Planar-type punching machine with five-guide-rod structure

A technology of gantry and guide rods, which is applied in the direction of presses and manufacturing tools, can solve the problems of uneven force on sliders and molds, affecting the quality of stamping products, and uneven force, so as to overcome instability and deformation of equipment parts Problems, reasonable structural design, and stable stamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

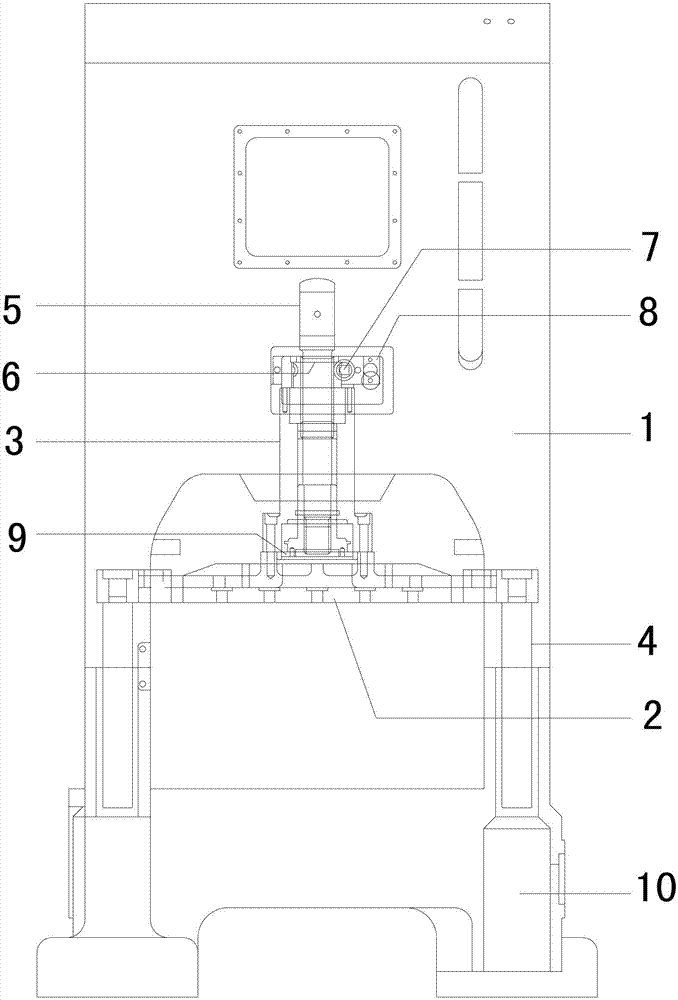

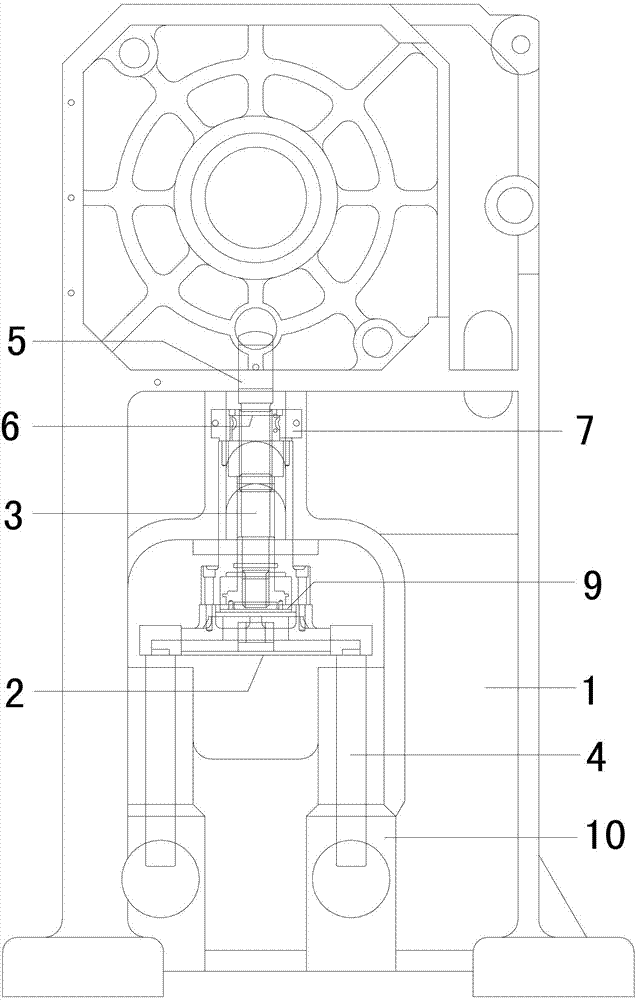

[0015] combine figure 1 , figure 2 As shown, the bed 1 of the present invention is equipped with a slide block 2 thereon, and a steel pipe 3 is fixed above the slide block 2 at the center position above it. The steel pipe 3 is embedded with a piston 9 at the junction with the slide block 2. An adjustment screw 5 is installed above it, and a transmission device composed of a worm gear 6 and a worm 7 meshing with each other is also provided between the steel pipe 3 and the adjustment screw 5, and the transmission device is installed on the steel pipe 3 through a worm gear fixing seat 8. superior.

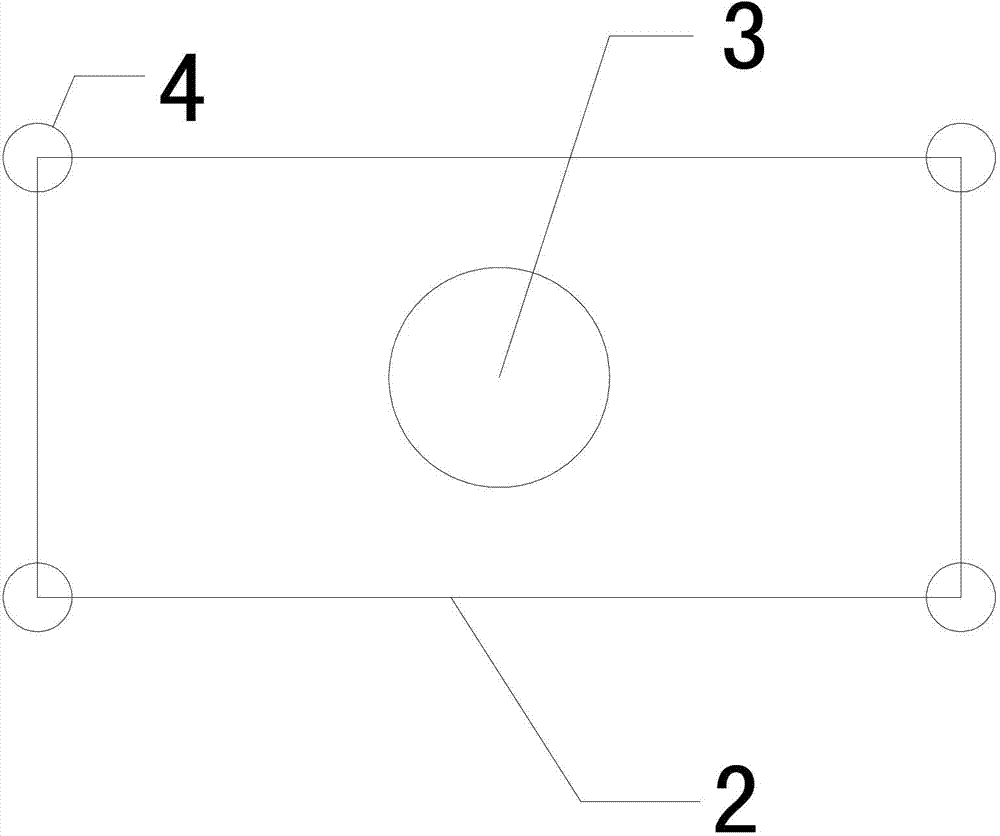

[0016] The bottom of the slider 2 holds a guide post 4 at the corners of the four sides, and the bottom end of each guide post is respectively sleeved in the corresponding guide sleeve 10, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com