Three-phase permanent-magnet linear motor octupole nine-slot stator winding

A permanent magnet linear motor and stator winding technology, which can be applied to electric components, the shape/style/structure of winding conductors, electrical components, etc., and can solve the problems of reducing motor output stability, poor back EMF waveform, and large footprint. , to achieve the effect of improving motor efficiency, good back EMF waveform, and improving slot full rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

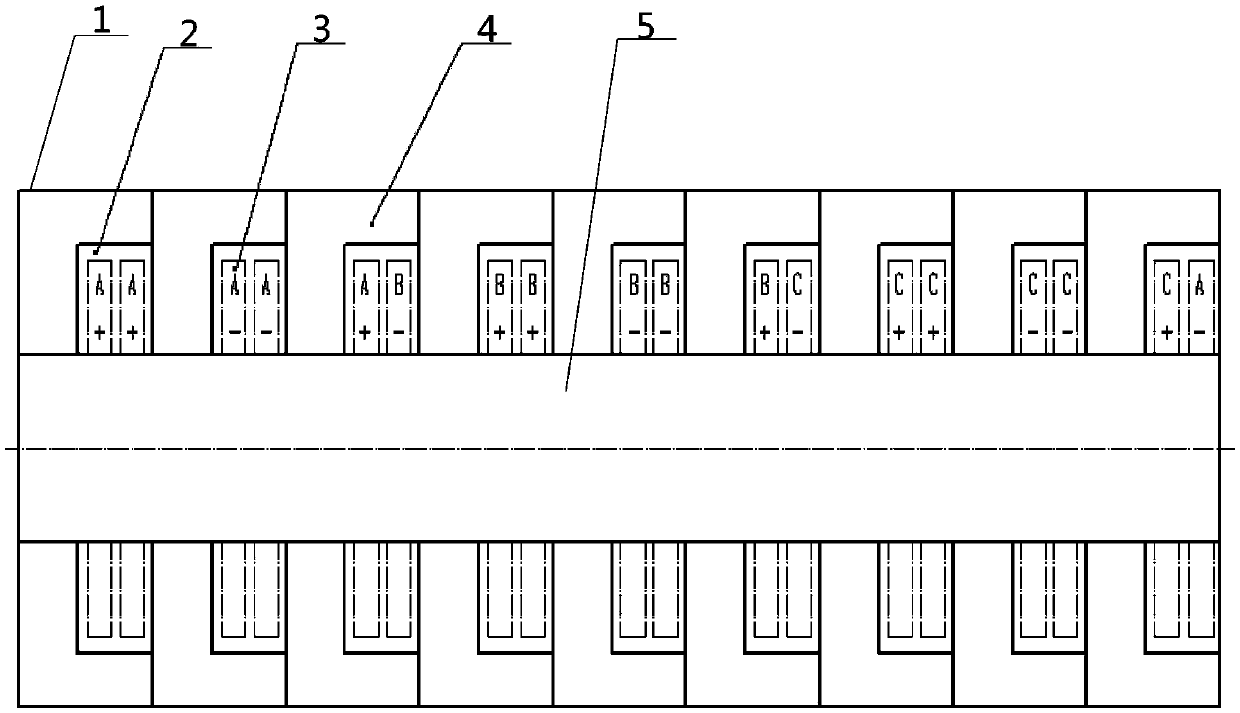

[0015] see figure 1 The illustrated three-phase permanent magnet linear motor eight-pole nine-slot stator winding includes a three-phase permanent magnet linear motor stator winding 1, and the stator winding 1 includes a stator core and A, B, and C three-phase windings 3. A stator winding unit, the stator core is formed by stacking several silicon steel sheets 4, the stacking direction of the silicon steel sheets 4 is parallel to the axis of the casing (not shown in the figure), and the stator core formed after stacking is along the axial direction There are tooth slots 2 that are evenly distributed inside the stator. The stator winding of this embodiment is an eight-pole nine-slot winding structure in the fractional slot concentrated winding. The stator winding is composed of eight stator winding units in series, and each stator winding unit includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com