Glass plate perforating device

A punching device and plate technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of low punching efficiency, affecting punching stability, and clamping parts stuck on the support arm, etc., to achieve High efficiency, stable stamping process, avoiding stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through specific implementations:

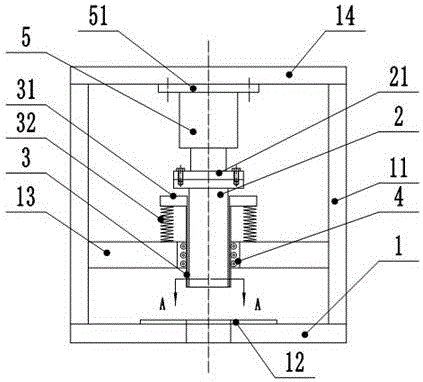

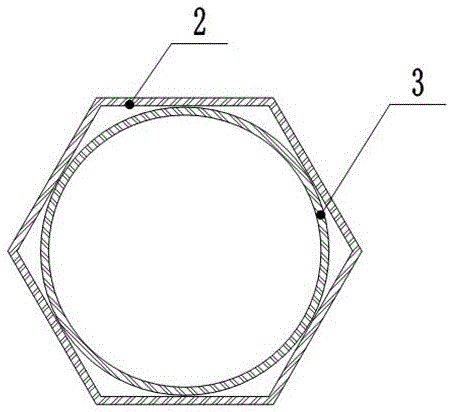

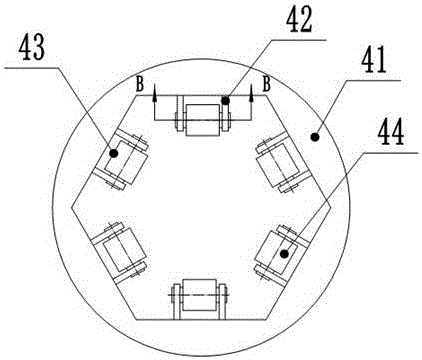

[0019] The reference signs in the drawings of the specification include: base 1, support arm 11, working platform 12, middle beam 13, upper beam 14, round punch 2, flange 21, hexagonal punch 3, mounting plate 31, The spring 32, the sliding sleeve 4, the sleeve 41, the mounting frame 42, the belt 43, the pulley 44, the pushing cylinder 5, and the connecting plate 51.

[0020] The embodiment is basically as attached figure 1 And figure 2 Shown:

[0021] The glass sheet punching device in this solution includes a support, and the support includes a work platform 12 on which stamping parts are placed. The two sides of the work platform 12 are welded with longitudinal support arms 11, and the two support arms 11 are transversely A middle beam 13 is connected, a through hole is machined on the middle beam 13, a sliding sleeve 4 is installed in the through hole, and a punch is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com