booster press

A technology for presses and racks, applied in the field of booster presses, can solve problems such as high noise, and achieve the effects of reducing moving distance, long service life and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

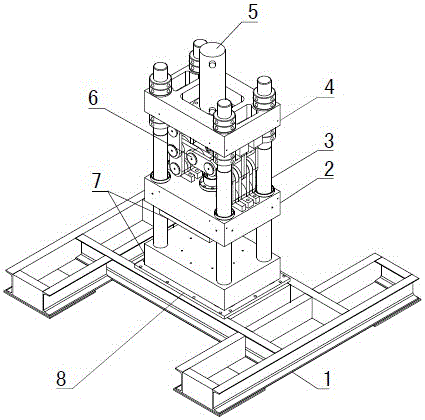

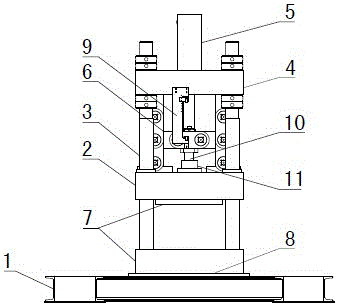

[0023] Figure 1~3 It is the best embodiment of the present invention. Figure 1~3 The present invention will be further explained.

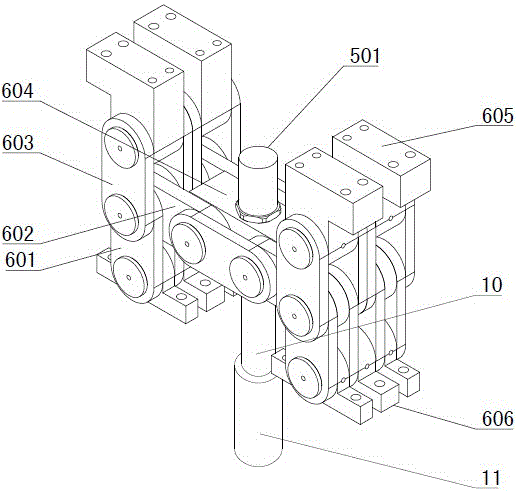

[0024] A variable speed pressurizing mechanism includes a connecting block 604, two hinge mechanisms symmetrically hinged on both sides of the connecting block 604, and a guide device for guiding the connecting block 604. The hinge mechanism includes an output rod 601 hinged together in a star and an input The lever 602 and the swing lever 603, the hinge mechanism is hinged on the connecting block 604 through the input lever 602, the output lever 601, the input lever 602 and the swing lever 603 swing in the same plane or in parallel planes, and the free end of the output lever 601 is the power The output terminal. The input rod 602, the output rod 601 and the swing rod 603 of the hinge mechanism change the speed of the connecting block 604, and output through the output rod 601, so that the pressure output by the output rod 601 is increased, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com