Mechanical and electrical integrated injection molding device for workpiece production and processing

An electromechanical and integrated technology, which is applied in the field of electromechanical integrated injection molding devices for workpiece production and processing, can solve problems such as uneven molding materials, air bubbles, and uncertain movement cycles of piston rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

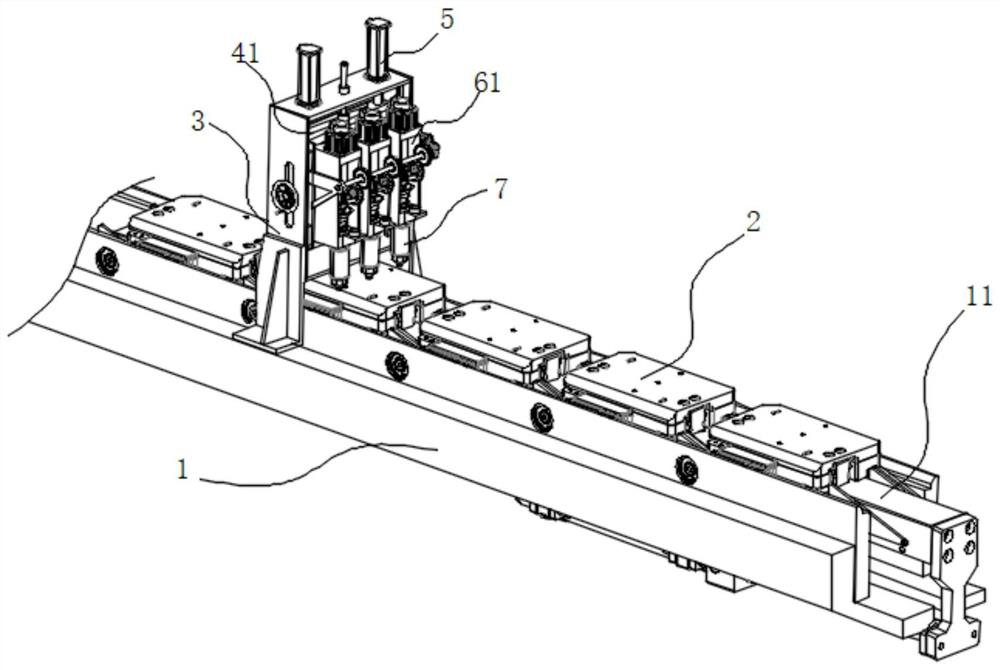

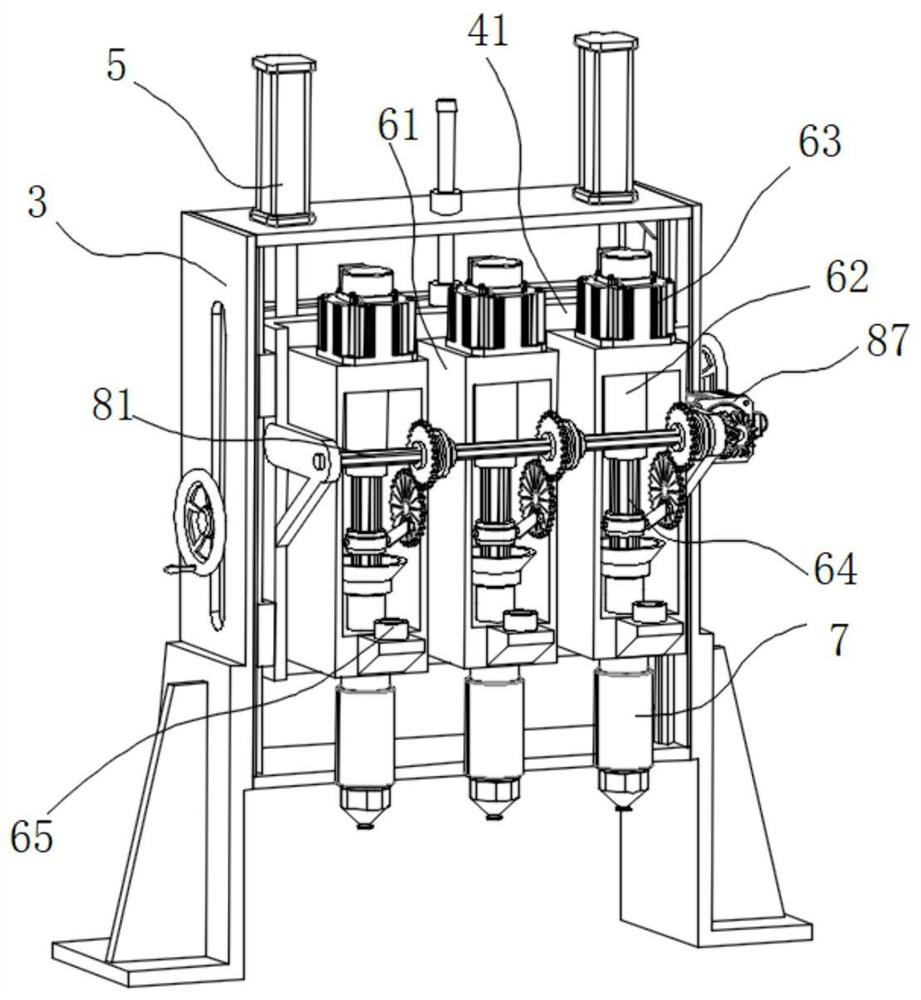

[0041] see figure 1 , in an embodiment of the present invention, an electromechanical integrated injection molding device for workpiece production and processing, including a conveying tank 1, a plurality of molds 2 are evenly placed in the conveying tank 1, and a step-by-step conveying mold 2 is provided at the bottom of the conveying tank 1 The advancing slide bar 11, the gantry 3 is fixed on the conveying trough 1;

[0042] The gantry 3 is provided with an elevating platform 41 that can slide up and down, and a plurality of connecting seats 61 are slidably distributed in the elevating platform 41 along the direction perpendicular to the advancing direction of the conveying trough 1, and each connecting seat 61 is provided with Injection molded components7.

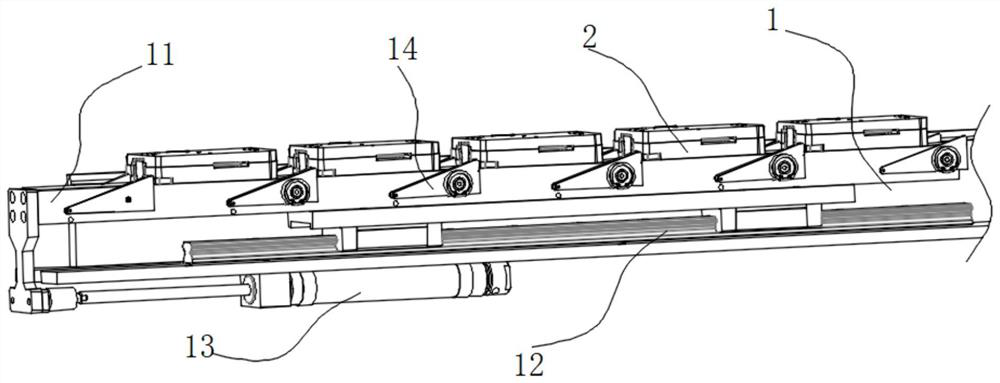

[0043] see figure 2 , in this embodiment, the bottom of the delivery tank 1 is fixed with a guide rail 12, and the guide rail 12 is slidably provided with a pusher slide bar 11, the width of the push slide bar 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com