Manufacturing method for nickel composite board end sockets

A manufacturing method and composite plate technology, which is applied in the field of nickel composite plate head manufacturing, can solve the problems that the workpiece cannot meet the technical requirements, difficult forming and processing, and poor plastic deformation, so as to achieve reasonable distribution of metal streamlines and feasible thermal processing system , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

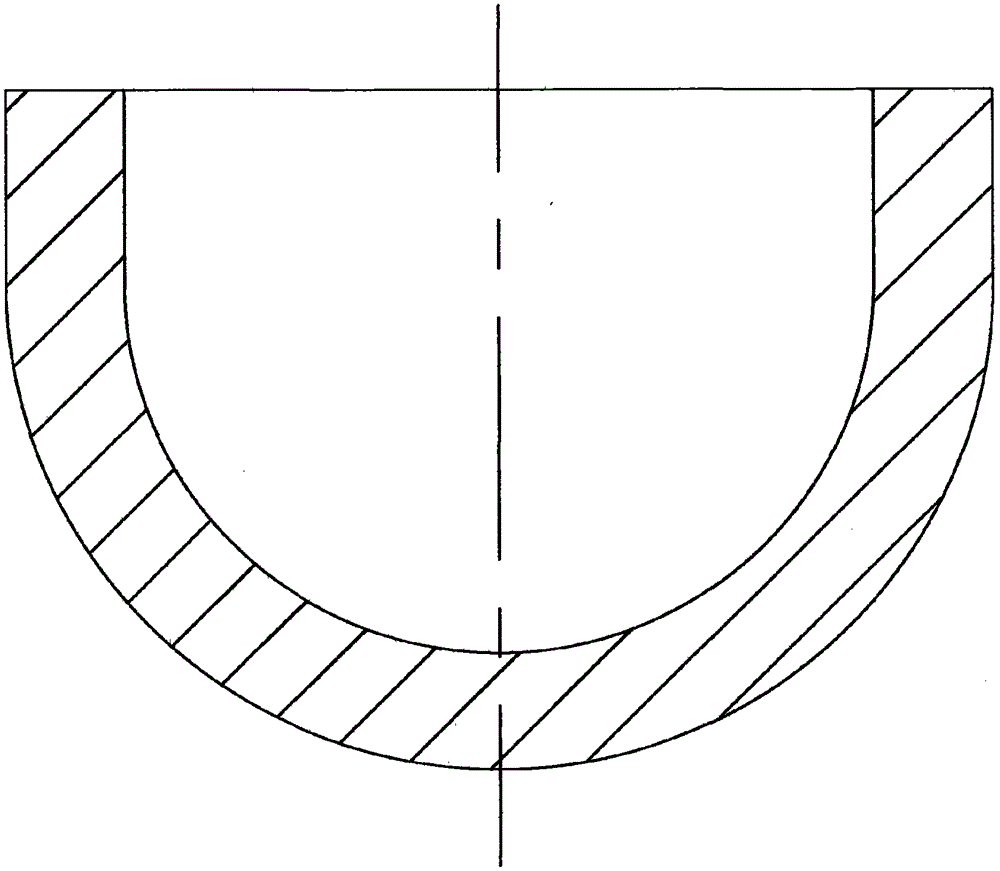

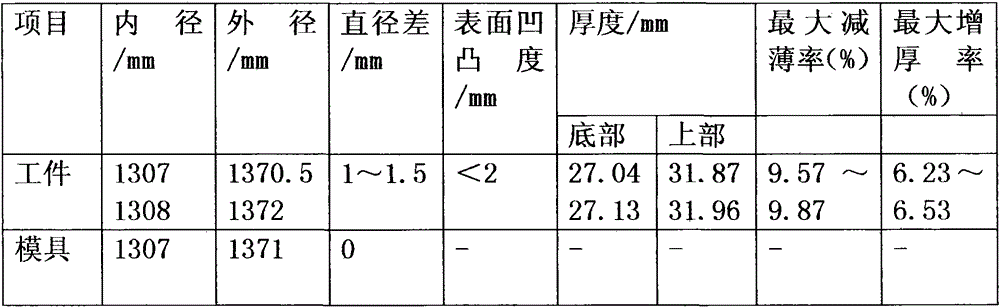

[0027] The present invention is applied to the head of N02201 / Q345R nickel composite plate with the specification of ¢1300 / 30mm, and the specific implementation method is as follows:

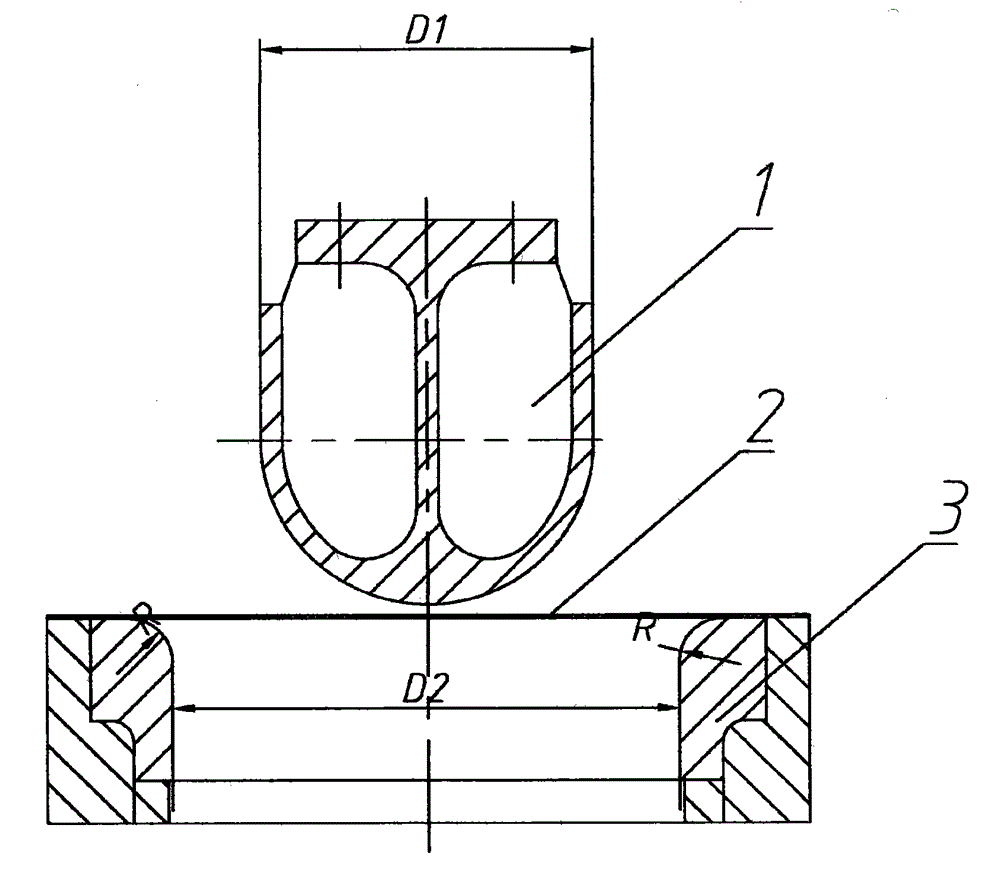

[0028] (1), mold design: the diameter of the head is 1300mm, the wall thickness is 30mm, and the diameter D of the upper mold pressure head is calculated according to the formula of the technical plan 1 Take 1307mm, the diameter of the outlet of the lower die pull ring is D 2 Take 1371mm, take the gap Z between the upper and lower molds as 31.8mm, and take the fillet R of the lower mold pull ring as 75mm;

[0029] (2) Splicing composite panels: Splice the required nickel composite panels, and the spliced panels are used as the blank for forming the head of the nickel composite panels. The spliced panels must be spot-welded and pasted on the weld seam, and the pasting strips should be left blank than the weld seam The width is narrower than 3mm, and the cladding of the weld seam is completel...

Embodiment 2

[0047] The present invention is applied to the N02201 / Q345R nickel composite plate head of ¢3400 / 30mm specification, and the specific implementation method is as follows:

[0048] (1), mold design: the diameter of the head is 3400mm, the wall thickness is 30mm, and the diameter D of the upper mold pressure head is calculated according to the formula of the technical plan 1 Take 3424mm, the diameter of the outlet of the lower die pull ring is D 2 Take 3488mm, take the gap Z between the upper and lower molds as 31.8mm, and take the fillet R of the lower mold pull ring as 105mm;

[0049] (2) Splicing composite panels: Splice the required nickel composite panels, and the spliced panels are used as the blank for forming the head of the nickel composite panels. The spliced panels must be spot-welded and pasted on the weld seam, and the pasting strips should be left blank than the weld seam The width is narrower by 4mm, and the cladding of the weld seam is completely welded;

...

Embodiment 3

[0063] The present invention is applied to the head of N02201 / Q345R nickel composite plate with the specification of ¢2200 / 30mm, and the specific implementation method is as follows:

[0064] (1), mold design: the diameter of the head is 2200mm, the wall thickness is 30mm, and the diameter D of the upper mold pressure head is calculated according to the formula of the technical plan 1 Take 2215mm, the diameter of the outlet of the lower die pull ring is D 2 Take 2279mm, take the gap Z between the upper and lower molds as 31.8mm, and take the fillet R of the lower mold pull ring as 90mm;

[0065] (2) Splicing composite panels: Splice the required nickel composite panels, and the spliced panels are used as the blank for forming the head of the nickel composite panels. The spliced panels must be spot-welded and pasted on the weld seam, and the pasting strips should be left blank than the weld seam The width is narrower than 3.5mm, and the cladding of the weld seam is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com