Blushless DC motor and blushless DC motor controller

A motor control and motor technology, which is applied in control systems, electromechanical devices, DC motor speed/torque control, etc., can solve the problems of not considering the influence of the bridge, and can not achieve high efficiency and low noise at the same time, and achieves the reduction of The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Hereinafter, embodiments of a brushless DC motor and a brushless DC motor control device according to the present invention will be described in detail with reference to the drawings.

[0064] First, the reduction of noise and the determination of the angle θ 0 Methods.

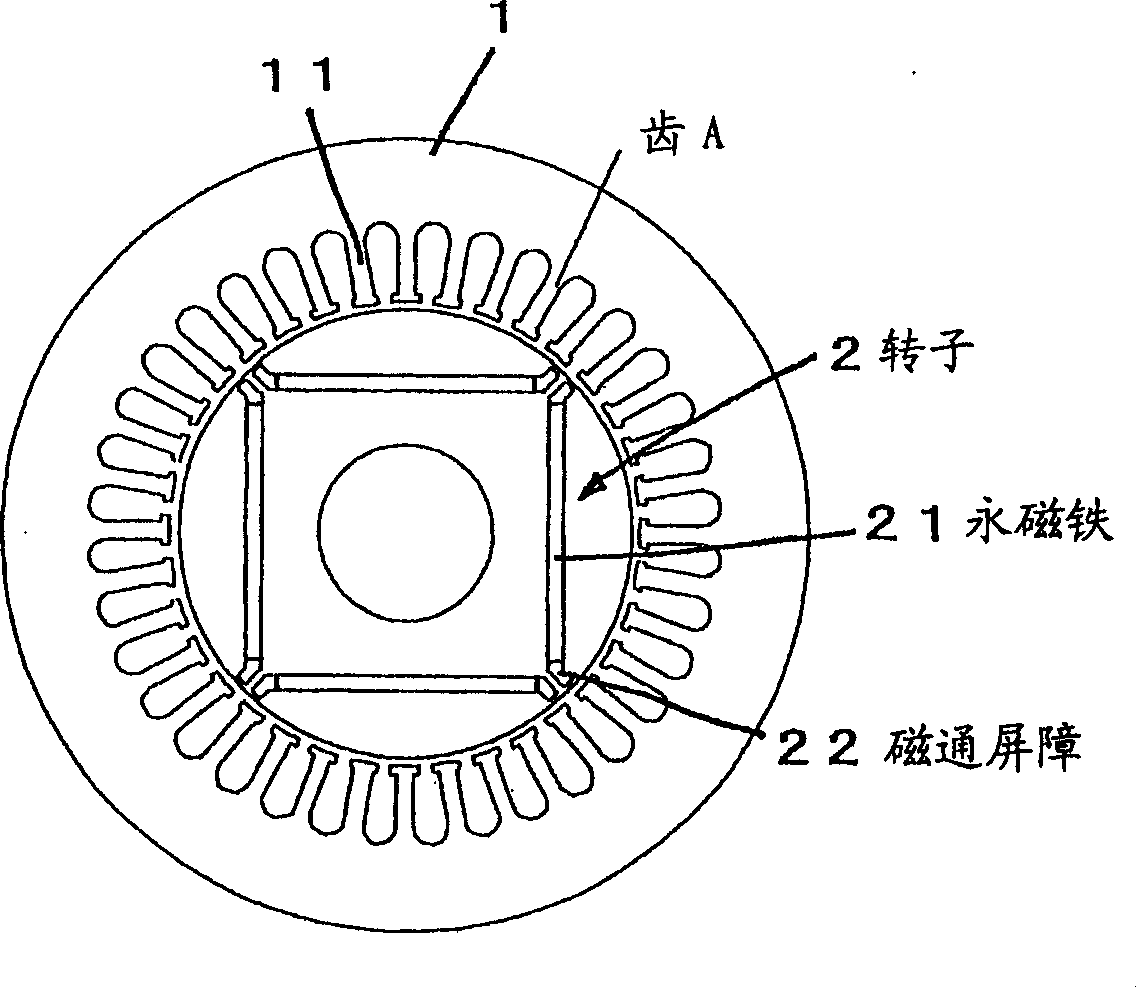

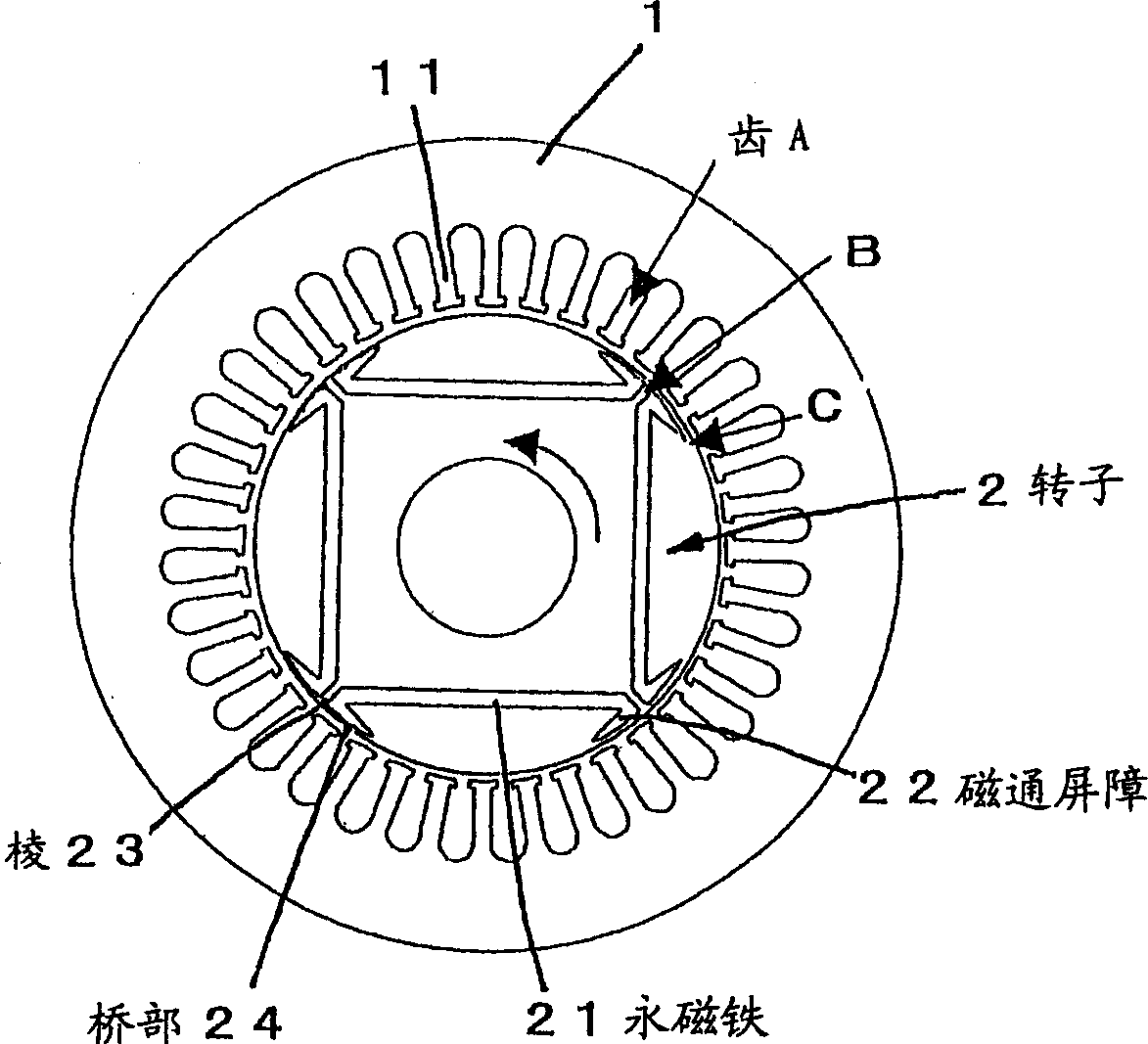

[0065] figure 1 It is a vertical cross-sectional view showing the structure of a conventional brushless DC motor, including a stator 1 formed with a plurality of teeth 11, and a permanent magnet 21 housed inside, and has a for extending from both ends of the permanent magnet 21 to the outer surface. The rotor 2 is protected by a barrier 22 which prevents short-circuiting of the magnetic flux.

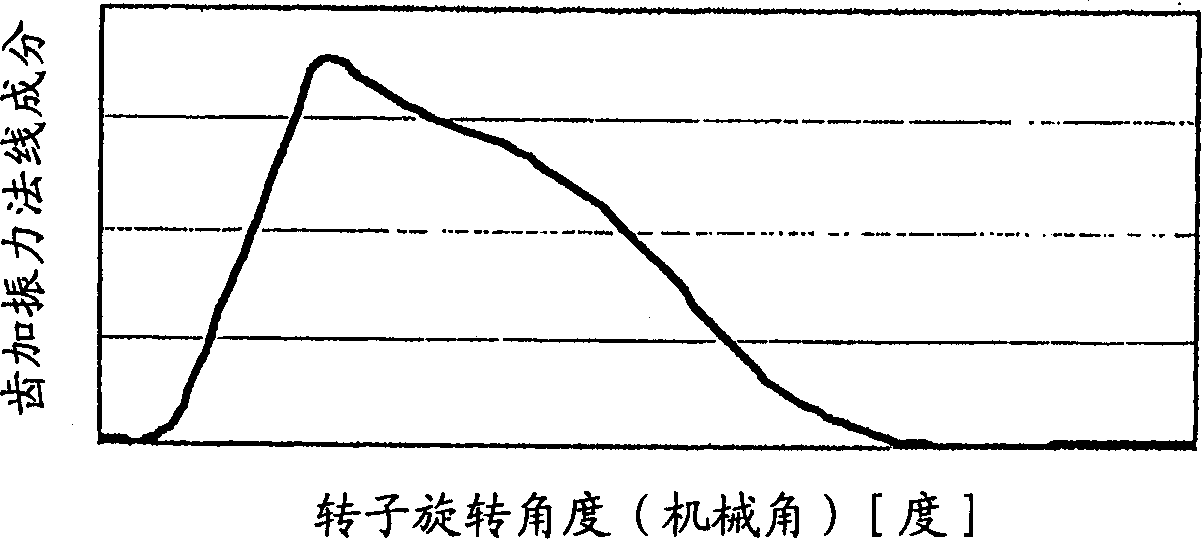

[0066] figure 2 It is a graph showing the vibration force (normal component) applied to the tooth A when a brushless DC motor having a rotor whose width of the barrier 22 is close to the thickness of the permanent magnet 21 is in operation.

[0067] From figure 2 It can be seen that as the rotor 2 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com