Electric jack for vehicle

A jack, electric technology, applied in the direction of vehicle maintenance, workshop equipment, transmission, etc., can solve the problem that the jack does not have a lifting unit, and the vehicle cannot be jacked or lifted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

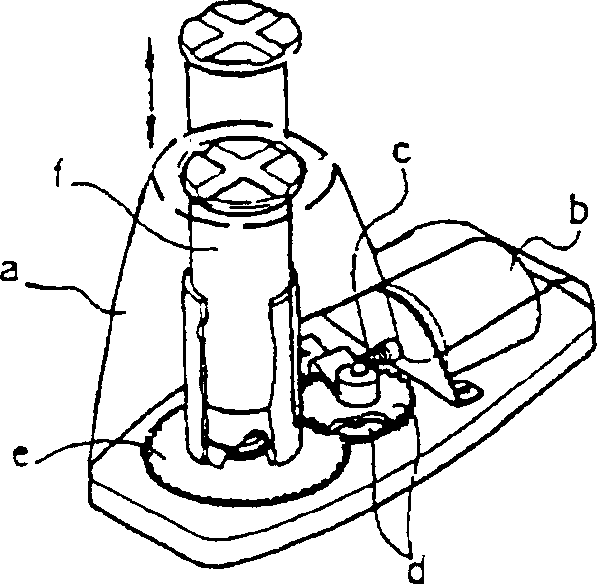

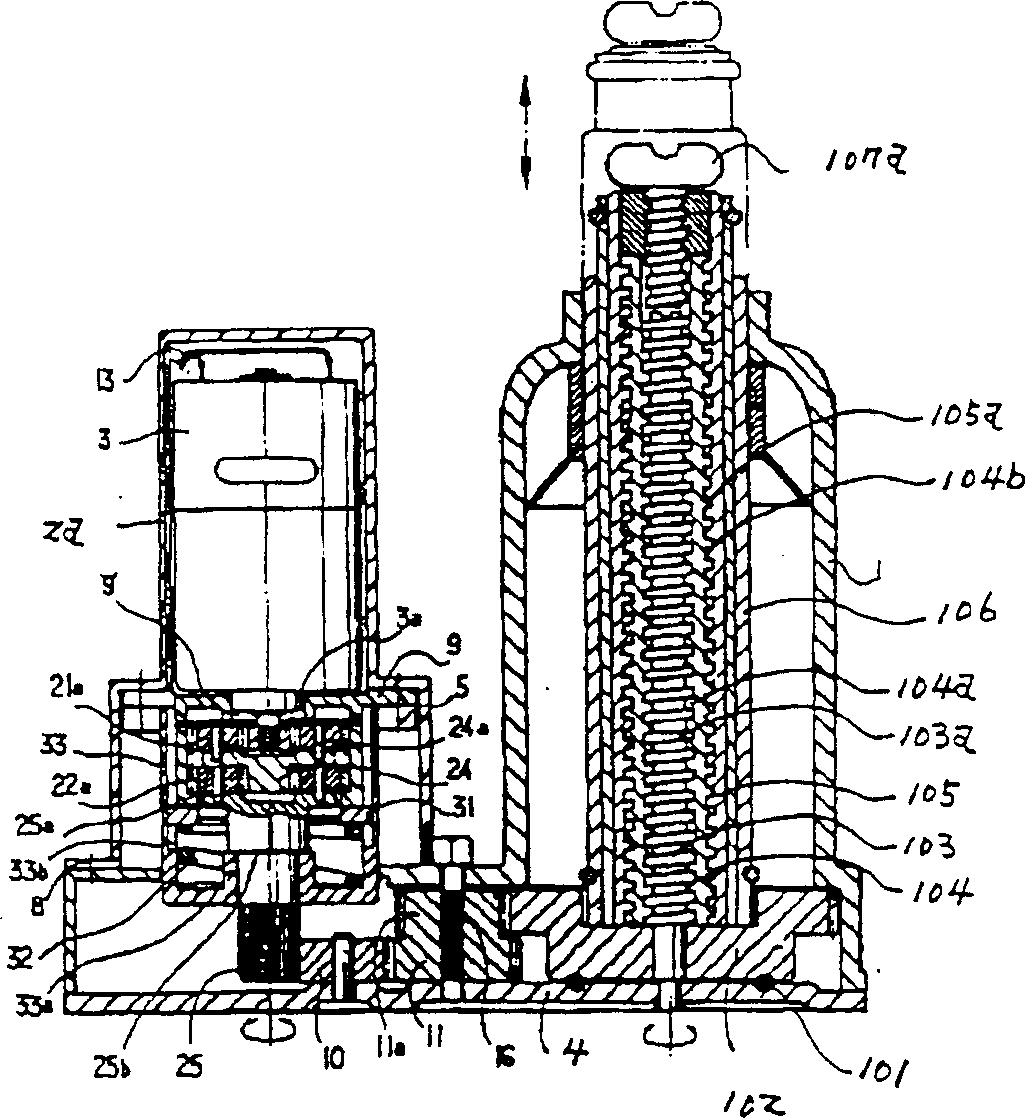

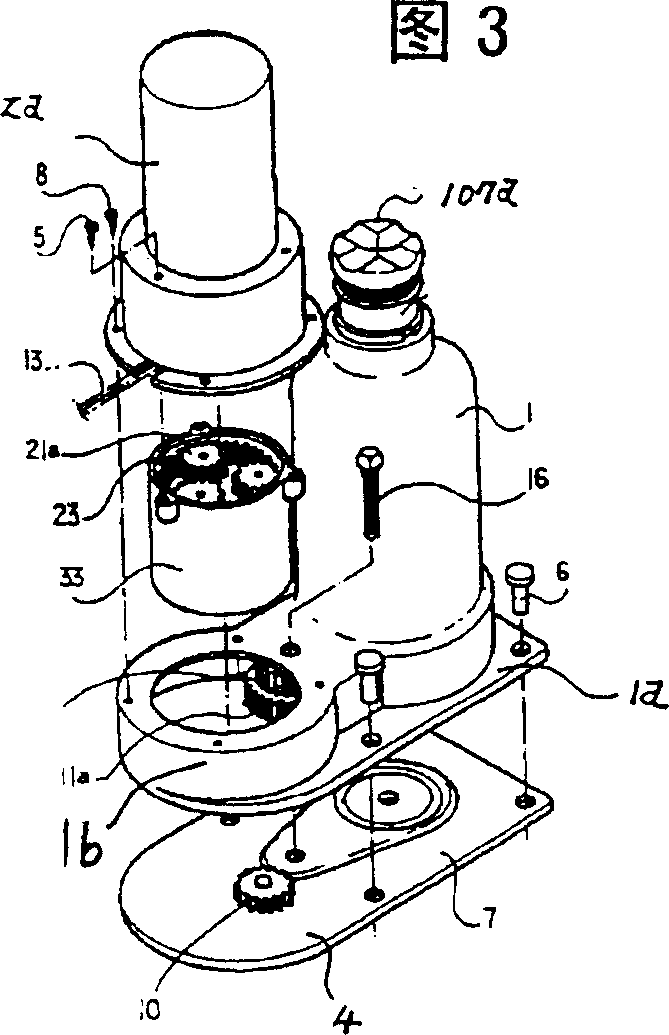

[0022] Reference is now made to the drawings in which identical or similar parts are labeled with the same reference numerals throughout the various figures.

[0023] Fig. 3 is an exploded perspective view of an electric jack according to a preferred embodiment of the present invention. As shown, the jack of the present invention has a unitary body. The overall body includes a lifting unit casing 1 with a base flange 1a at its lower end. A lifting unit is housed in the lifting unit casing 1 . The power transfer unit is located in the bottom of the lifting unit casing 1 . An annular casing 1b is formed on the bottom side of the lifting unit casing 1, and this annular casing 1b is combined with the lifting unit casing 1 to form a structure. Installed on the base flange 1a, the bottom of the jack is closed. The motor casing 2a is segmented cylindrical and is vertically placed in the annular casing 1b. The lower part of the motor casing 2a with a large radius is located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com