Single-motor bilateral-drive energy-saving chain type pumping unit

A dual-side drive, energy-saving technology, applied in the fields of production fluids, wellbore/well components, and earth-moving drilling, etc., can solve the problems that the counterweight cannot be quickly adjusted, the stroke is invariable, and the energy consumption is high, reducing energy consumption, Realize the effect of good stroke and synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

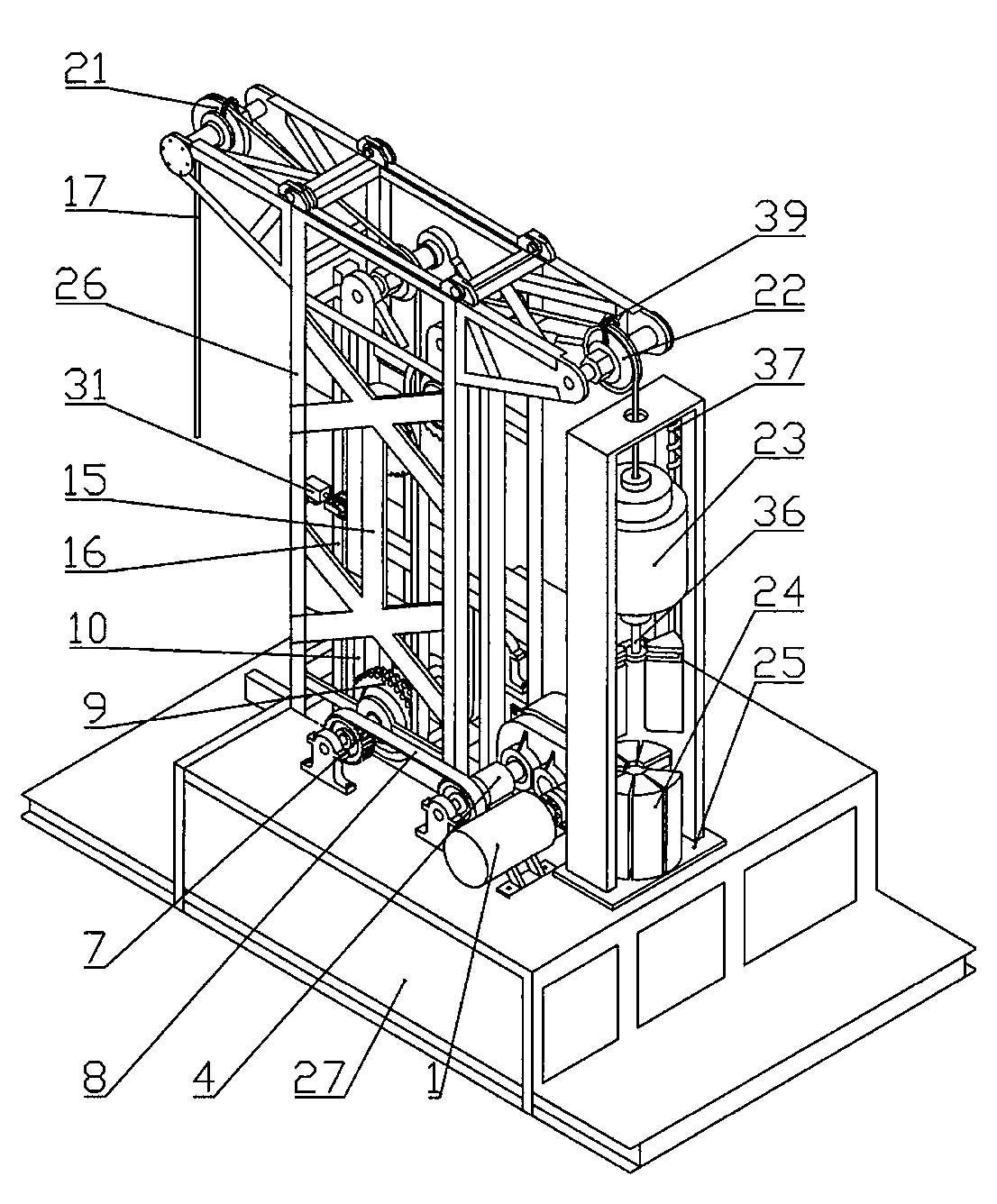

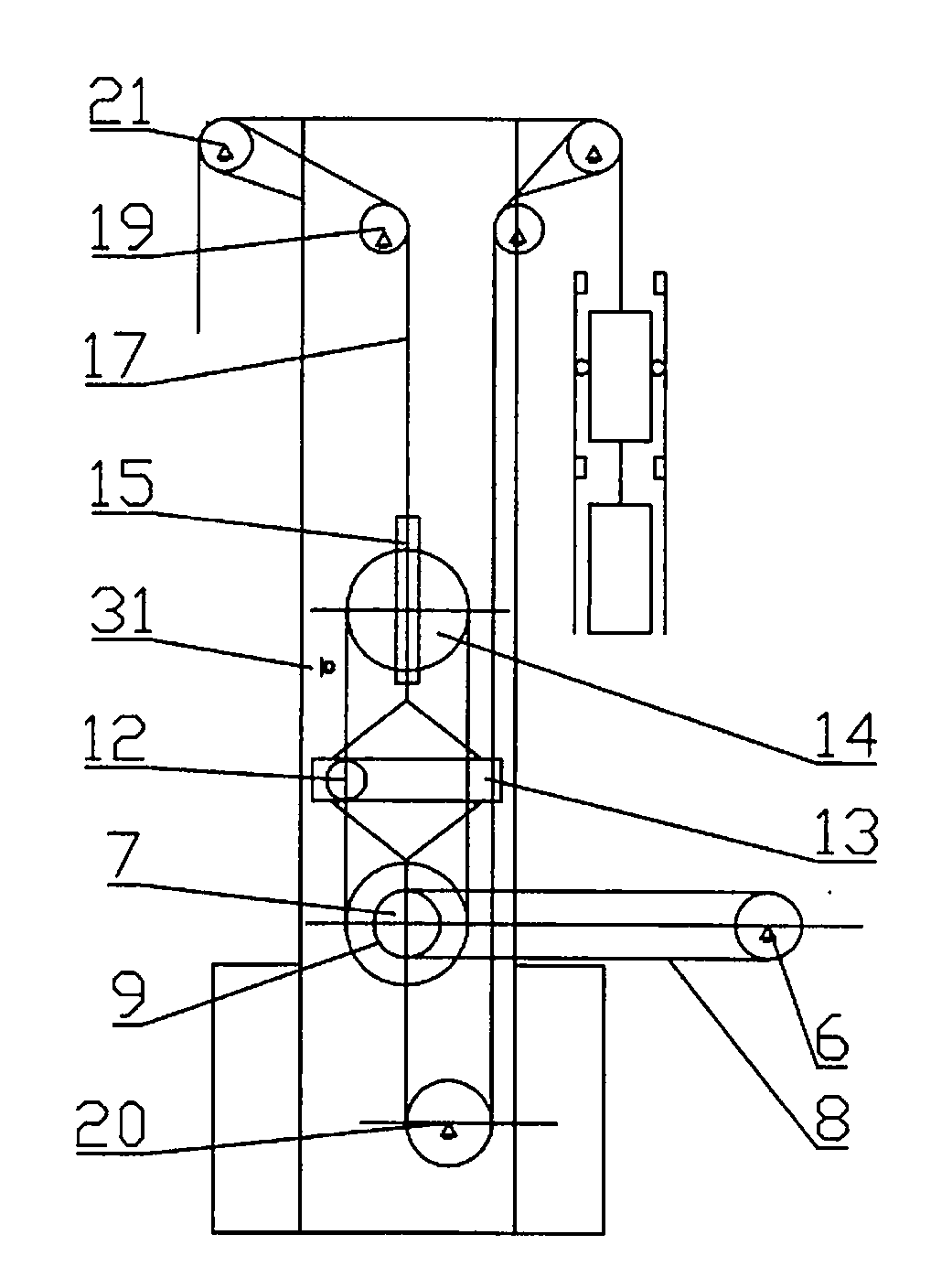

[0030] refer to figure 1 , the present invention is composed of a supporting part, a transmission part and a counterweight adjusting part;

[0031] participate figure 1 and figure 2 , the supporting part includes a base 27 , a main truss 26 and a front and rear bracket 28 .

[0032] The base 27 is used for installing the motor 1, the speed reducer 3, the torque sensor 4, the brake 5 and the main truss 26 and the like. The base 27 is fixed on the ground by anchor bolts, the main truss 26 is fixed on the base 27, and the front and rear brackets 28 are fixed on the front and rear sides of the main truss 26;

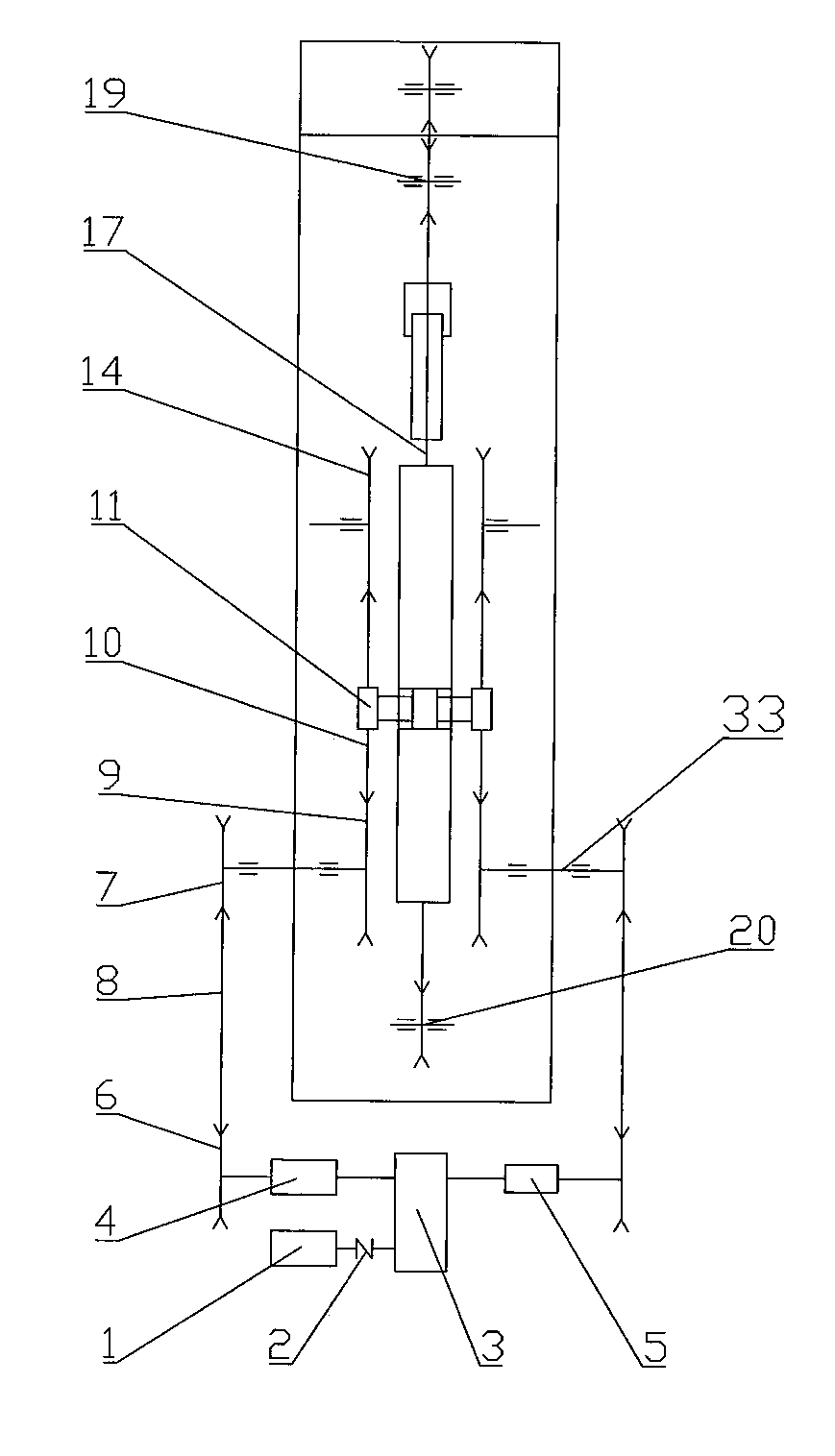

[0033] refer to figure 1 , figure 2 , image 3 and Figure 5 , the transmission part includes a motor 1, a coupling 33, a reducer 3, a torque sensor 4, a brake 5, two front synchronous pulleys 7, two rear synchronous pulleys 6, two synchronous belts 8, two lower Double-row sprocket 9, chain 10, reversing device, two upper double-row sprockets 14, two upper double-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com