Hot powder splashing prevention device for dredging kiln

A splashing device and heat protection technology, which is applied in the field of steelmaking lime roasting, to prevent spraying and ensure personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

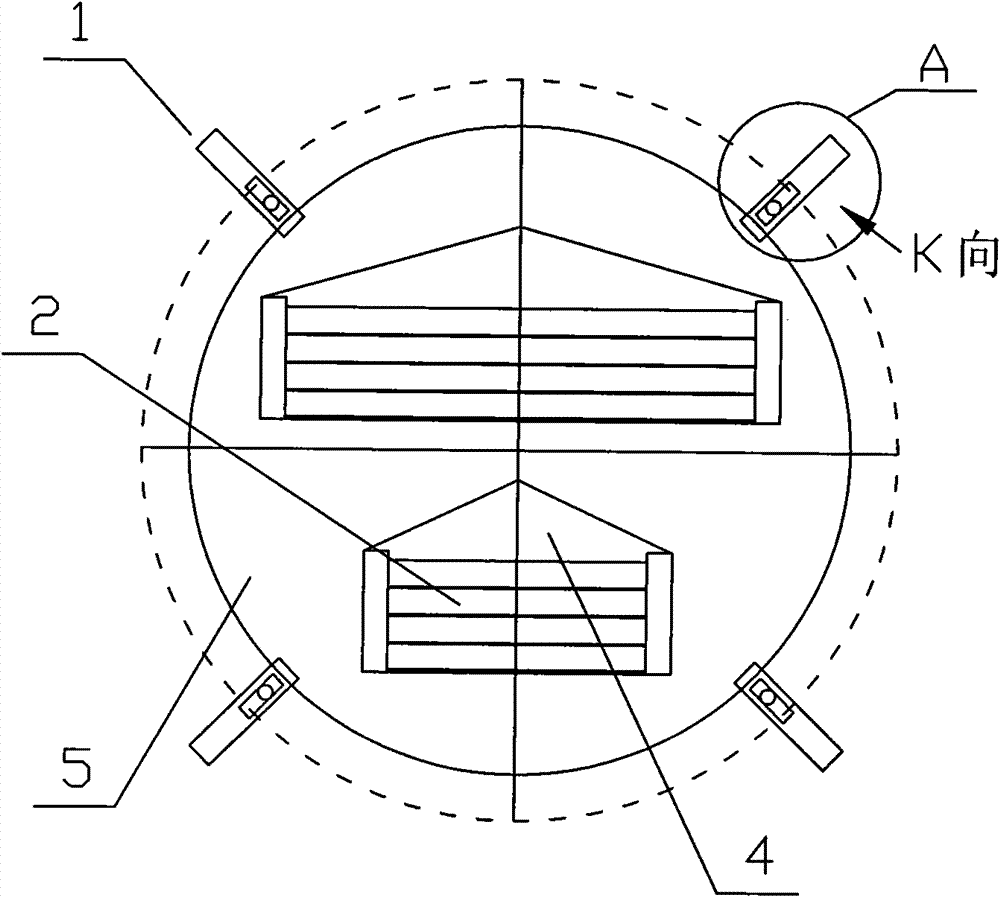

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

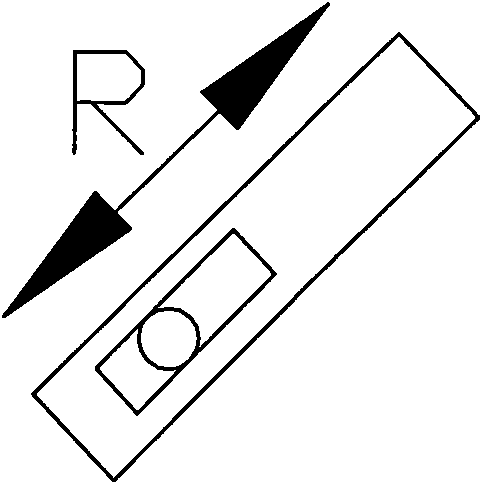

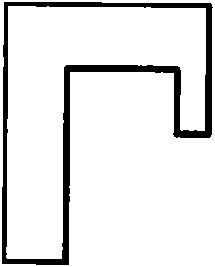

[0022] like figure 1 and Figure 4 As shown, the heat-proof powder splashing device for the kiln of the present invention includes a circular bottom plate 5, four clamping feet 1 positioned at the edge of the bottom plate 5, and the bottom plate 5 is provided with two through-kiln holes 4, each The upper part of each kiln hole 4 is triangular, and the lower part is rectangular. The outside of each through kiln hole 4 is equipped with a detachable baffle plate 2, and the inner side of the bottom plate 5 is provided with a curtain 3 covering the through kiln hole 4. The plate 2 is made of a plurality of horizontally stacked steel pipes, and the curtain 3 is made of a plurality of vertically suspended chains, and can be multilayer chains such as three layers, such as image 3 and figure 2 As shown, the clip 1 is sickle-shaped, and the clip 1 and the bottom plate 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com