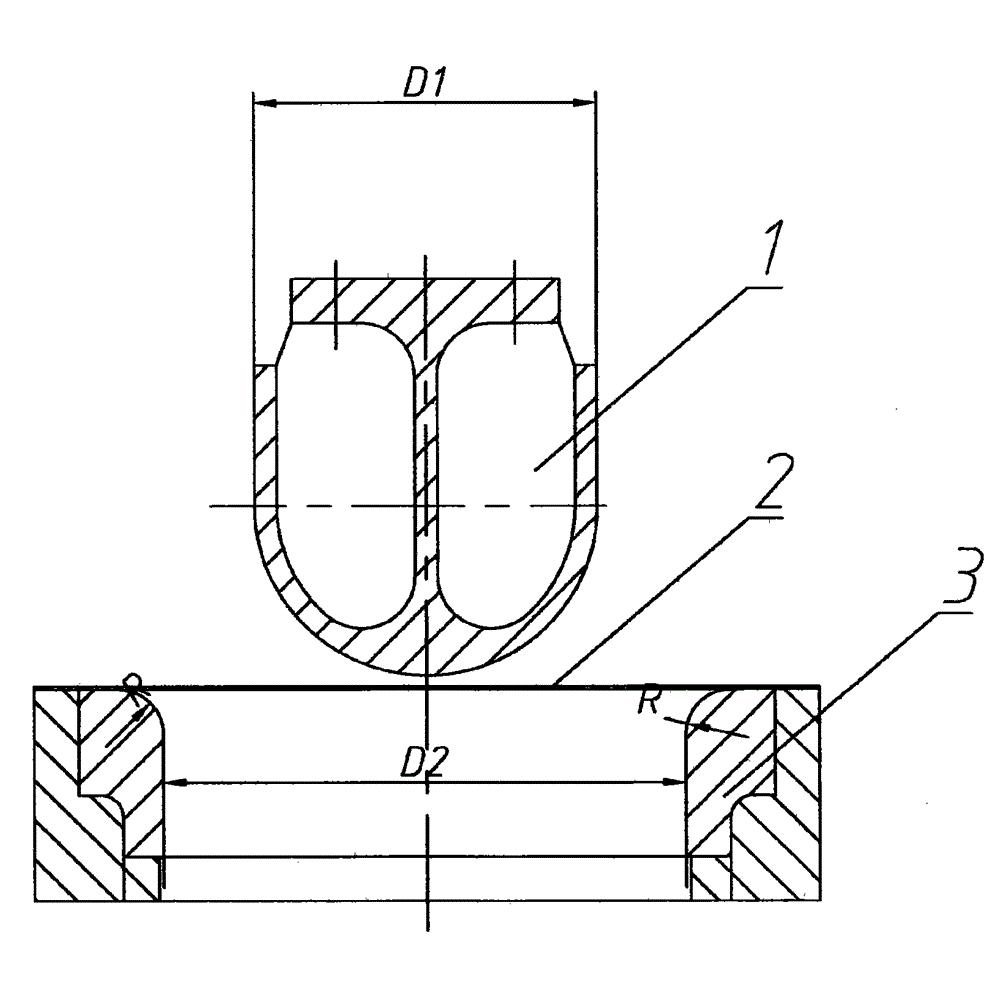

[0025] (1), mold design: the diameter of the head is 1100mm, the wall thickness is 30mm, and the diameter D of the upper mold pressure head is calculated according to the formula of the technical plan 1 Take 1106mm, the diameter of the outlet of the lower die pull ring is D 2 Take 1170mm, take the gap Z between the upper and lower molds as 31.8mm, and take the fillet R of the lower mold pull ring as 75mm;

[0026] (2), mold grinding and cleaning: before pressing, the mold is polished and cleaned;

[0027] (3) Pre-treatment of the billet: grinding and cleaning the edge of the billet to remove oxidation and peripheral burrs generated during flame cutting around the billet; before stamping the billet, the edge of the surface is beveled, the beveling angle is 4°, and the edge is cut off at most The thickness is 3...

Embodiment 2

[0042] The present invention is applied to the NCu30 nickel-copper alloy plate head of ¢2400 / 30mm specification, and the specific implementation method is as follows:

[0043] (1) Mold design: the diameter of the head is 2400mm, the wall thickness is 30mm, and the diameter D of the upper mold head is calculated according to the formula of the technical plan 1 Take 2417mm, the diameter of the outlet of the lower die pull ring is D 2 Take 2481mm, take the gap Z between the upper and lower molds as 31.8mm, and take the fillet R of the lower mold pull ring as 105mm;

[0044] (2), mold grinding and cleaning: before pressing, the mold is polished and cleaned;

[0045] (3) Pre-treatment of the billet: grinding and cleaning the edge of the billet to remove oxidation and peripheral burrs generated during flame cutting around the billet; before stamping the billet, the edge of the surface is beveled, the beveling angle is 5°, and the edge is cut off at most The thickness is 3mm; befor...

Embodiment 3

[0055] The present invention is applied to the NCu30 nickel-copper alloy plate head of ¢1800 / 30mm specification, and the specific implementation method is as follows:

[0056] (1), mold design: the diameter of the head is 1800mm, the wall thickness is 30mm, and the diameter D of the upper mold pressure head is calculated according to the formula of the technical plan 1 Take 1811mm, the diameter of the outlet of the lower die pull ring is D 2 Take 1875mm, the gap Z between the upper and lower molds is 31.8mm, and the rounded corner R of the lower mold pull ring is 90mm;

[0057] (2), mold grinding and cleaning: before pressing, the mold is polished and cleaned;

[0058] (3) Pre-processing of the billet: grinding and cleaning the edge of the billet to remove oxidation and peripheral burrs generated during flame cutting around the billet; before stamping the billet, the edge of the surface is beveled, the beveling angle is 4.5°, and the edge is cut off at most The thickness is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com