Punching die for producing hard alloy saw-tooth tool bit

A technology of cemented carbide and stamping dies, which is applied in the field of stamping dies and stamping dies for the production of cemented carbide sawtooth cutter heads. It can solve the problems of affecting the quality of product processing, unstable fixing of the lower punch, and unstable operation of the mold. Achieve the effects of simple structure, saving maintenance cost and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

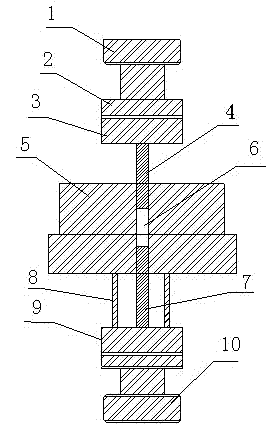

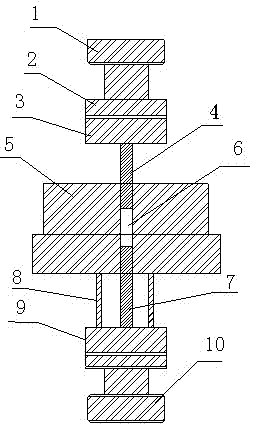

[0012] see figure 1 , the present embodiment is a stamping die for producing cemented carbide sawtooth cutter heads, including a die body 5, an upper punch seat 1, a lower punch seat 10, and upper and lower punches respectively installed on the upper and lower punch seats . Between the upper punch seat 1 and the upper punch 2 and between the lower punch seat 10 and the lower punch 7 are respectively provided with an upper fixed piece 3 and a lower fixed piece 9, and the upper fixed piece 3 is sleeved with an upper punch 4 , The lower punch 7 is sleeved on the lower fixing piece 10 .

[0013] The two sides of the lower punch 7 are also sleeved with ring pads 8 , and the ring pads 8 are placed on the upper end surface of the lower fixing piece 9 . The mold body 5 is placed on the upper end surface of the annular spacer 8 , the upper end surface of the lower punch 7 and the mold body 5 form a mold cavity 6 , and the upper punch 2 is correspondingly arranged above the mold cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com